Rotor configuration for a rotary valve

A rotary valve and rotor technology, applied in the valve device, valve details, valve shell structure, etc., can solve the problems of reducing the overall volume of the rotary valve, reducing the operating volume and size of the rotary valve, and improving the anti-air leakage capability, enhancing the The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

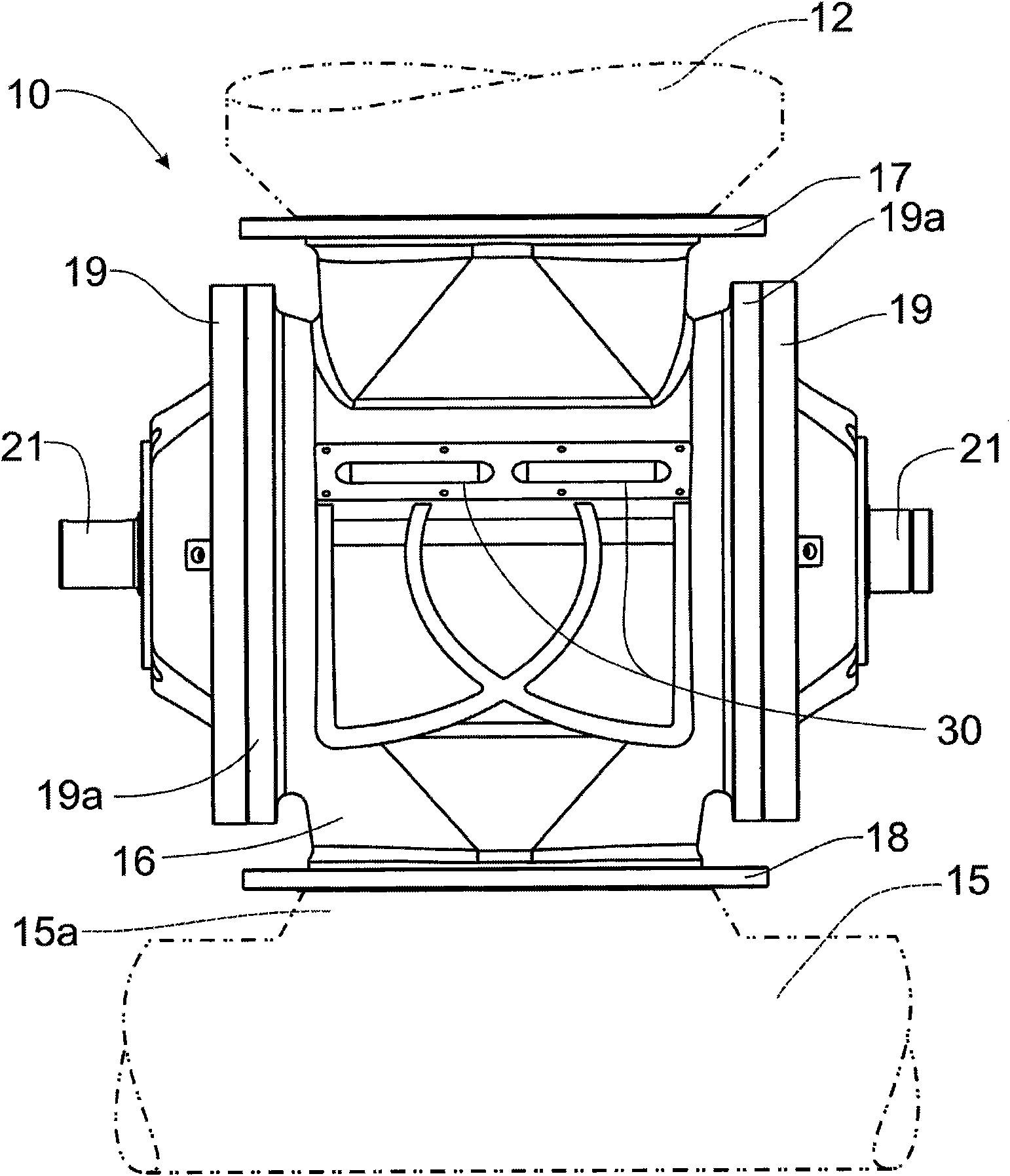

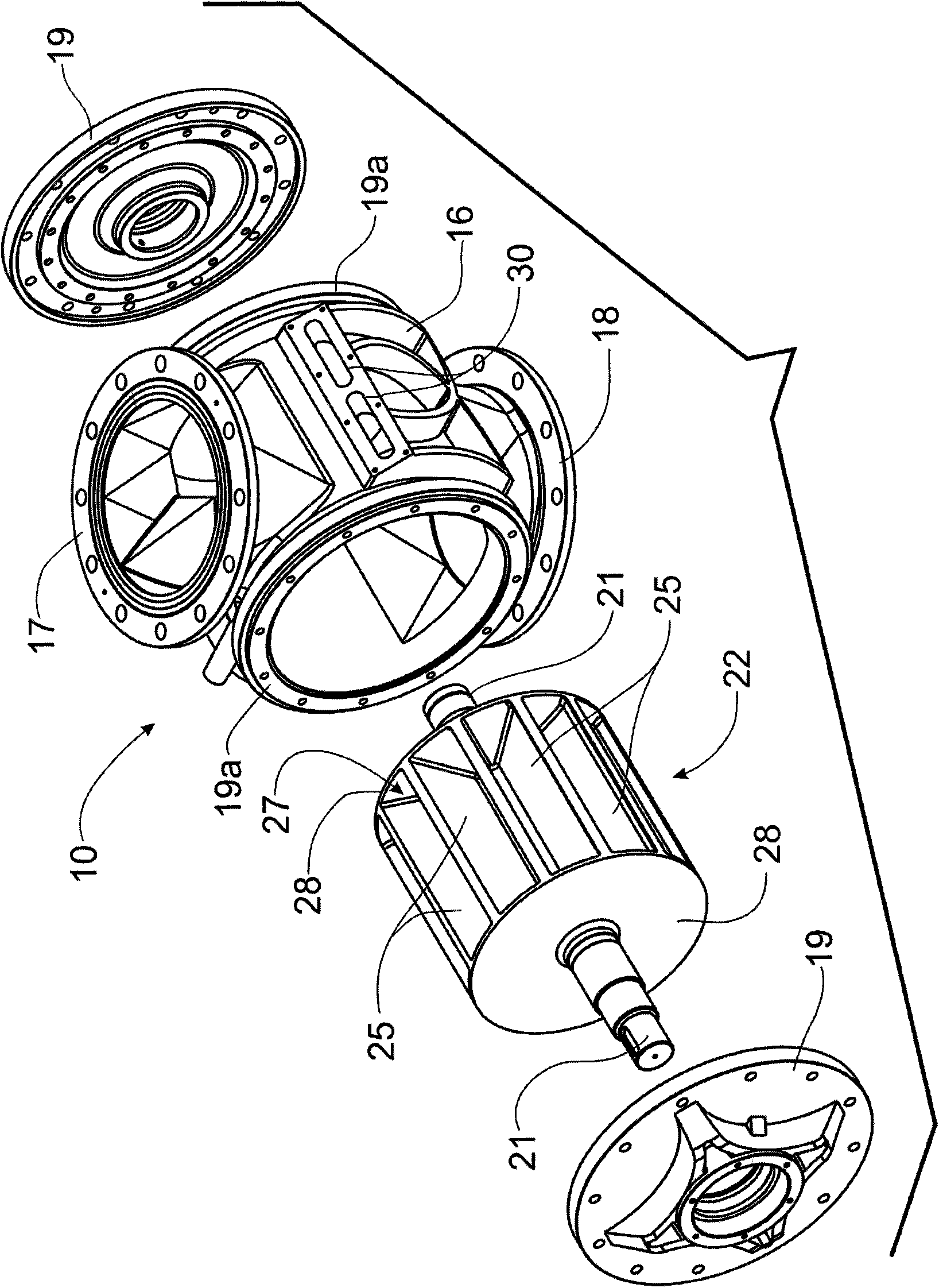

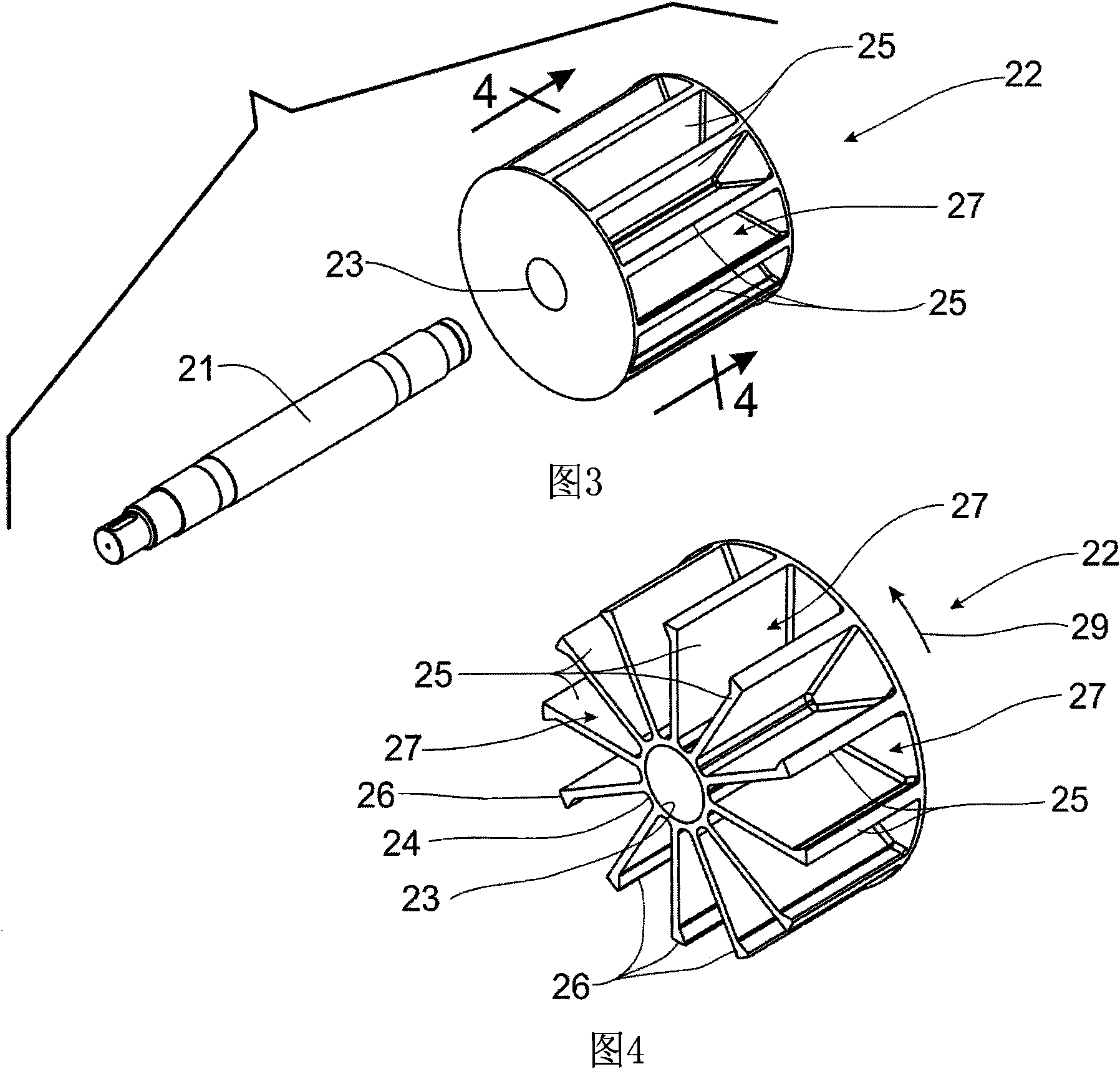

[0032] refer to figure 1 and 2 , which shows a rotary valve in accordance with the principles of the invention. A rotary valve 10 is operatively located between a supply hopper 12 which supplies granular material, such as plastic pellets, etc., which is injected into the conduit 15 of the pneumatic conveying system so that the particles are transported by the pneumatic conveying system Material moves to a distant location. The purpose of the rotary valve is to convey the flowing particulate material into conduit 15 in such a manner that compressed air within the pneumatic conveying system remains within the conduit, thereby providing fluidized particulate material to a remote location. The rotary valve 10 accomplishes this function by operation of an inner rotor assembly 20 having radially extending vanes 25 defining a chamber or pocket 27 therebetween, thereby containing granular material from the supply hopper 12 , and move the particulate material to conduit 15. The end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com