Control method for precision processing of micro-flow path abrasive flow based on flow volume mould

A control method and precision machining technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high speed and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings.

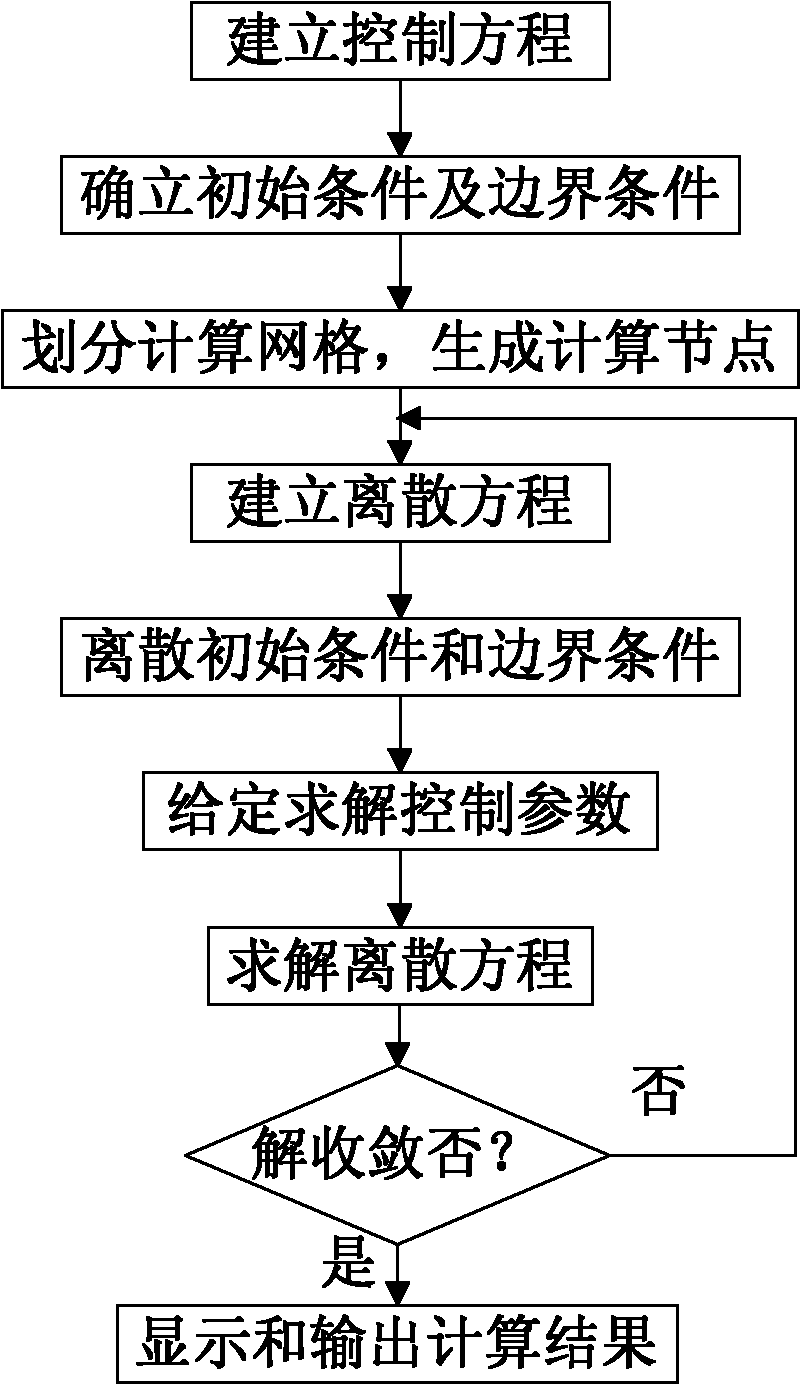

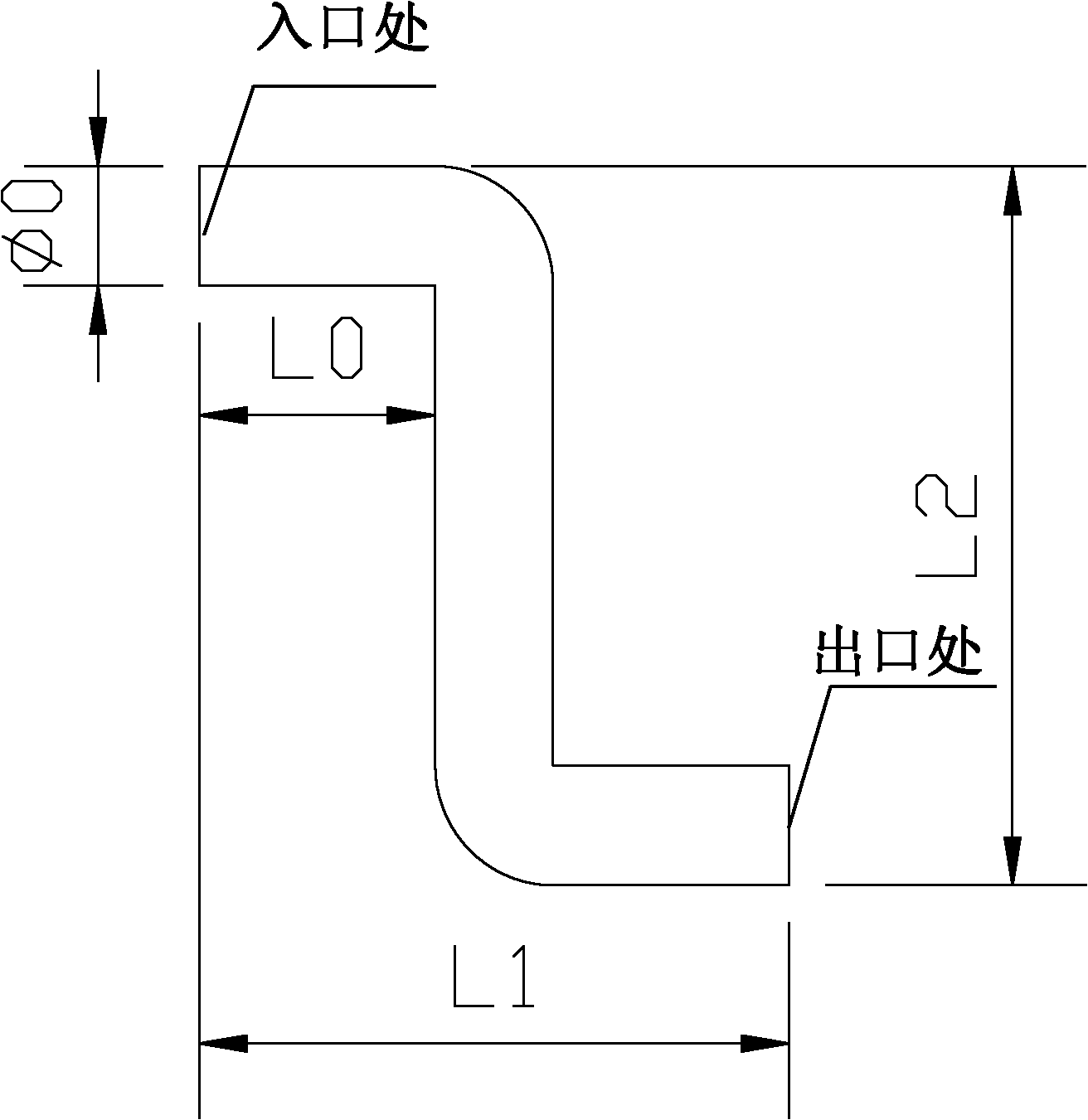

[0067] refer to Figure 1 to Figure 5 , a method for precision machining control of abrasive flow in micro-channels of molds based on fluid volume models, comprising the following steps:

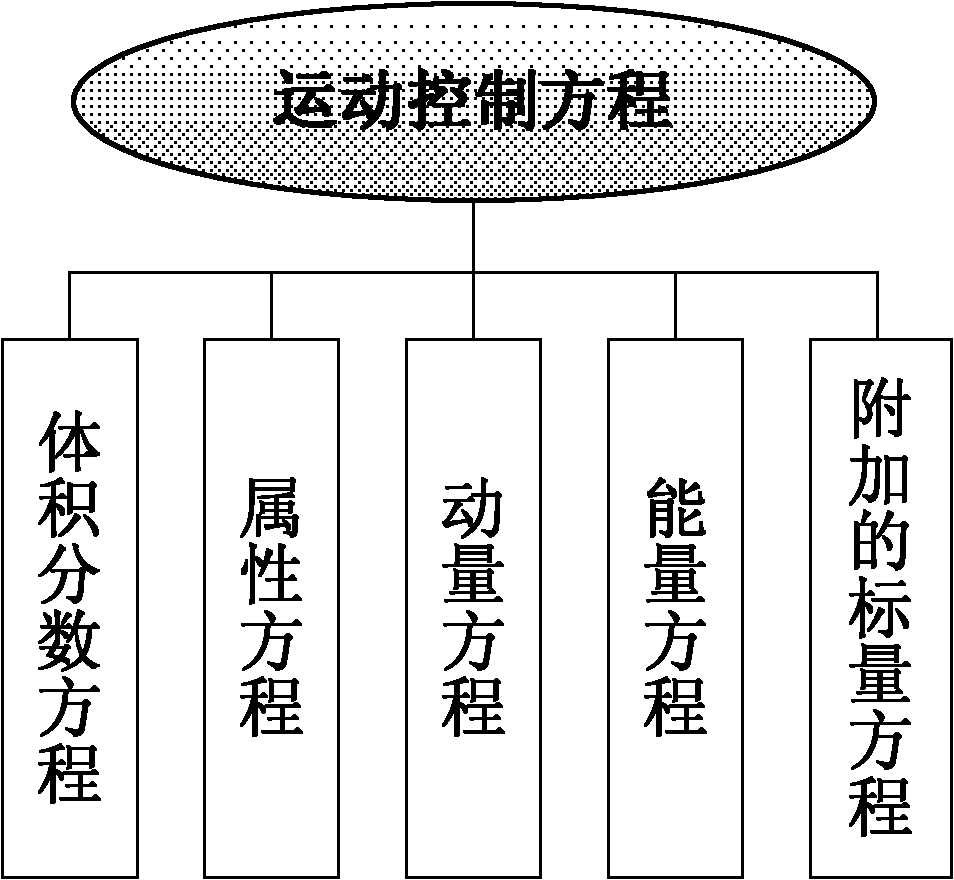

[0068] (1) Establish a mathematical model of abrasive flow motion

[0069] Without a correct and perfect mathematical model for abrasive flow motion, the simulation lacks a theoretical basis. Based on the basic theory of two-phase flow and continuum theory of abrasive flow, since there is no heat exchange, the continuity equation and momentum equation are directly used as the control equations use. Since the abrasive flow is mostly in the turbulent range, in general, the turbulence equation needs to be added. Therefore, the governing equation based on the combination of the fluid volume model and the SST turbulence model was established (see attached figure 1 ), the VOF model use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com