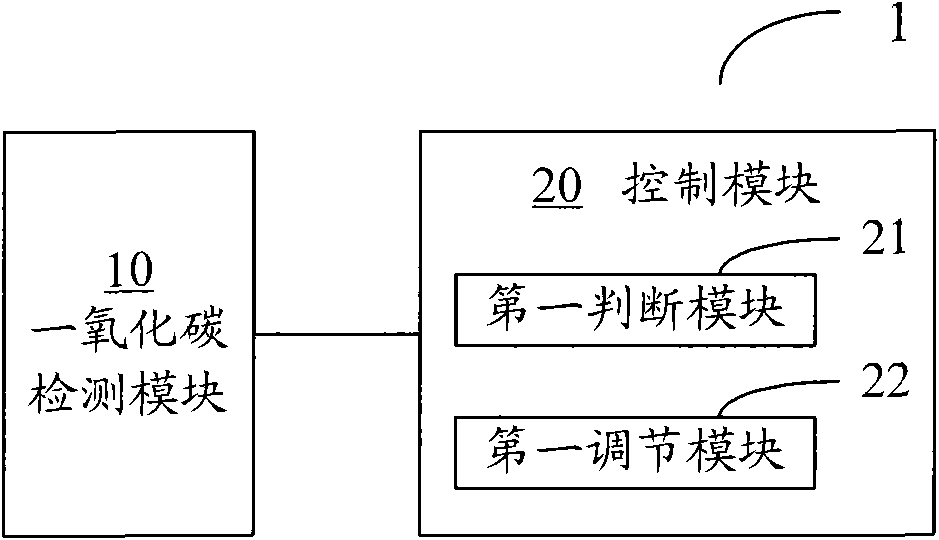

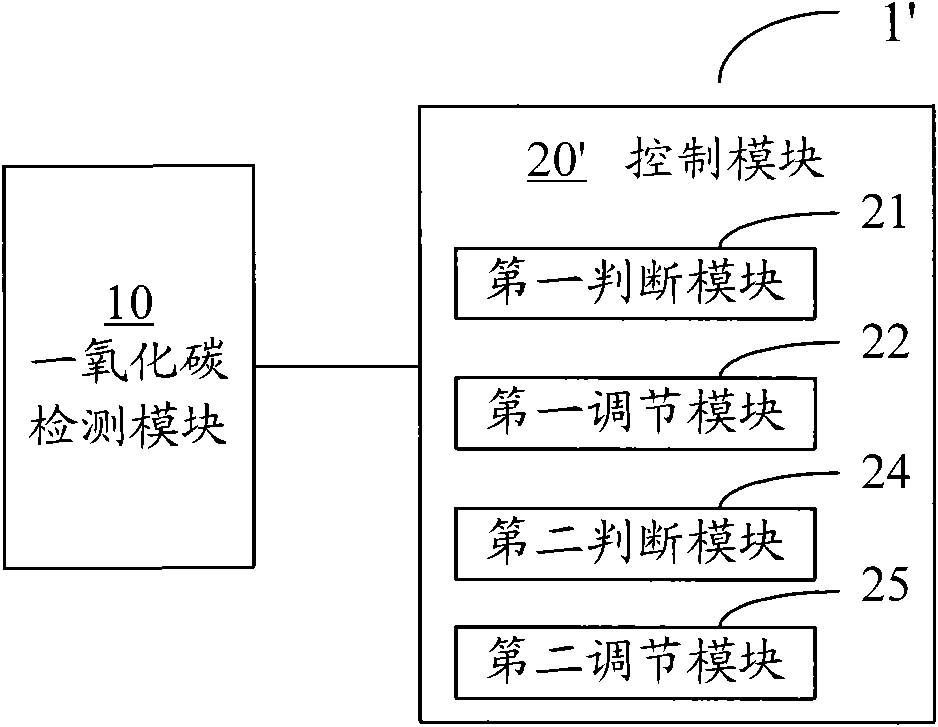

Control system and method of baking furnace

A control system and control method technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of increased energy consumption, unrealizable, high tar content, etc., to improve combustion efficiency, ensure product quality, and reduce pollutants. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

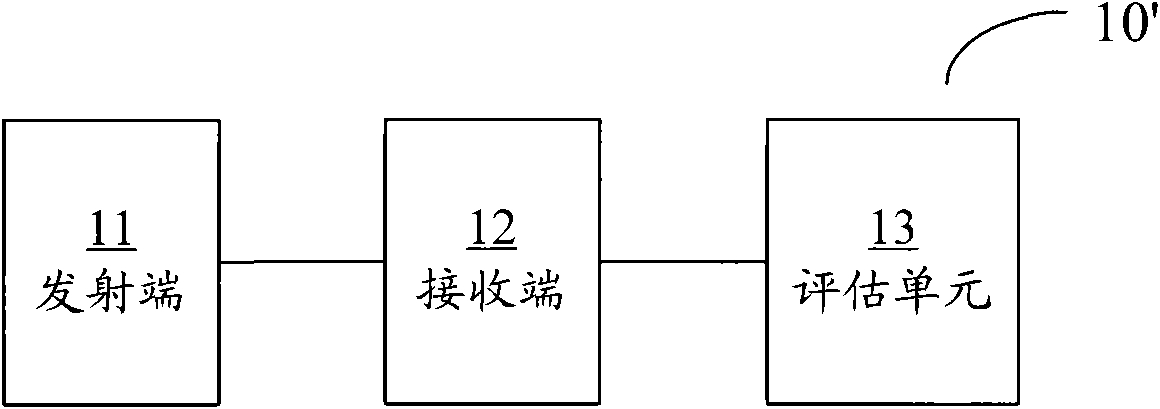

Embodiment Construction

[0019] For the purpose of description, a conventional roaster is briefly introduced first. As we all know, a roasting furnace (for example, an anode roasting furnace) can include a plurality of furnace chambers, and each furnace chamber can be provided with a plurality of fire passages, wherein, the number of furnace chambers and fire passages can be designed according to capacity requirements, and the number of furnace chambers is generally 18 to 54, the number of fire channels is generally 7 to 10. The exhaust gas generated by combustion in multiple fire channels is discharged into the collection flue through the flexible connection pipe of the smoke exhaust rack of the roaster, and finally discharged into the atmosphere after purification. The combustion device of the roaster is one of the main components of the roaster, which may include a burner that enables the fuel to burn, fuel control equipment, air intake equipment, and exhaust equipment. It can be understood that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com