Mixed base bar code printing ribbon and preparation method thereof

A barcode printing, mixed-based technology, applied in printing, ink ribbon, inking device and other directions, to achieve the effect of simple preparation method, overcoming the narrow adaptability of wax-based printing materials, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

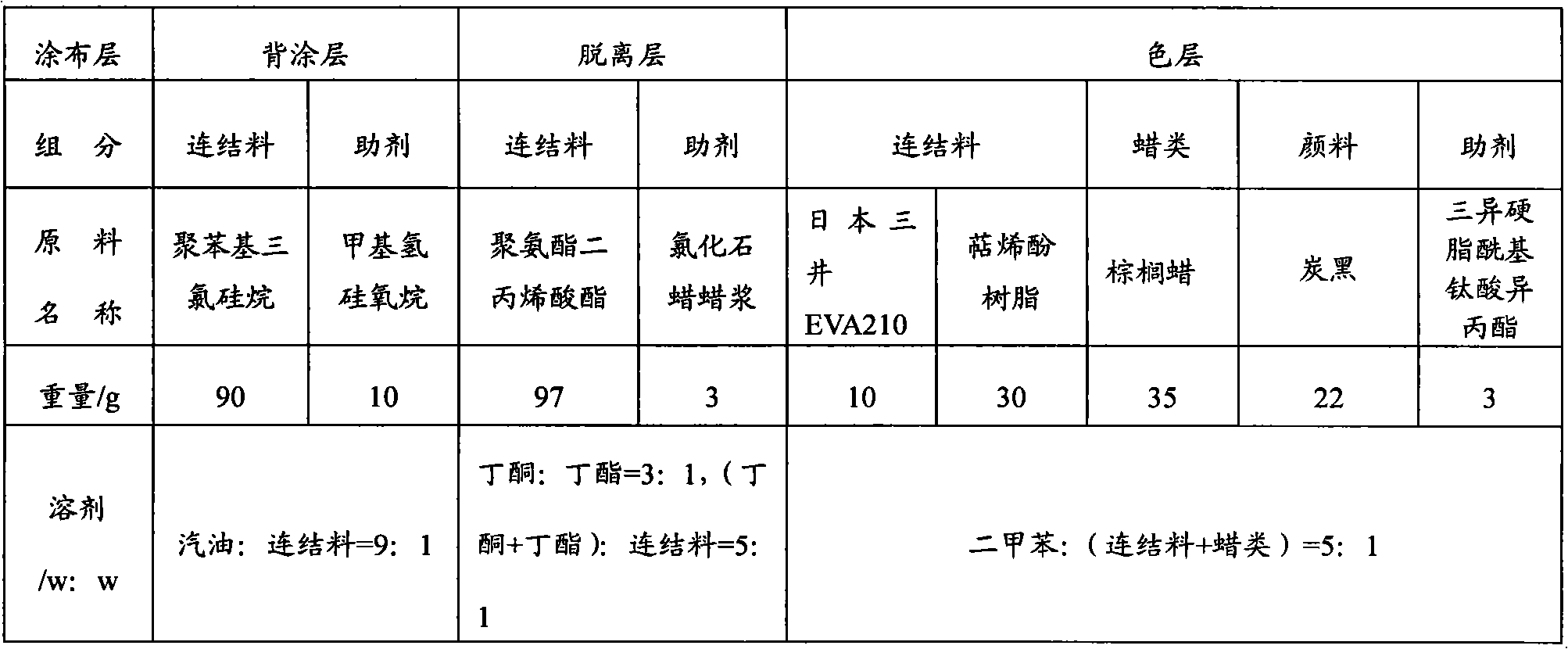

Embodiment 1

[0036]

[0037] Preparation:

[0038] a. Dilute and mix the binder of the back coating with gasoline, then add additives in proportion and mix evenly within 30 minutes before use, coat the surface of one side of the tape base with a thickness of 4 μm, and dry at 80°C to form The back coating with a thickness of 0.2 μm enters the next process;

[0039] b. Use a mixed solvent composed of methyl ethyl ketone and butyl ester to dissolve the linking material of the separation layer, then add additives in proportion to mix evenly, coat the surface on the other side of the tape base, and dry at 80°C to form a 2μm thick film The detachment layer enters the next process;

[0040] c. Dissolve the linking material and wax with xylene, then add pigments and additives in proportion, grind until the fineness of the pigment is less than 3μm, excluding 0μm, apply it on the outside of the release layer after grinding, and dry it at 80°C A color layer with a thickness of 3 μm is formed to ...

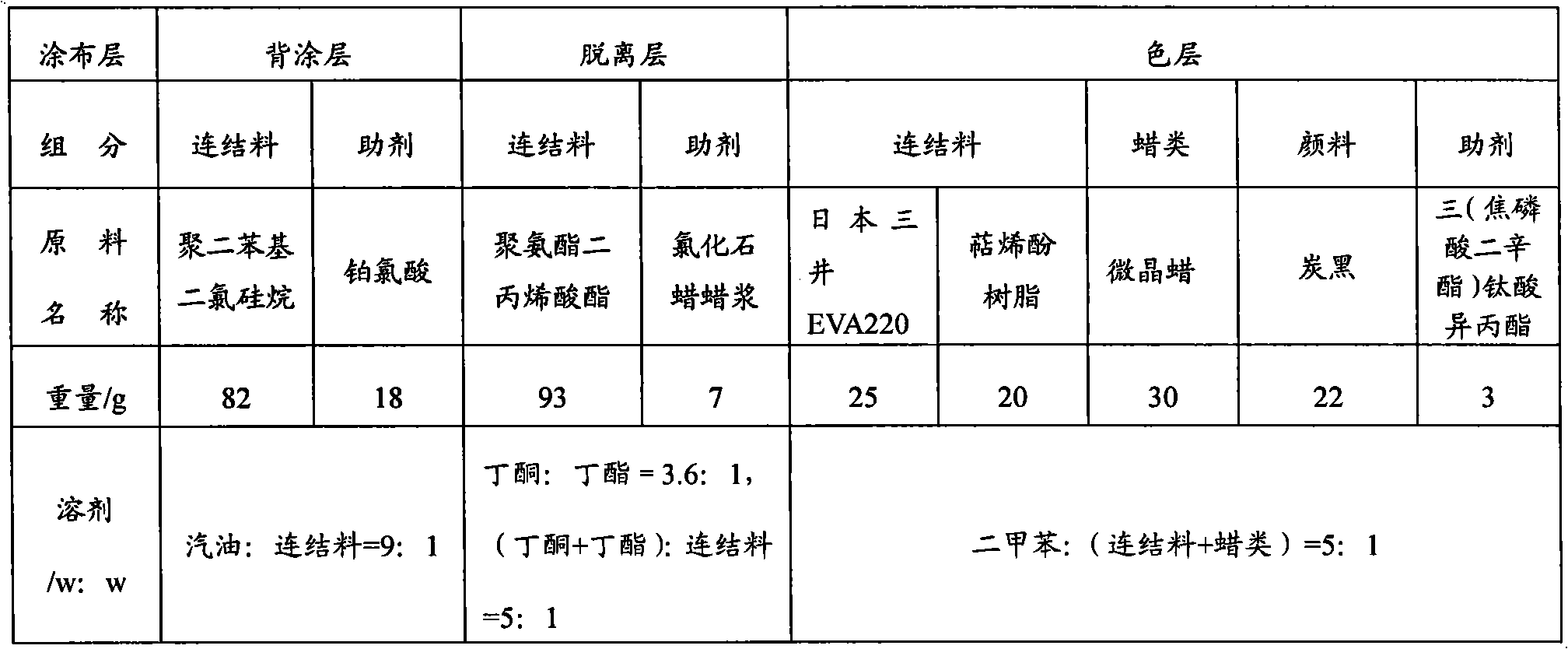

Embodiment 2

[0042]

[0043] Preparation:

[0044]In step a, the base thickness is 4.3 μm, the drying temperature is 83°C, and the thickness of the back coating is 0.5 μm; in step b, the drying temperature is 85°C, and the thickness of the release layer is 2 μm; in step c, the drying temperature is 80°C, The thickness is 2 μm; the total thickness of the mixed-base barcode printing ribbon is 8.8 μm; the others are the same as in Embodiment 1.

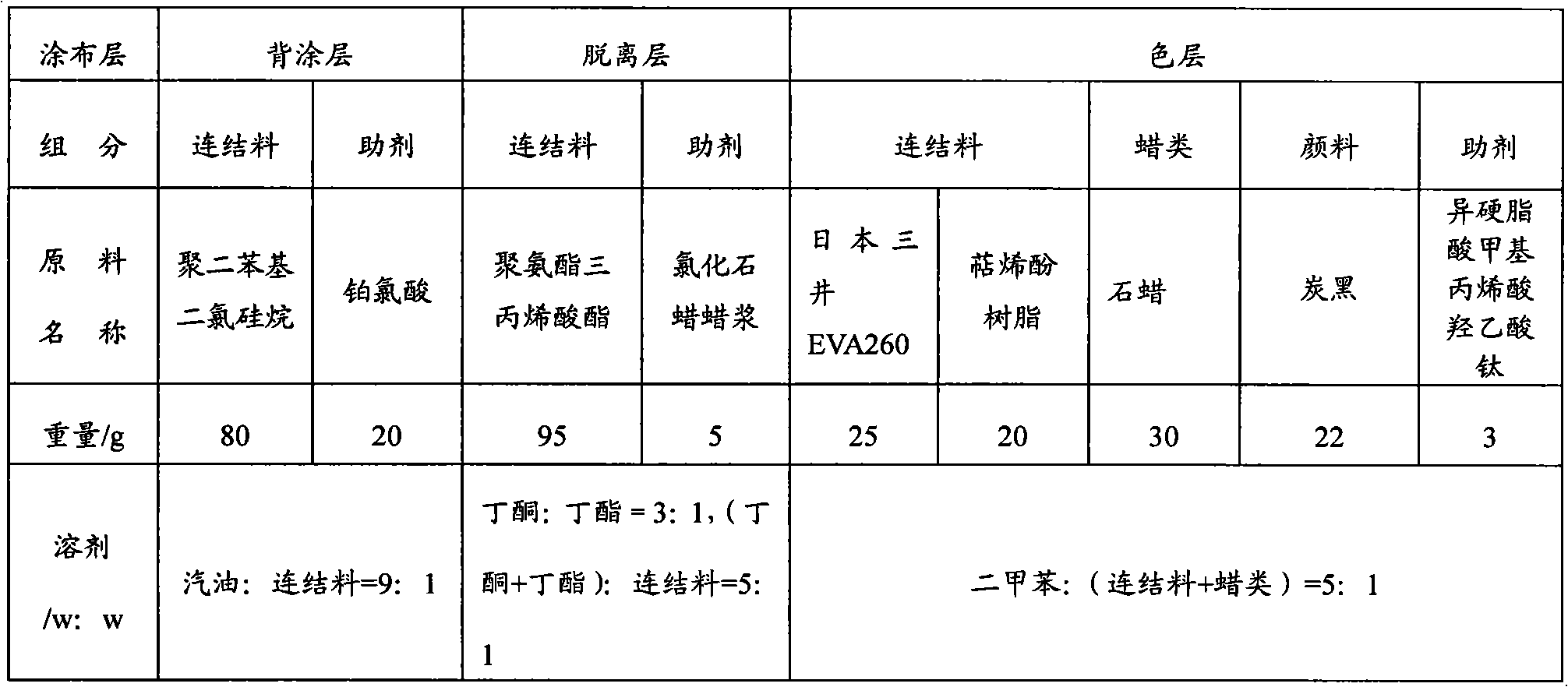

Embodiment 3

[0046]

[0047] Preparation:

[0048] In step a, the base thickness is 4 μm, the drying temperature is 85°C, and the back coating thickness is 0.2 μm; in step b, the drying temperature is 90°C, and the release layer thickness is 1 μm; in step c, the drying temperature is 100°C, and the color layer thickness 1.5 μm; the total thickness of the mixed base barcode printing ribbon is 6.7 μm; the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com