Drive motor of centrifugal fan

A technology for driving motors and centrifugal fans, applied in the field of motors, can solve the problems of inability to meet high speed, large fan friction loss, vibration, large volume, etc., and achieves the effect of compact structure, increased fan speed, and reduced fan volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

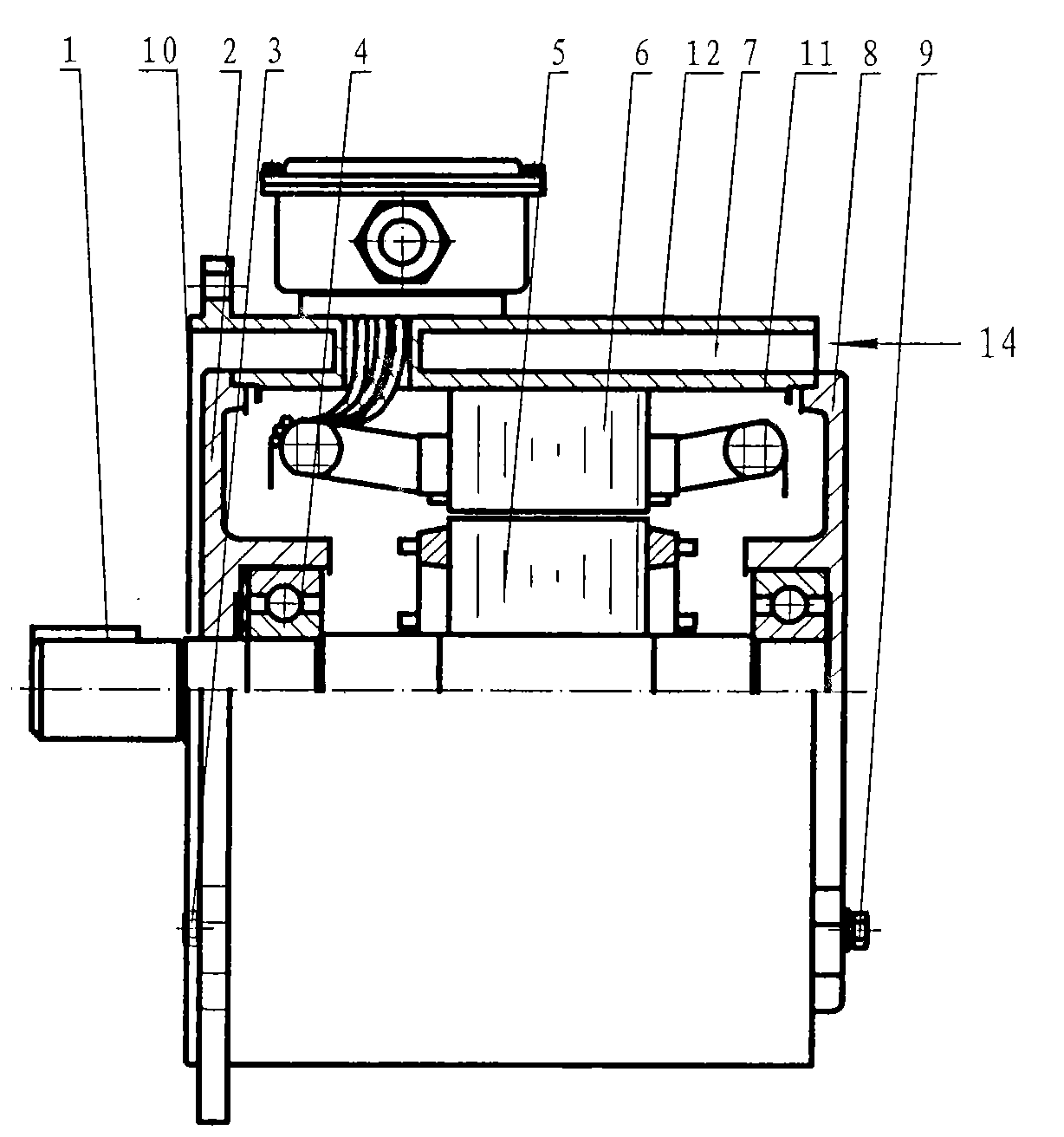

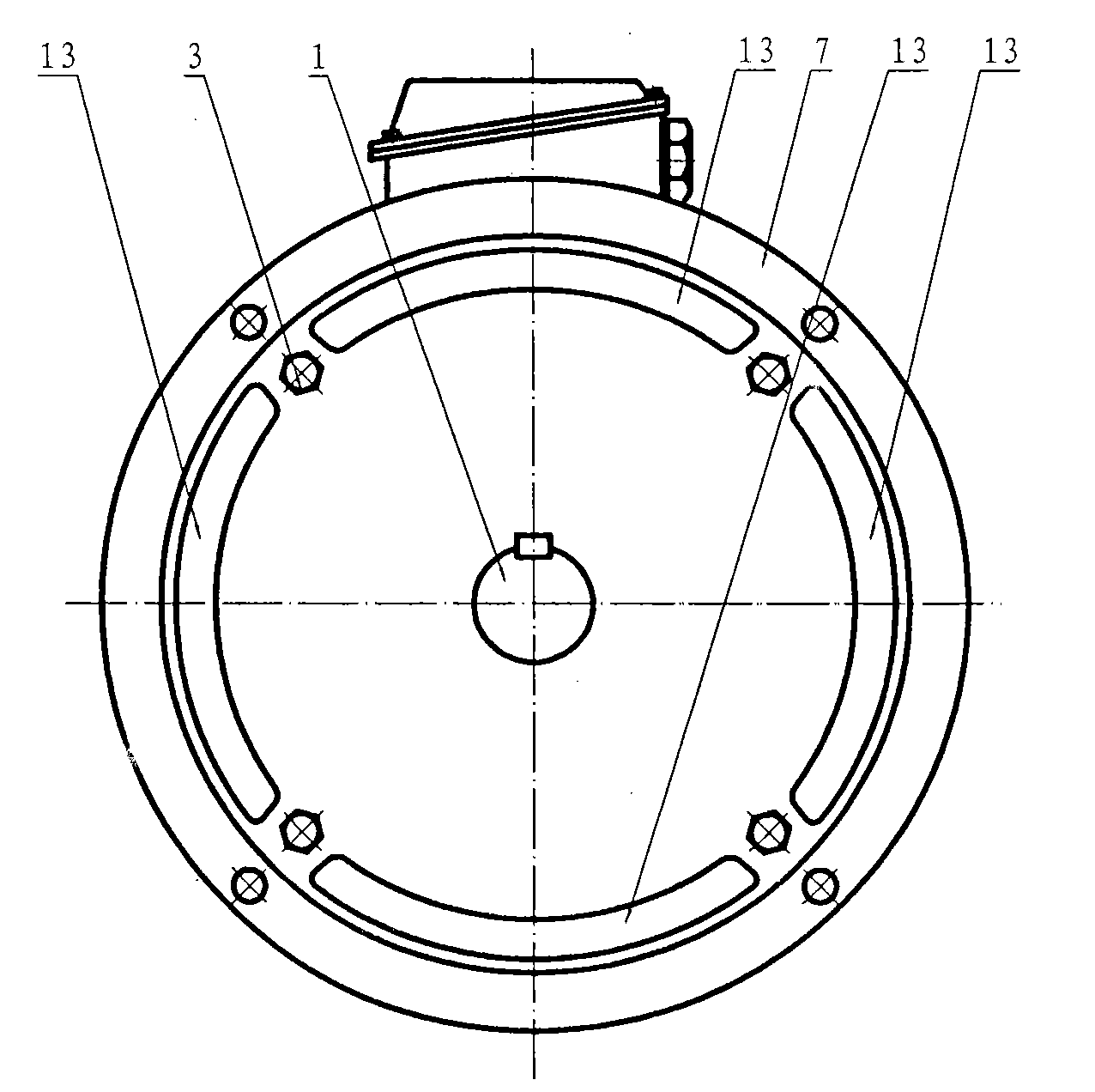

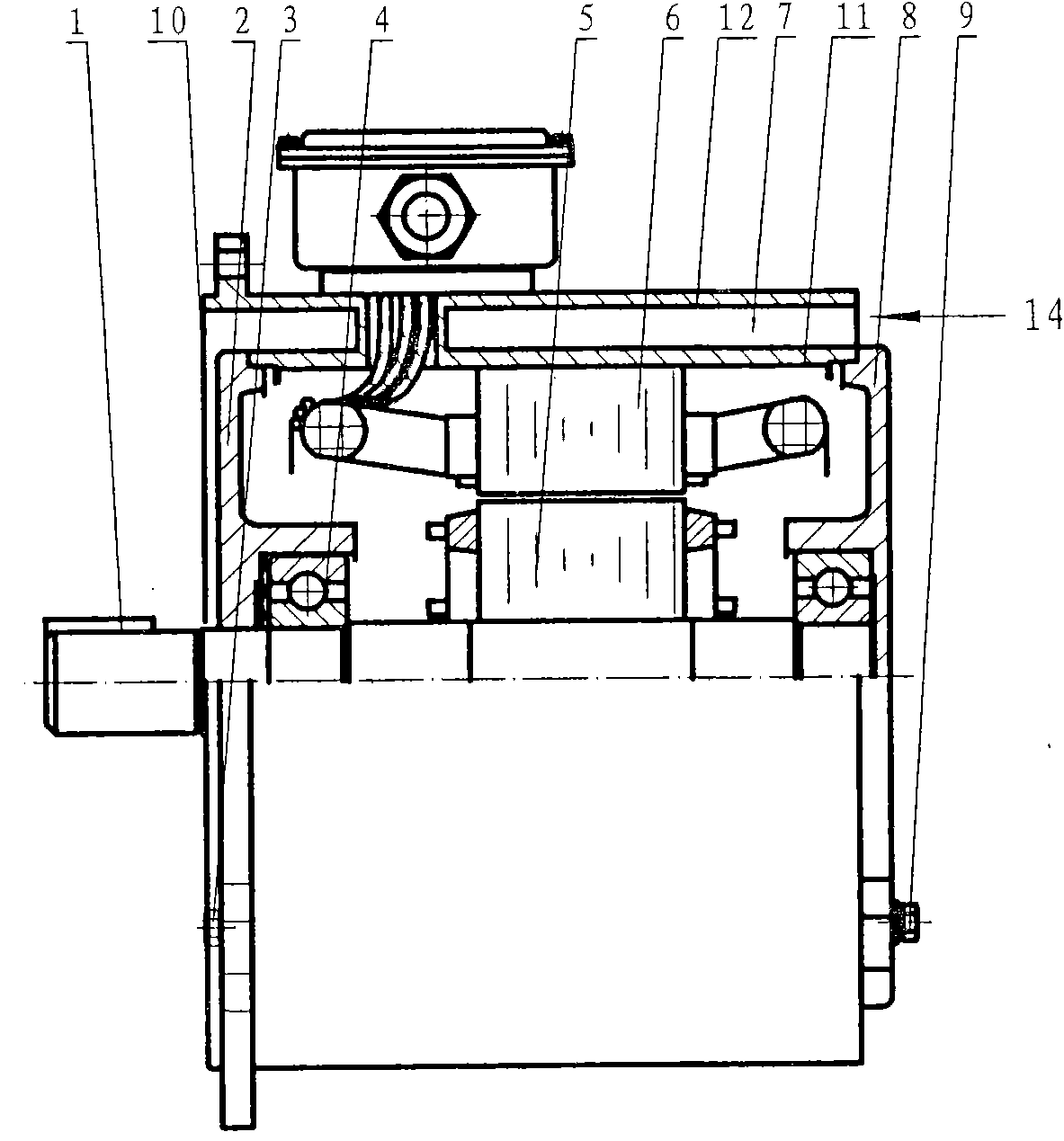

[0013] Such as figure 1 , figure 2 As shown, the stator 6 with windings is pressed into the machine base 7 with interference, the rotor 5 with bearings 4 respectively installed on the shafts 1 on both sides is placed in the center of the iron core of the stator 6 with windings, and the two ends of the machine base 7 are respectively installed with spigots. The front end cover 2 and the rear end cover 8, the bolt A3 passes through the mounting hole of the front end cover 2 and engages with the internal thread at one end of the machine base 7, and the bolt B9 passes through the mounting hole of the rear end cover 8 and engages with the internal thread of the other end hole of the machine base 7. The end surface 10 of one end of the double-layer machine base 7 has a heat dissipation air duct hole 13, and the heat dissipation air duct 14 is formed between the outer cylinder 12 of the machine base and the inner cylinder 11 of the machine base, and the heat dissipation air duct 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com