Coordination linkage method of intelligent transformer substation assisting production system

A smart substation and production system technology, applied in the electrical field, can solve problems such as low linkage intelligence, false linkage, sensor failure and environmental interference, so as to reduce manual intervention and ensure no misjudgment and misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

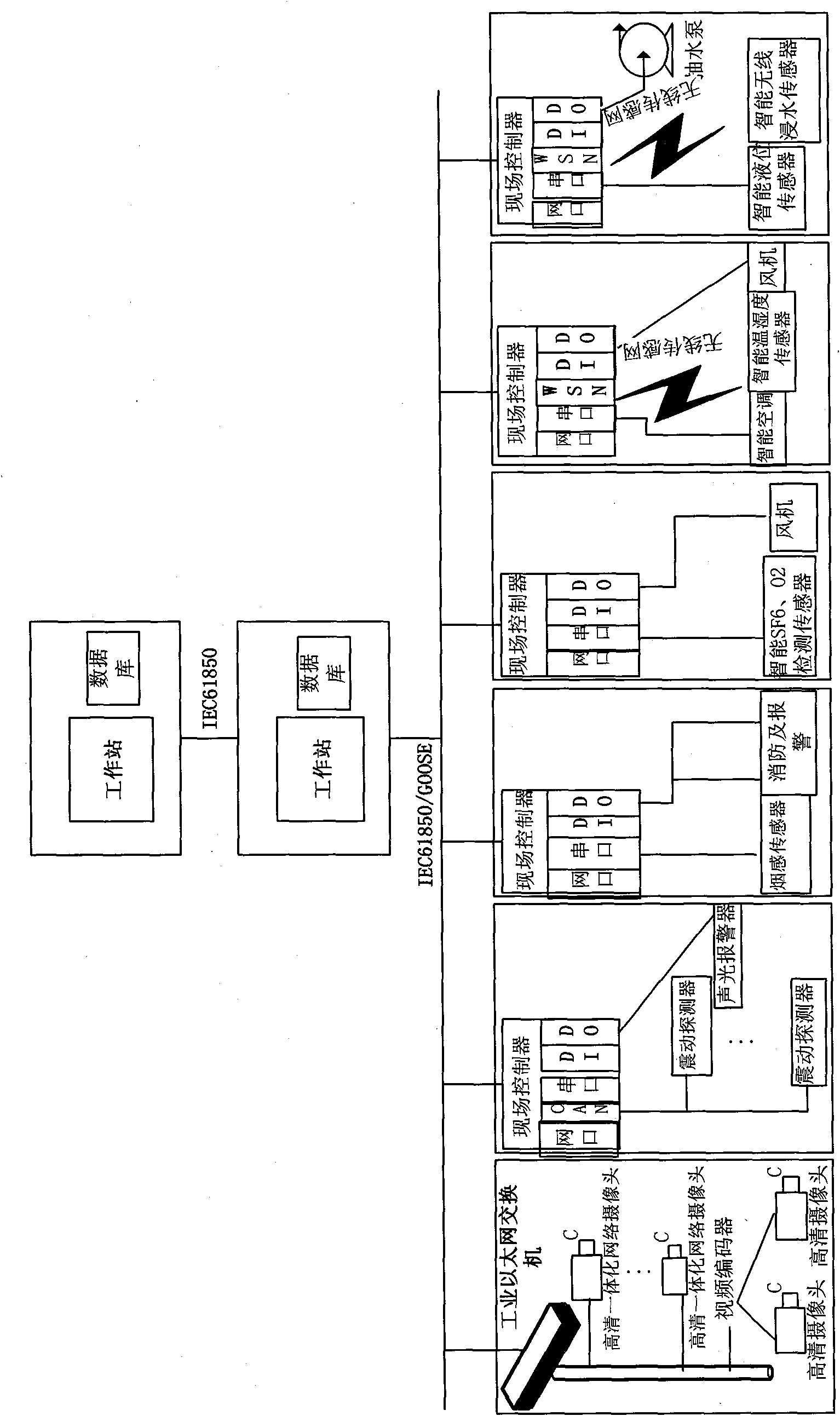

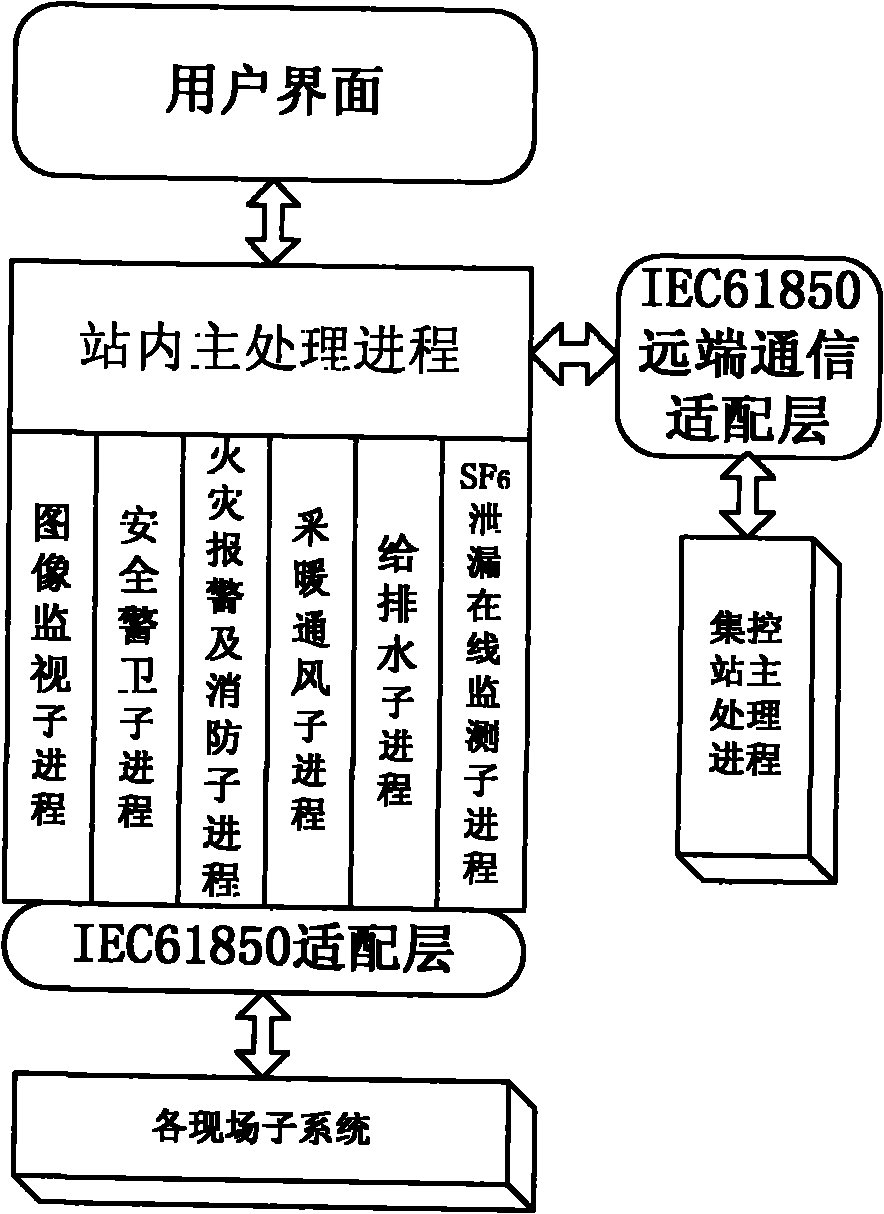

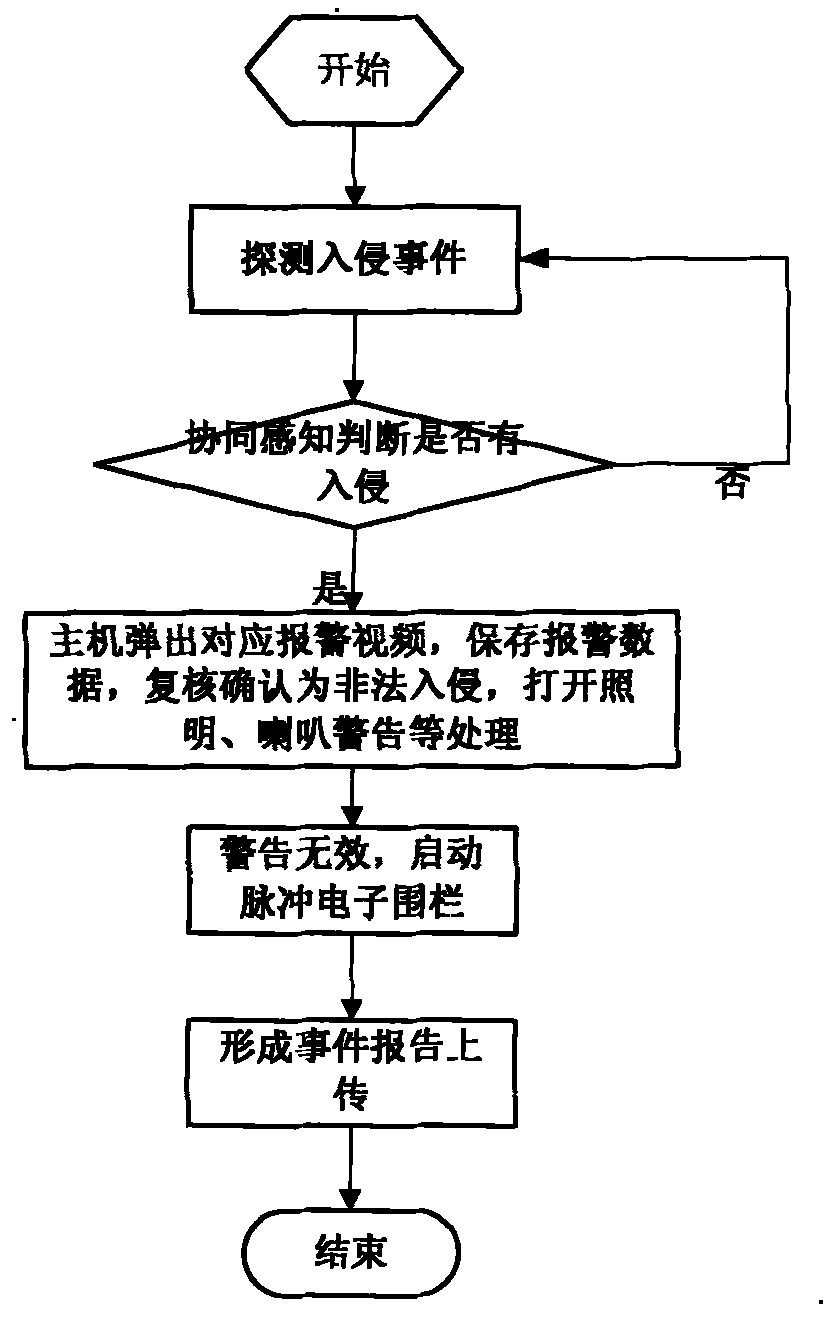

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The method of the invention divides the auxiliary production system of the substation into three layers, the first layer is the management host of the remote centralized control station, the second layer is the host in the station, and the third layer is the auxiliary production subsystems of the substation composed of intelligent sensor networks, and adopts The IEC61850 protocol unifies these three-layer devices into a large system (such as figure 1 shown).

[0023] The remote centralized control station management host and the station control host are composed of workstations, databases and corresponding software. The auxiliary production subsystem includes the following six subsystems:

[0024] Substation image monitoring subsystem;

[0025] Substation safety guard subsystem;

[0026] Substation fire alarm and fire protection subsystem;

[0027] Substation heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com