Low-power consumption vibration wire-type strain acquisition system adopting wireless sensor network technology

A wireless sensor and network technology, applied in the field of low-power vibrating wire strain acquisition system, can solve the problems of test data drift, unstable performance, and insignificant improvement, so as to get rid of the dependence on power supply, test performance stability, and result Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

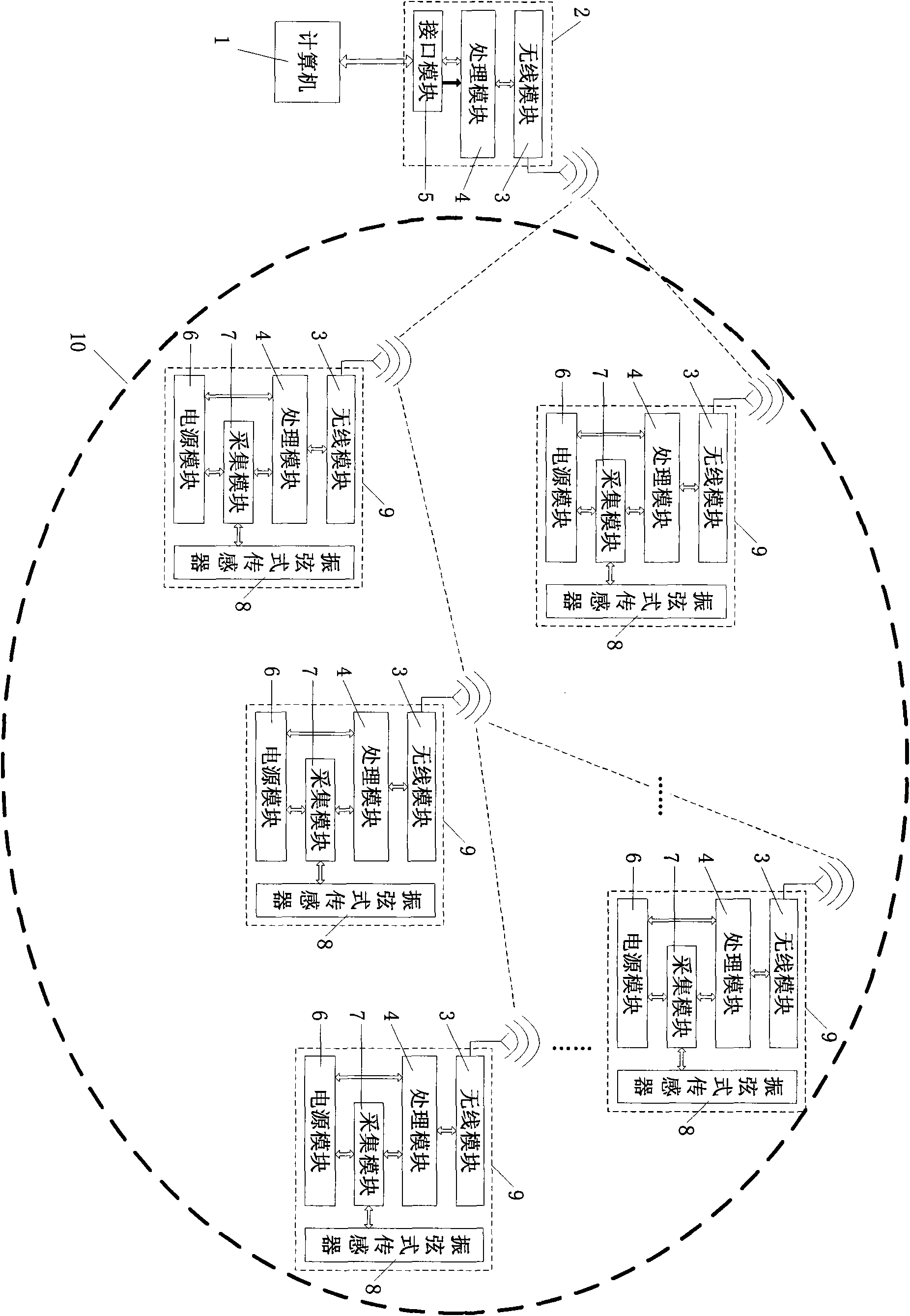

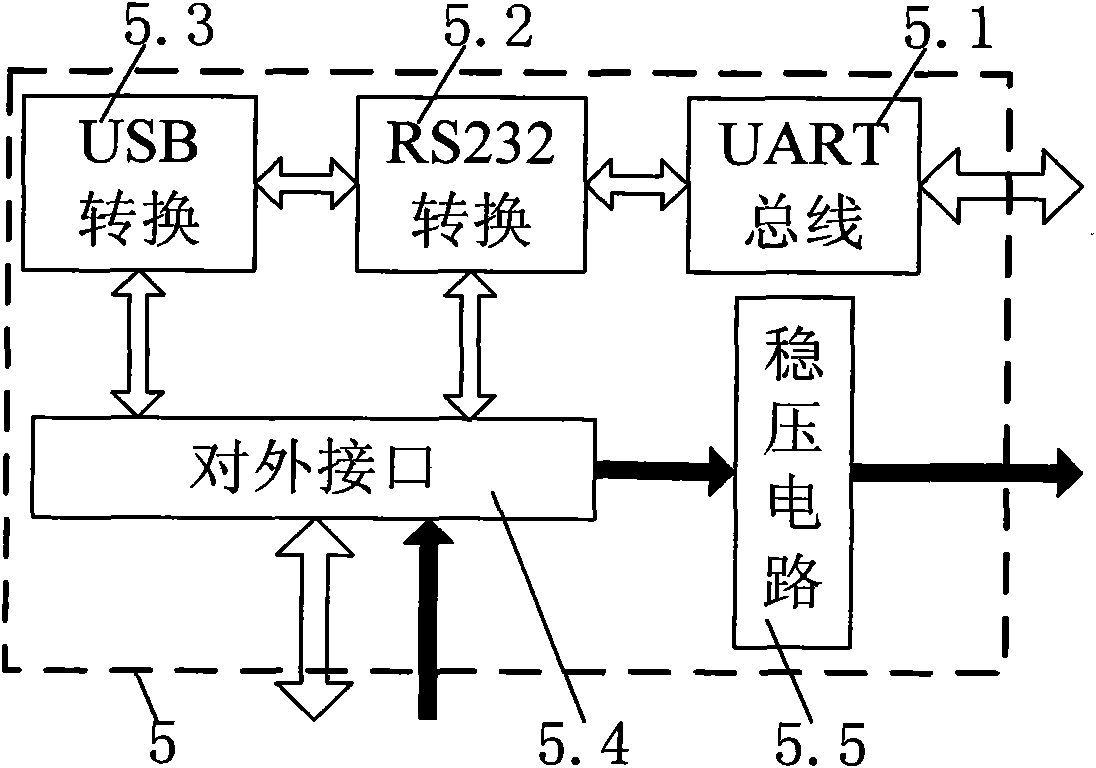

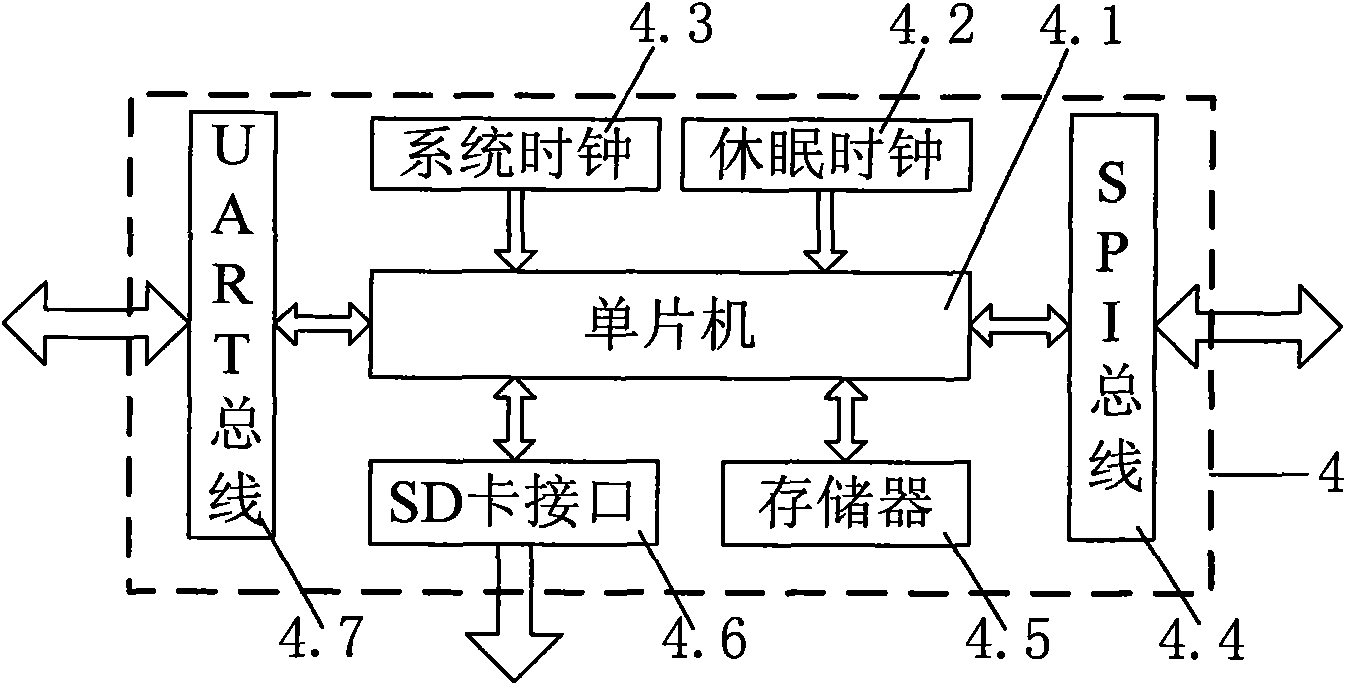

[0019] Such as figure 1 As shown, the low-power vibrating wire strain acquisition system using wireless sensor network technology includes a computer 1, a wireless control base station 2 and a wireless strain sensor network 10, and the wireless strain sensor network 10 is composed of several wireless low-power vibrating wire strain A network composed of acquisition units 9; the wireless control base station 2 includes an interface module 5, a processing module 4 and a wireless module 3, and the interface module 5 is connected to the processing module 4 and the wireless module 3 in sequence; the interface module 5 is connected to the computer 1; wireless low power consumption The vibrating wire strain acquisition unit 9 includes a wireless module 3, an acquisition module 7, a processing module 4, a power module 6 and a vibrating wire sensor 8; the power module 6 is connected to the acquisition module 7, the processing module 4, and the wireless module 3 in sequence, and the acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com