Evaporation and heat-exchange periodic water replenishment device

An evaporative heat exchanger and evaporative heat exchange technology, applied in the direction of heat exchanger types, direct contact heat exchangers, water shower coolers, etc., can solve the problem of reduced efficiency, high relative humidity environment, difficult to guarantee The water film thickness is controlled in the optimal state and other issues to achieve the effect of high evaporation heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

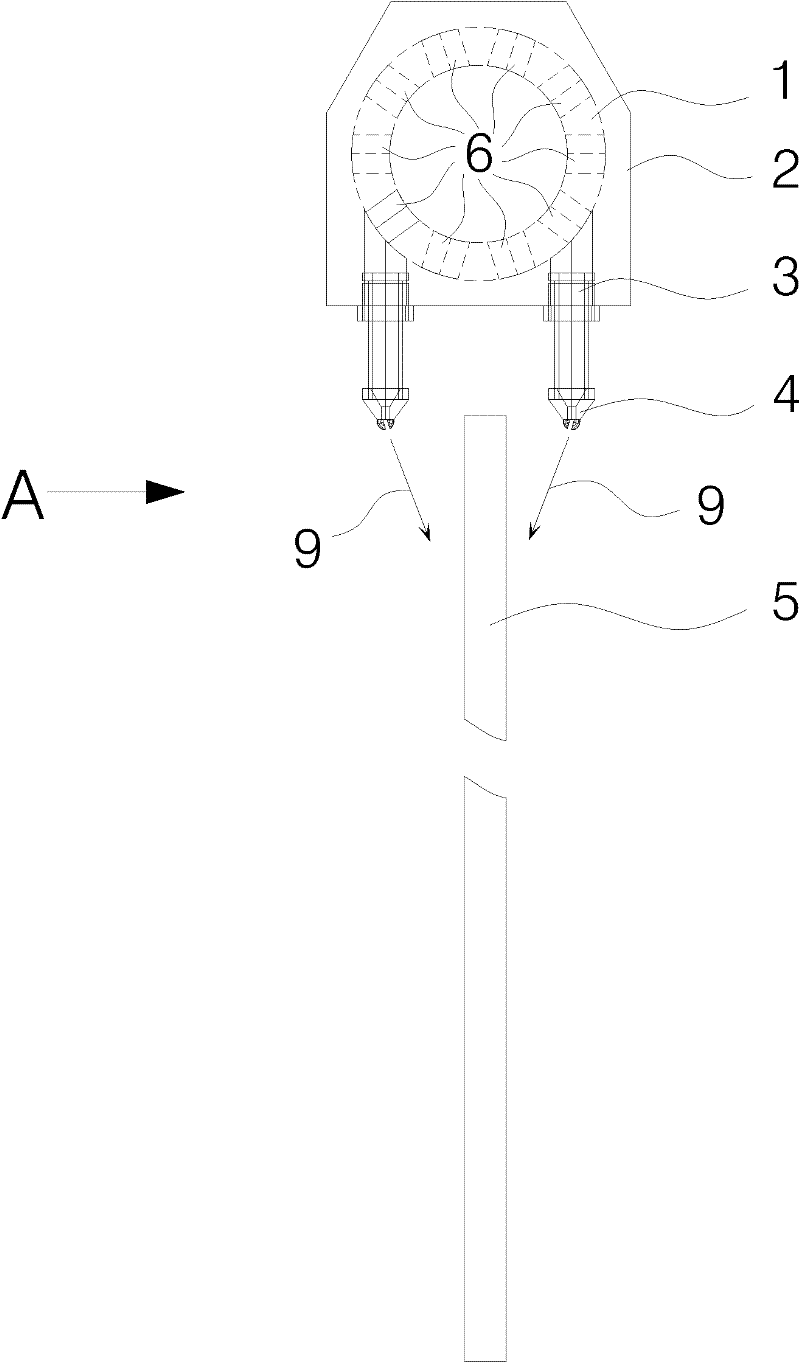

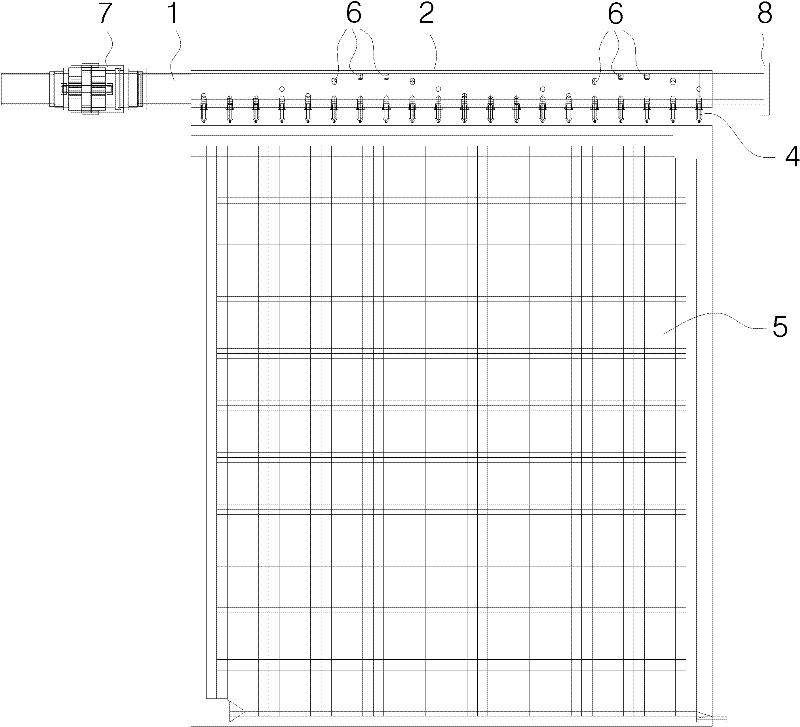

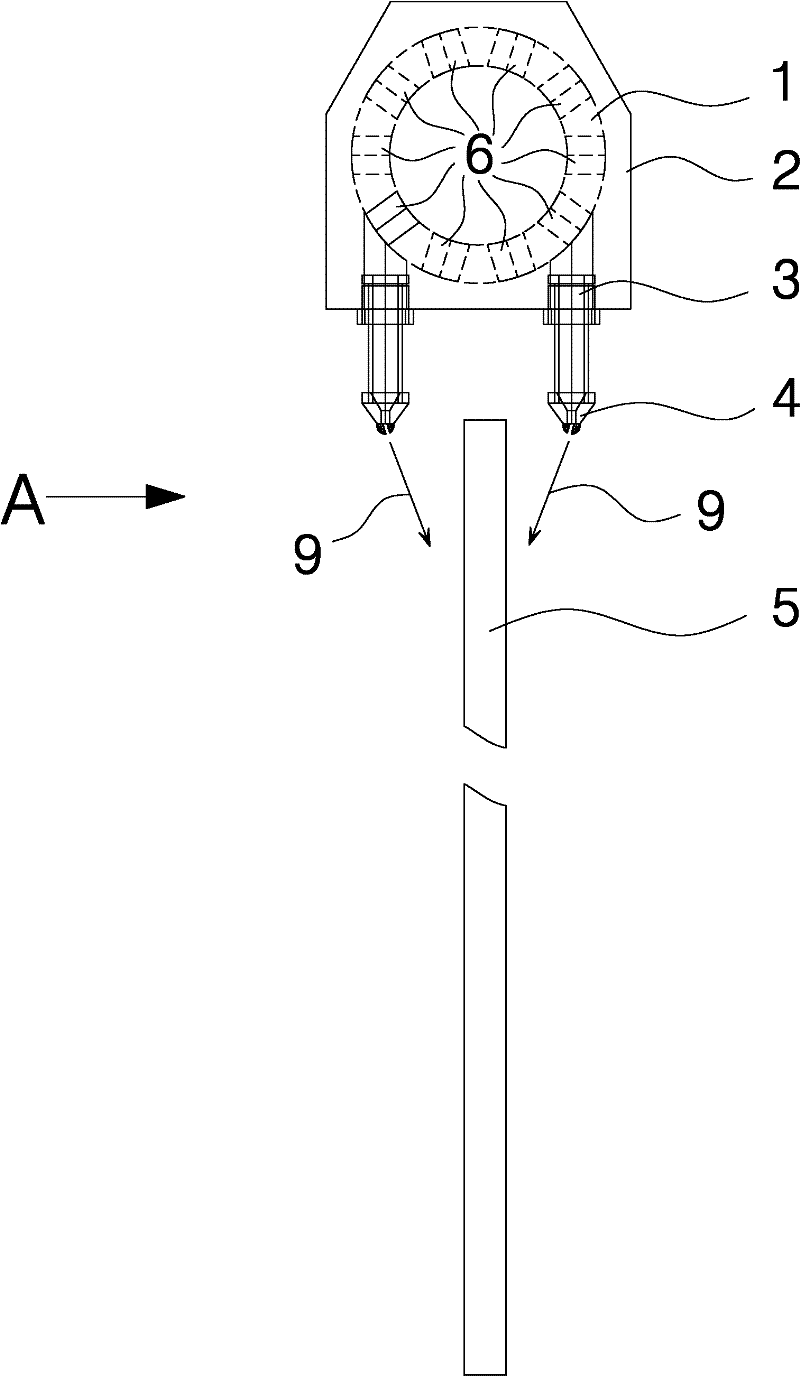

[0017] like Figure 1~2 The evaporative heat exchange periodic water replenisher shown includes a diversion body 2 and a rotating water supply pipe 1 installed in the diversion body 2. A plurality of diversion ports 3 are arranged on the diversion body 2 at intervals, and each diversion port 3 is provided with Nozzles 4 are installed, and a plurality of replenishment holes 6 are provided on the wall of the rotating water replenishment pipe 1. When the rotating water replenishment pipe 1 rotates relative to the diversion body 2, each replenishment hole 6 is periodically and correspondingly arranged in the diversion flow. The shunt interface 3 on the main body 2 is turned on.

[0018] like Figure 1~2 As shown, before using the evaporative heat exchange cycle water replenisher, the input end of the rotary water replenishment pipe 1 is first connected to the replenishme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com