Method for automatically identifying LED load light source by using memory chip and implementation device

A memory chip and automatic identification technology, applied in the field of visual inspection, can solve the problems of inconvenient use, high light source temperature rise, and reduce the life of the LED load light source, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

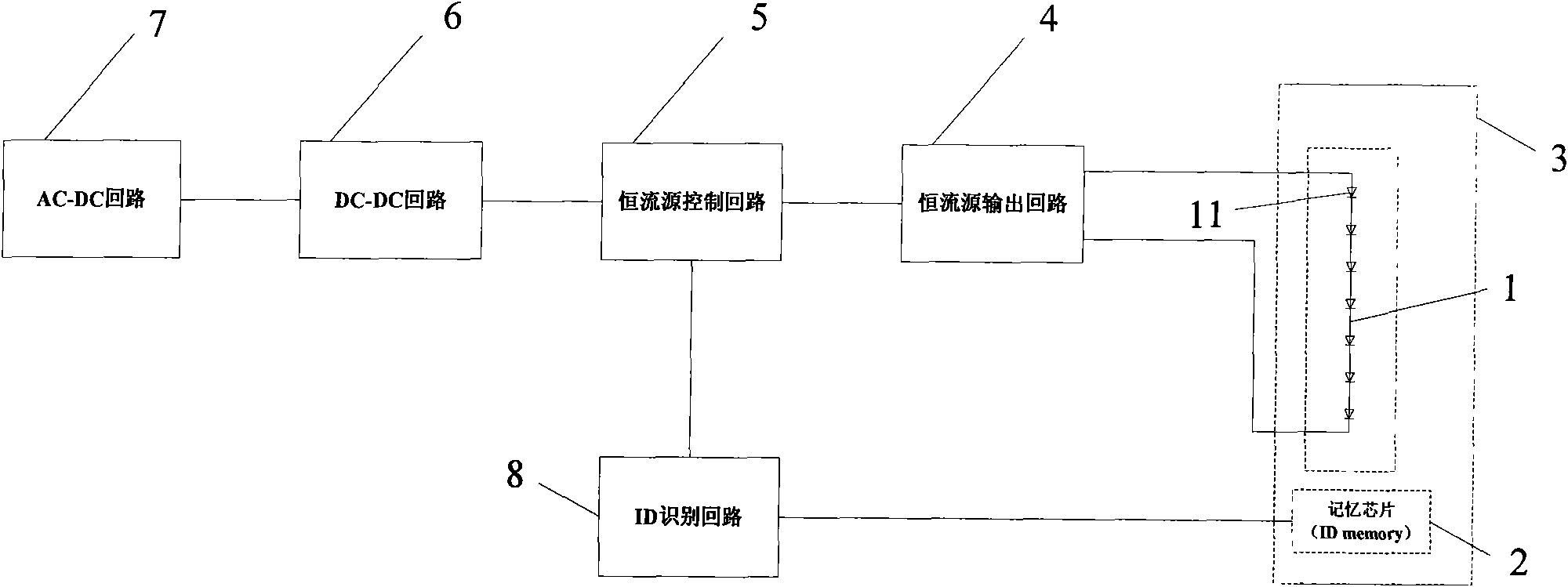

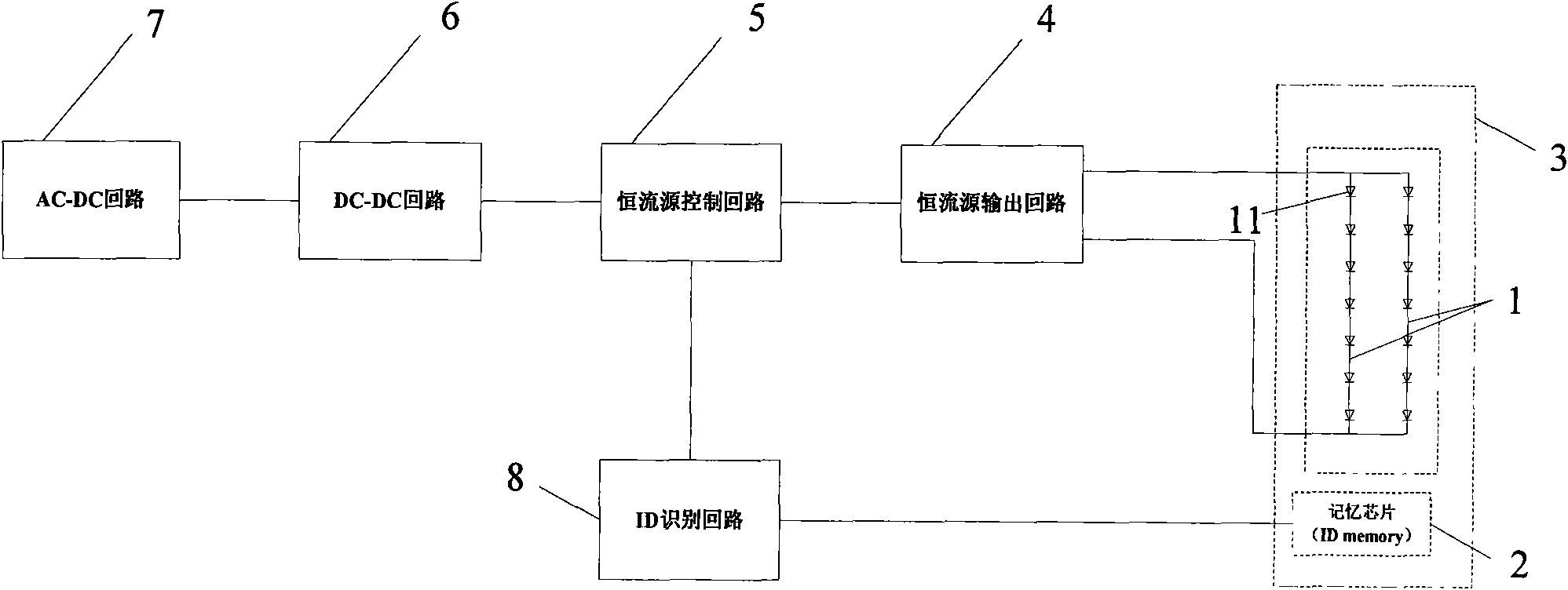

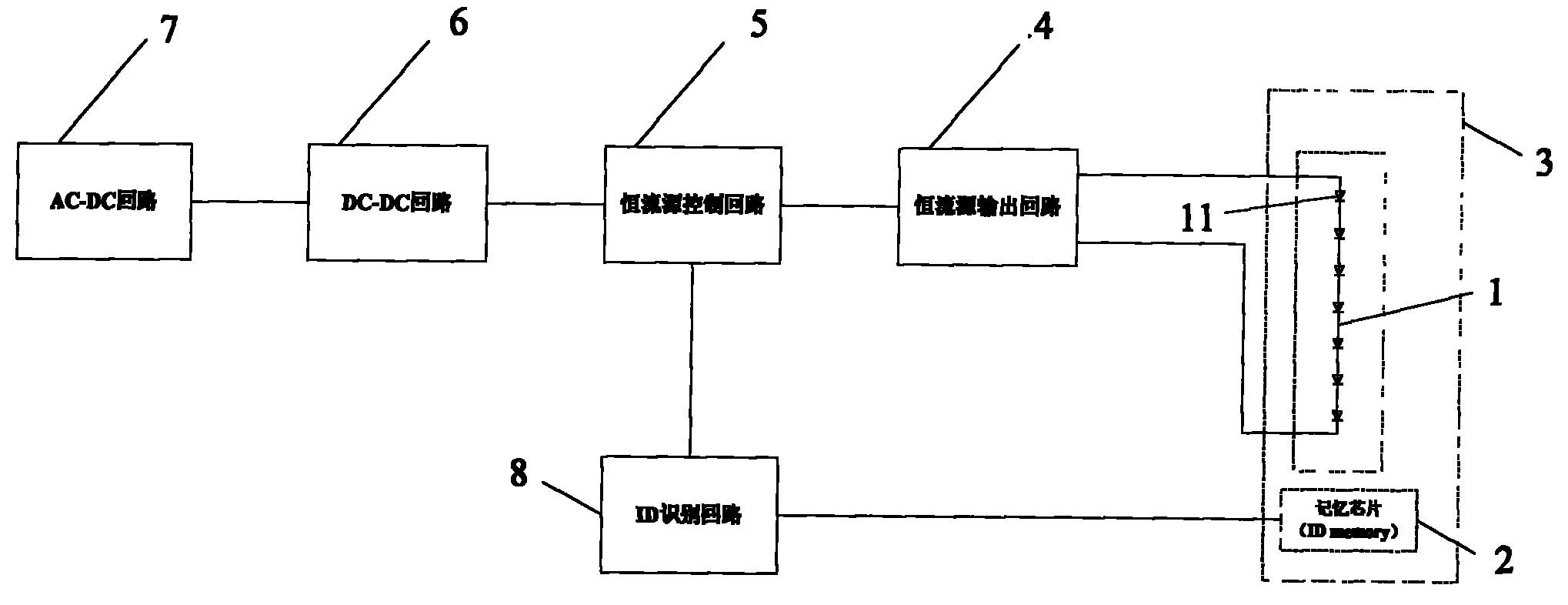

[0024]The implementation method is as follows: the AC-DC circuit 7 of the power supply part converts the public AC voltage of the city network into an available DC voltage; the DC-DC circuit 6 is a DC voltage conversion circuit, and the DC voltage output by the AC-DC circuit 7 is converted into The lower DC voltage provides working voltage for different constant current source control circuits. When one or more LED load light sources 3 are connected to the power supply, the ID identification circuit 8 reads the stored information of the memory chip (ID memory module) 2 in the LED load light source 3, and calculates the constant current according to the connection of the LED load light source 3 The output rating of the source is fed back to the constant current source control loop 5. The constant current source control circuit 5 controls the current output range of the constant current source output circuit 4 (continuously adjustable within 0-rated value) according to the feedb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com