Pull-type follow-up bearing device of long lead screw of machine tool

A technology of supporting device and long lead screw, which is applied to feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of unsuitable precision grinding processing equipment, affecting the quality of the processed surface, and limited supporting rigidity, etc. The effect of machining accuracy and surface quality, maintaining motion stability, and improving motion rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

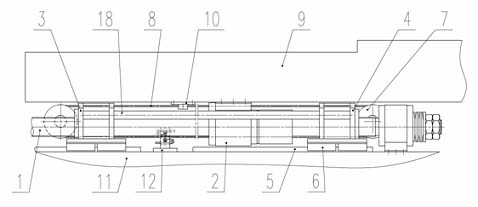

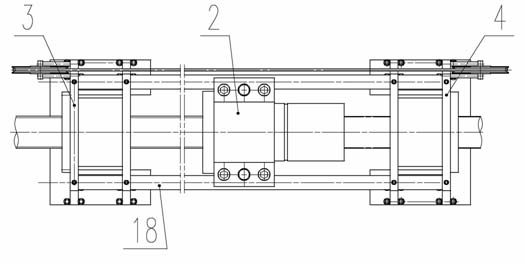

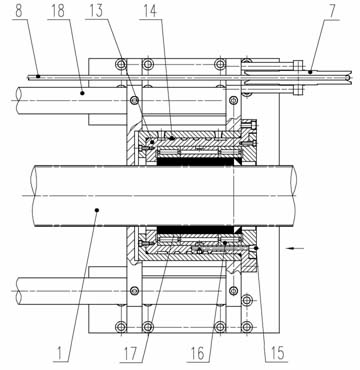

[0017] Example: such as figure 1 , figure 2 As shown, the diameter of the lead screw 1 is 80 mm, the length is 7597 mm (model: 8040-7597-7022-IT5), the nut seat 2 is a HT250 casting, connected with the worktable 9 by screws, and cooperates with the lead screw 1 to form a lead screw transmission pair. There is left follow-up support 4 on the left side of nut seat 2, and right follow-up support 5 is arranged on the right, all are weldment assembly components, also can be integral castings. Traction pulley 7 is housed on the right side of left follow-up support 3, and traction pulley 7 is housed on the left side of right follow-up support 4. Two traction pulleys 7 can rotate around their own axes, and a wire rope 8 with a diameter of 6 mm is set between the two pulleys. One end of the wire rope 8 is fixed on the pressing block 10 of the workbench 9, and the other end is fixed on the pressing block of the bed 11. On the seat 12, the briquetting block 10 and the pressing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com