Transfer case structure and hinge joint type dumper

A transfer case and articulated technology, which is applied to vehicles, vehicle components, fluid steering mechanisms, etc. that are inclined to carry motion, can solve the problems of large influence of the transmission shaft angle, insufficient steering force, and loss of control of the whole vehicle, so as to improve driving. The effect of safety, improved passing ability, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

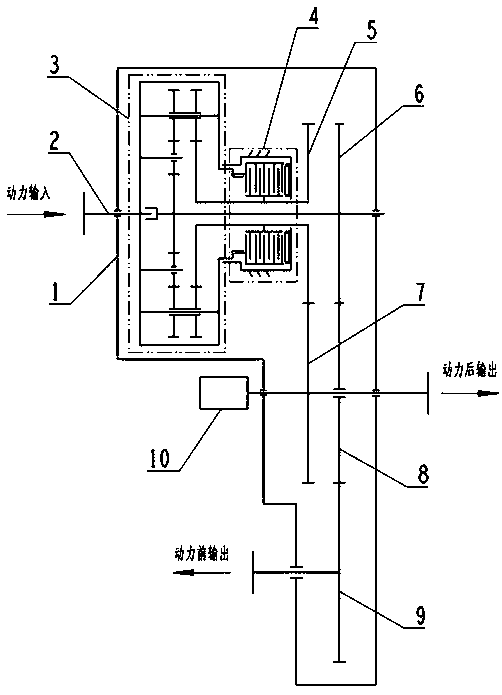

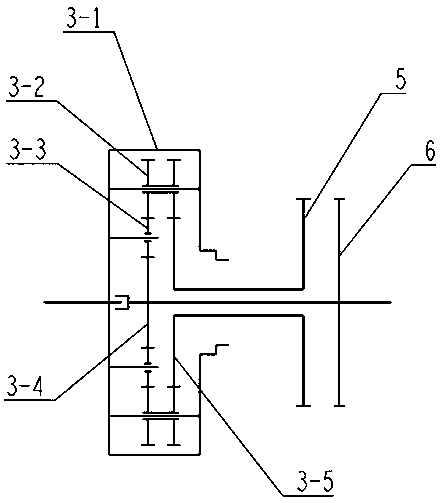

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following implementations are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0037] The transfer case structure of the embodiment of the present invention can be used for the articulated dump truck of the embodiment of the present invention; the articulated dump truck of the embodiment of the present invention has the transfer case structure of the embodiment of the present invention.

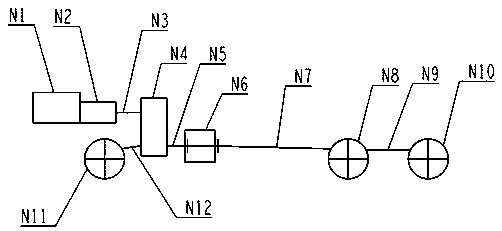

[0038] Such as figure 1 As shown, the power source is the engine N1, which is shifted through the gearbox N2 to control the driving speed and driving force. The power output by the gearbox N2 is transmitted to the transfer case N4 through the transmission shaft N3, and the transfer case N4 passes through the transmission shaft N12 respectively. and transmission shaft N5 to transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com