Planar transverse magnetic flux switch flux linkage permanent magnet linear motor

A technology of permanent magnet linear motor and transverse flux, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high cost and large amount of permanent magnets, and achieve low cost, less amount of permanent magnets, and fault tolerance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be specifically described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

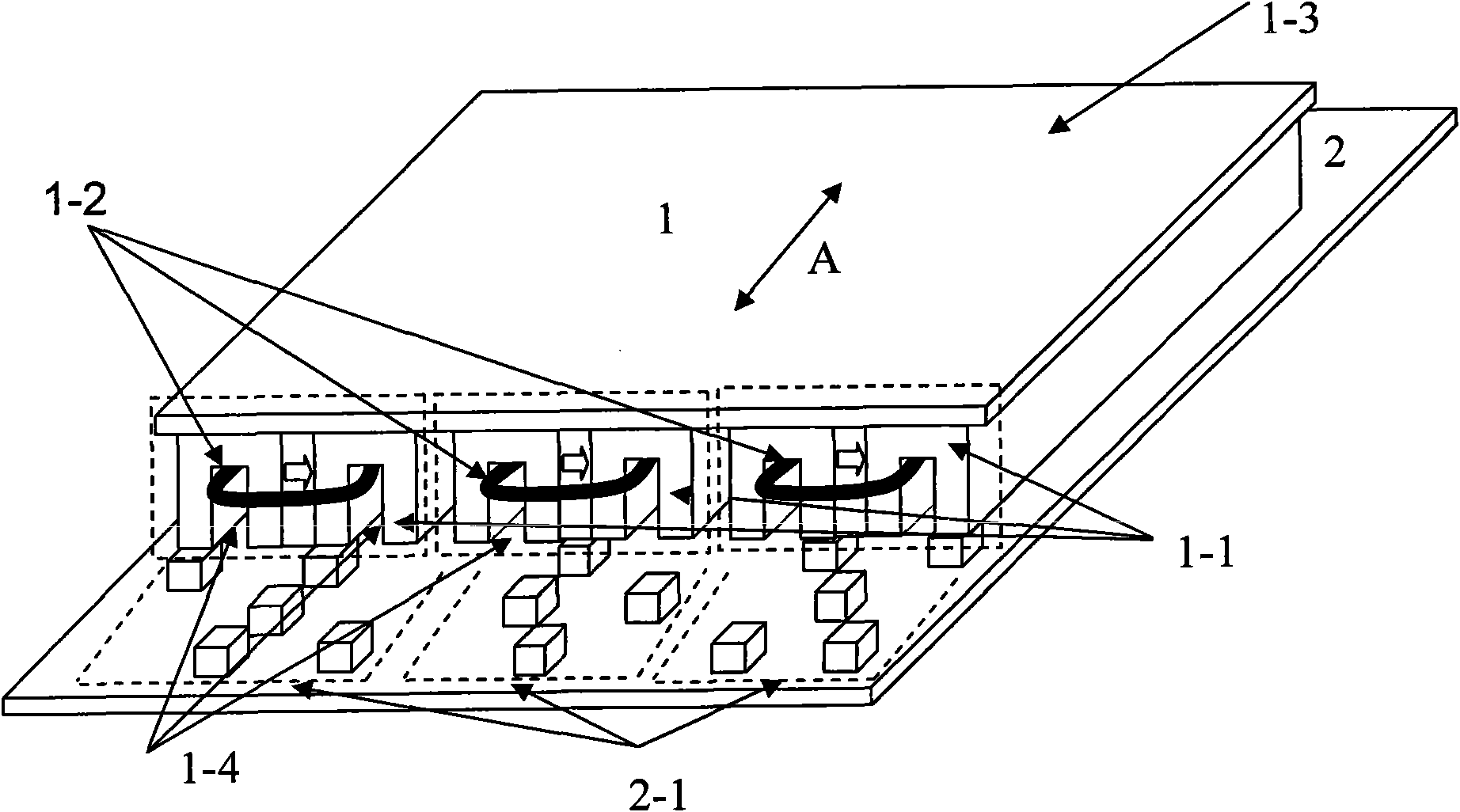

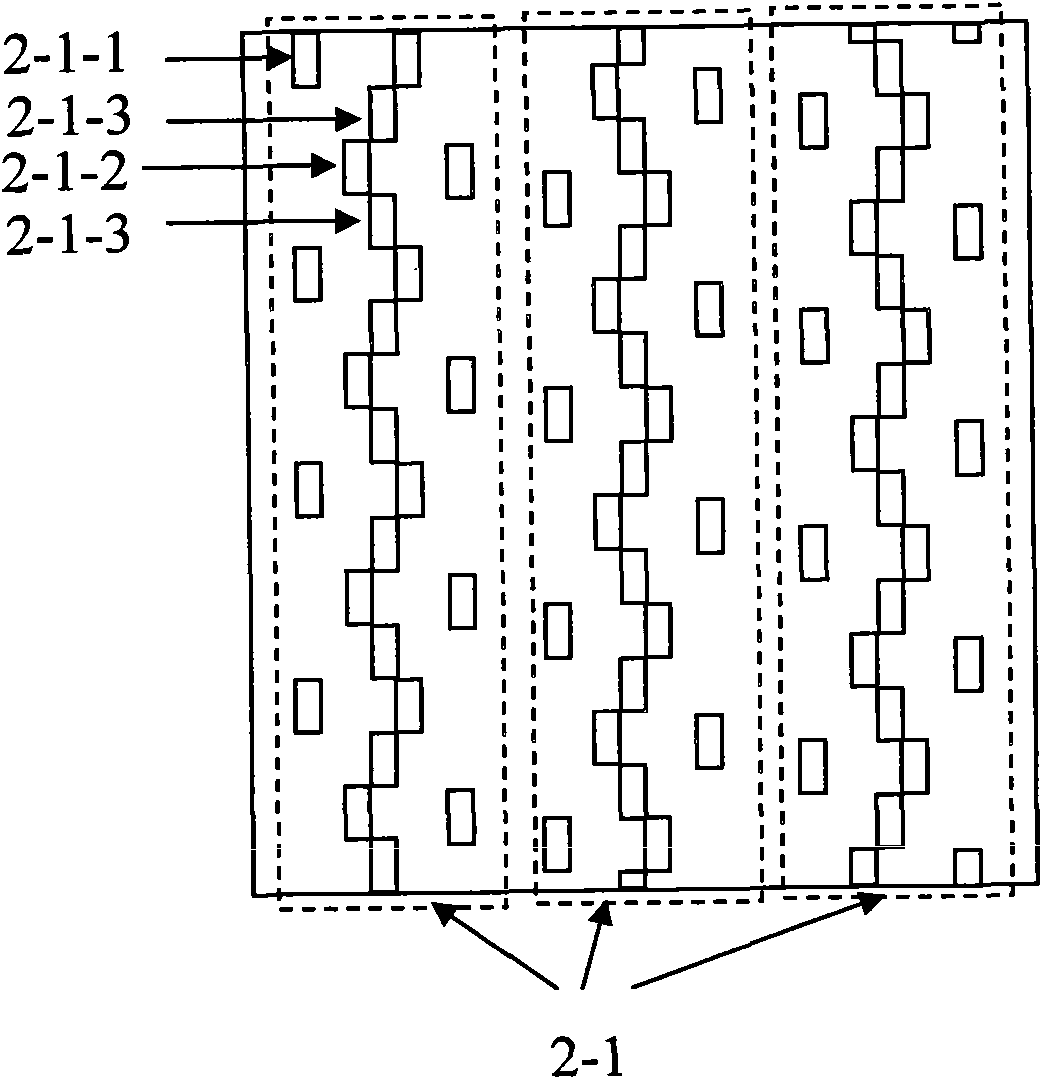

[0030] Such as figure 1 As shown, the planar transverse flux switching flux linkage permanent magnet linear motor of the present invention includes a mover 1 and a stator 2 .

[0031] The mover 1 is composed of a mover iron core, an armature winding and a non-magnetic bottom plate 1-3.

[0032] The mover iron core includes m groups of assembled E-shaped iron cores 1-1, and the E-shaped bottom planes of the m groups of assembled E-shaped iron cores 1-1 are arranged side by side with gaps on the non-magnetic base plate 1-3. On one side of the board, m is equal to the number of phases of the motor;

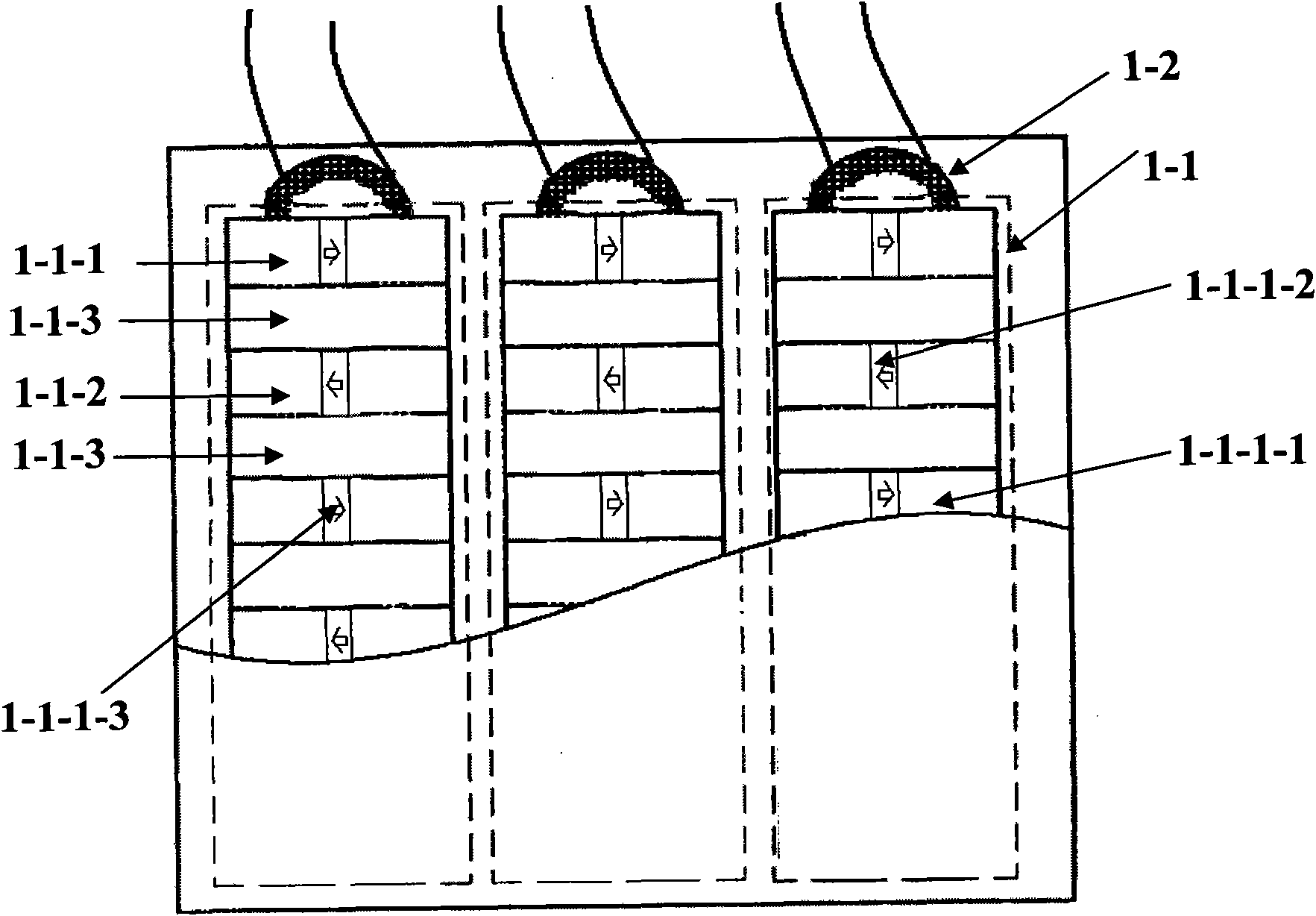

[0033] The assembled E-type iron core 1-1, each group consists of several first E-type magnetically permeable modules 1-1-1, several second E-type magnetically permeable modules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com