Numerically controlled universal flange machine

A flange machine, universal technology, applied in the field of CNC universal flange machine, can solve the problems of affecting work efficiency, plate cannot be processed, time-consuming and labor-intensive, etc., to achieve improved work efficiency, good fixing effect, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

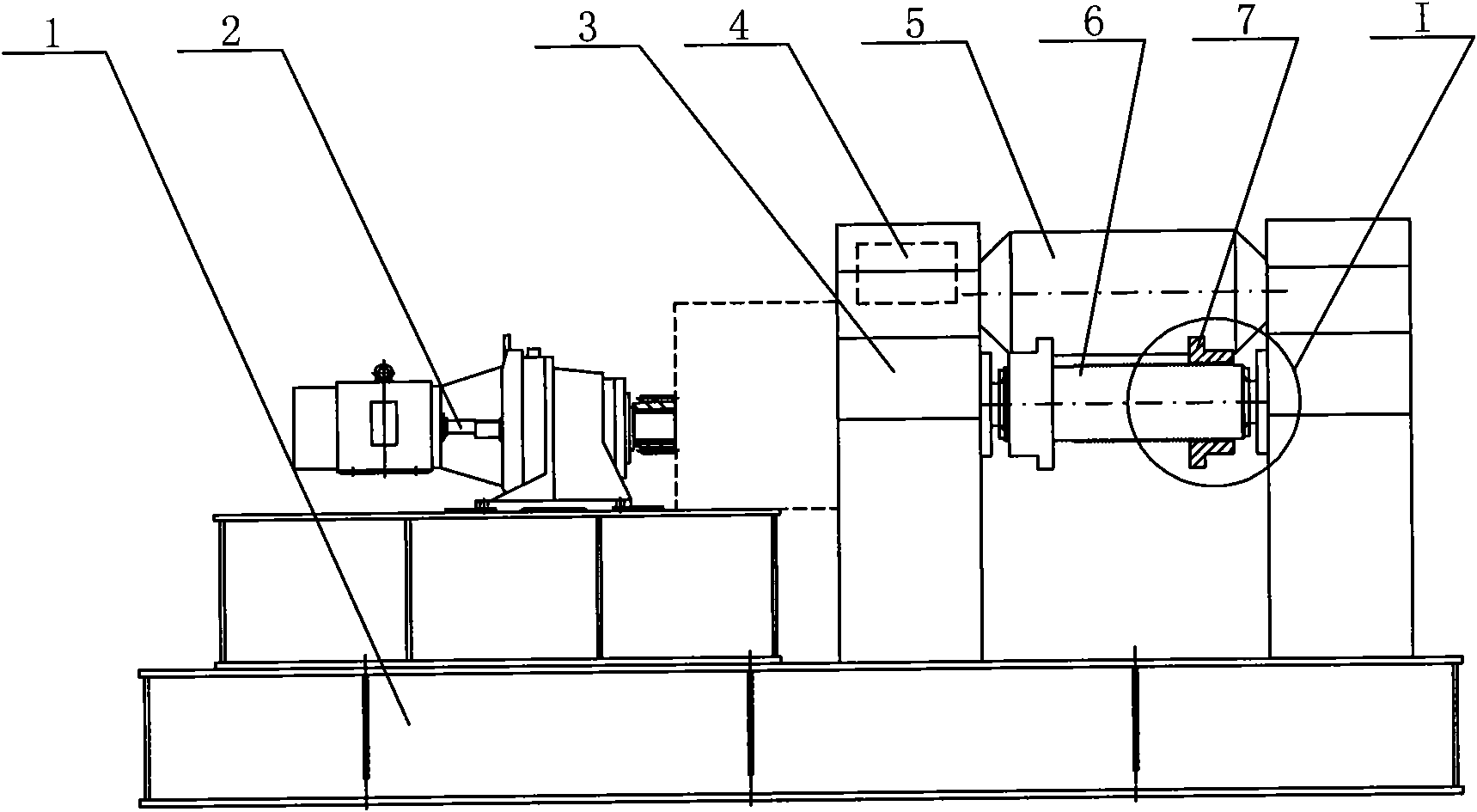

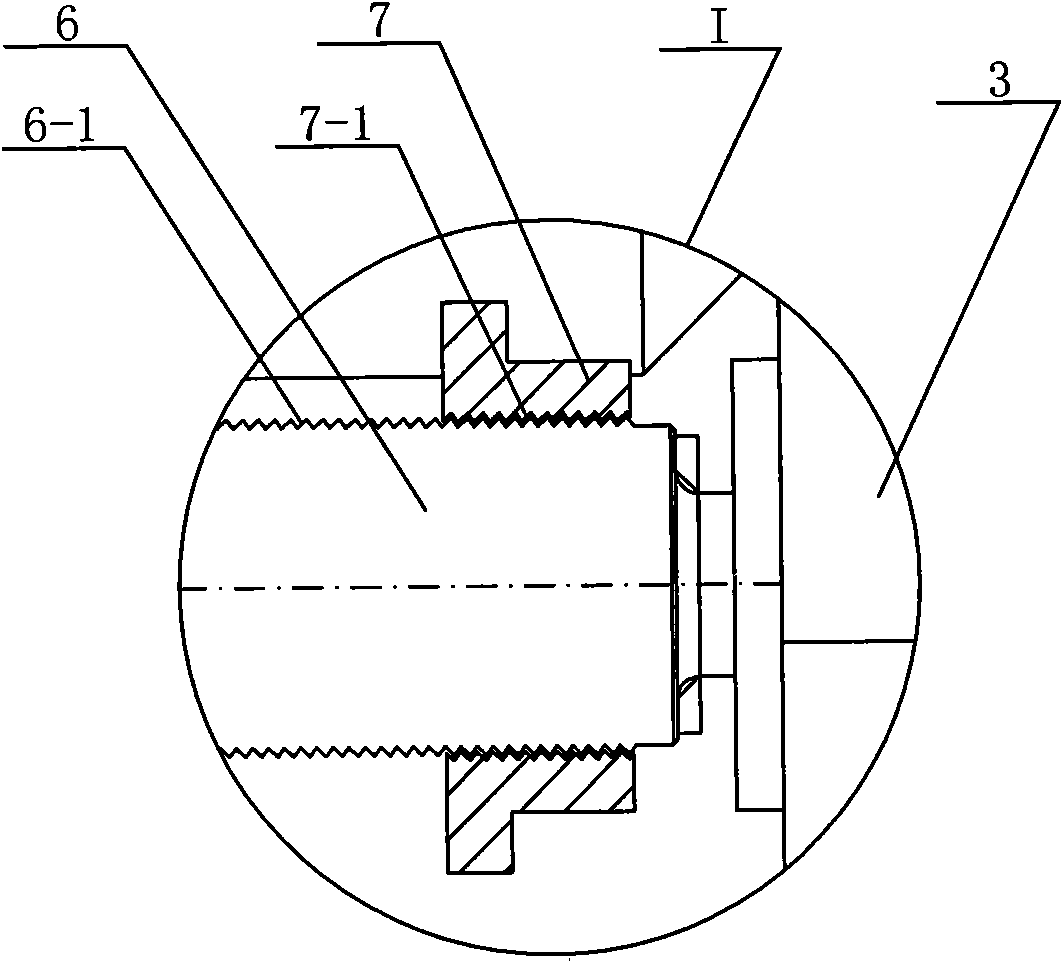

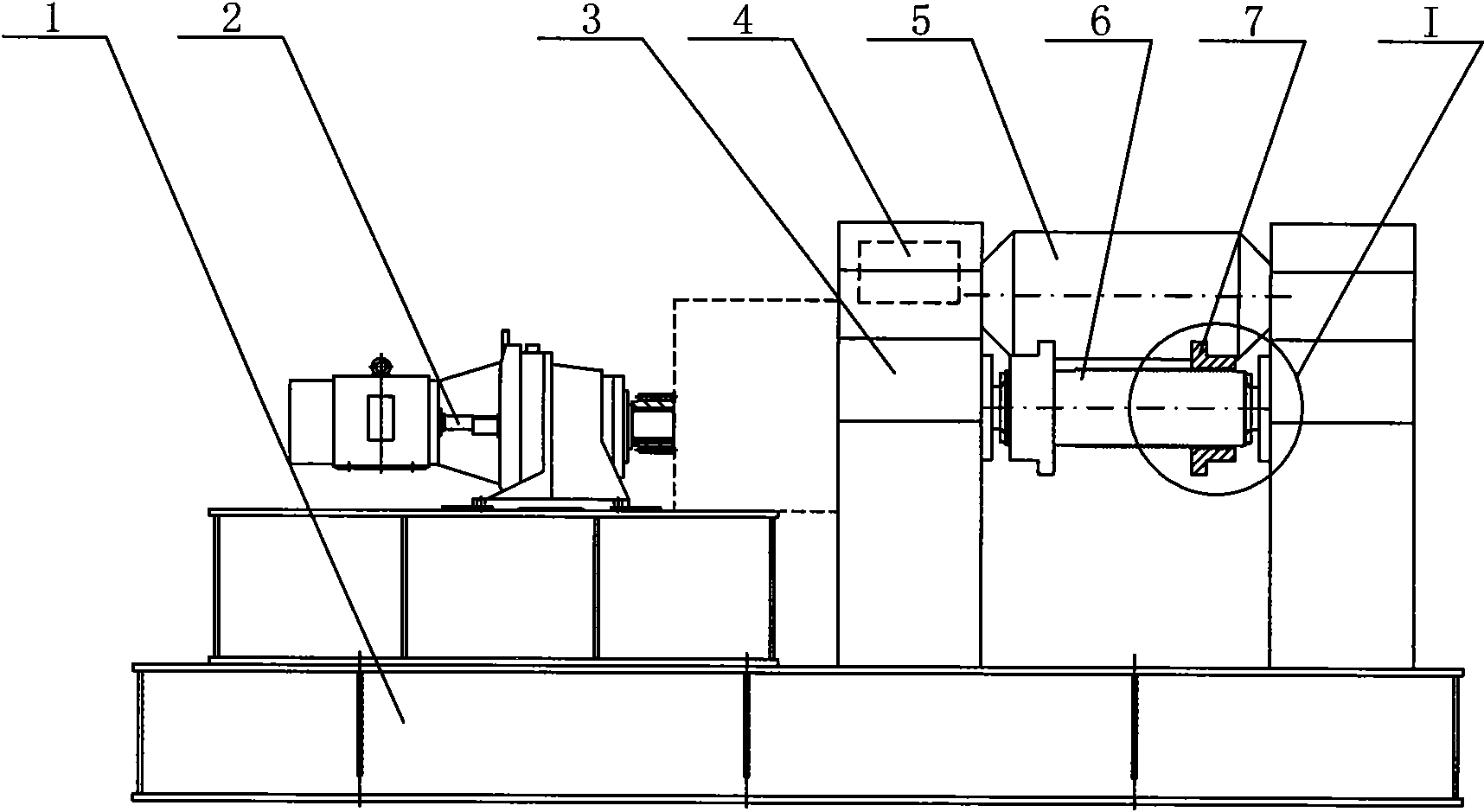

[0011] refer to Figure 1-2 , the specific embodiment adopts the following technical scheme: it comprises base 1, motor 2, frame 3, speed reducer 4, upper roller 5 and lower roller 6, upper roller and 5 lower rollers 6 are arranged between two frames 3, Speed reducer 4 is connected with upper roller 5, and motor 2 and frame 3 are arranged on the base 1, and it also includes mold 7, and mold 7 is arranged on the outside of lower roller 6.

[0012] The outside of the lower roller 6 is provided with an external thread 6-1.

[0013] The mold 7 is divided into two parts, one part is fixed on the left end of the lower roller 6, and the other part is provided with an internal thread 7-1 matched with the external thread 6-1.

[0014] When in use, the mold 7 can be adjusted to adapt to different plate thicknesses. It is easy to use and has a good fixing effect. The plate is not easy to move and skew. The upper roller 5 can move in parallel under the action of the motor 2 and the red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com