Bond strength testing method of concrete rough aggregate interface

A technology of strength testing and interfacial bonding, which is used in the application of repetitive force/pulsation force to test the strength of materials, the application of stable tension/pressure to test the strength of materials, and the measurement device. It can solve the problems of complicated operation, inaccurate test results, Coarse-aggregate interface differences and other problems, to achieve accurate and stable test results and real loading environment, the effect of good loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

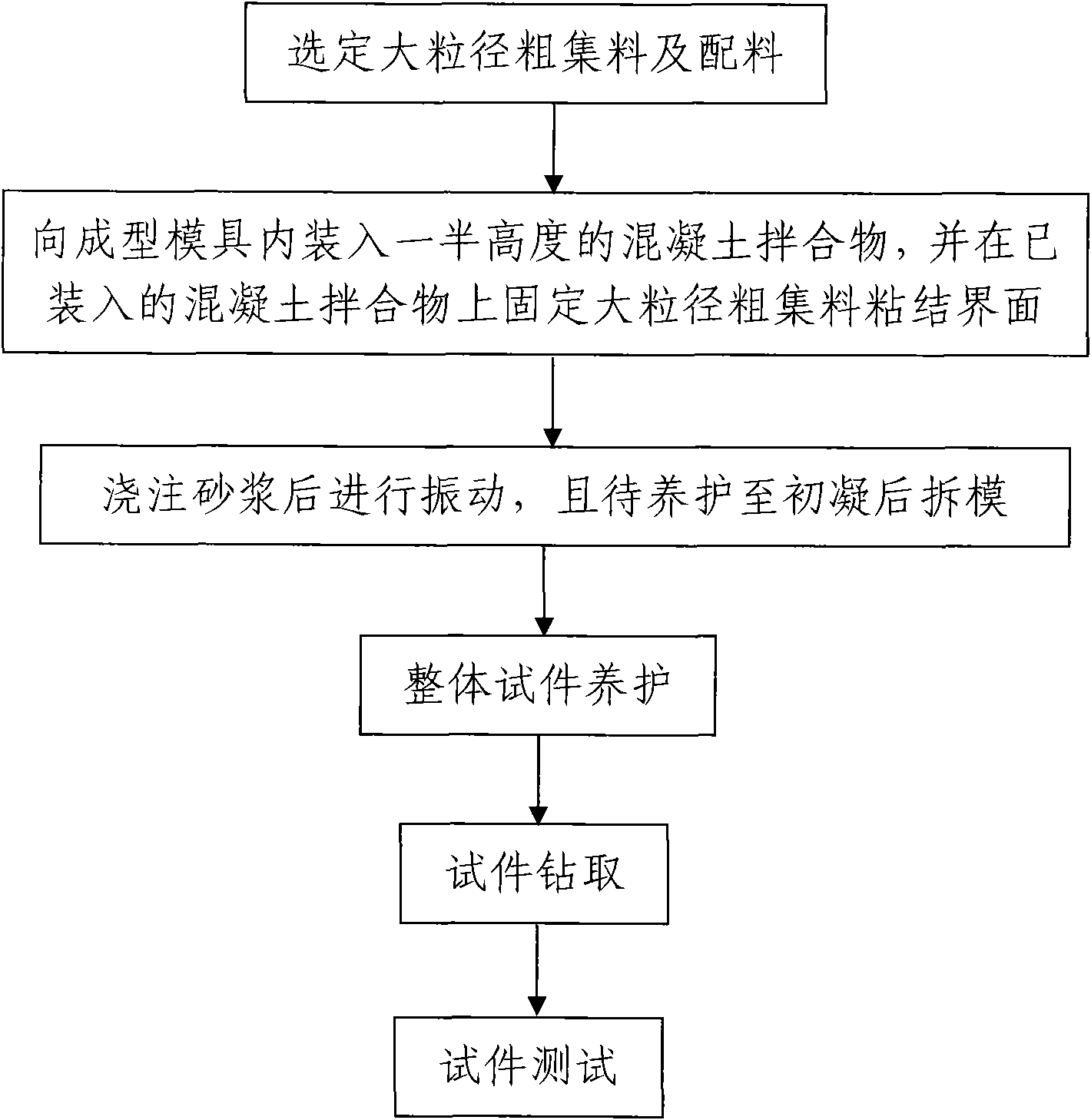

[0042] Such as figure 1 A kind of concrete coarse aggregate interfacial bond strength testing method shown, comprises the following steps:

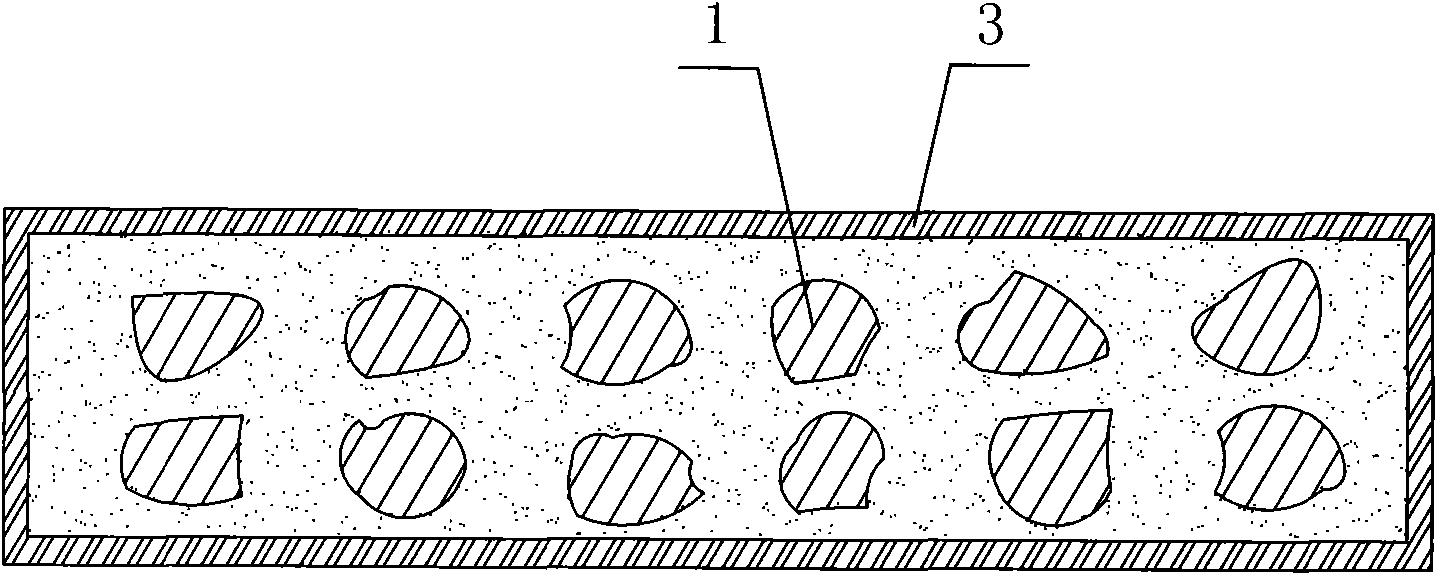

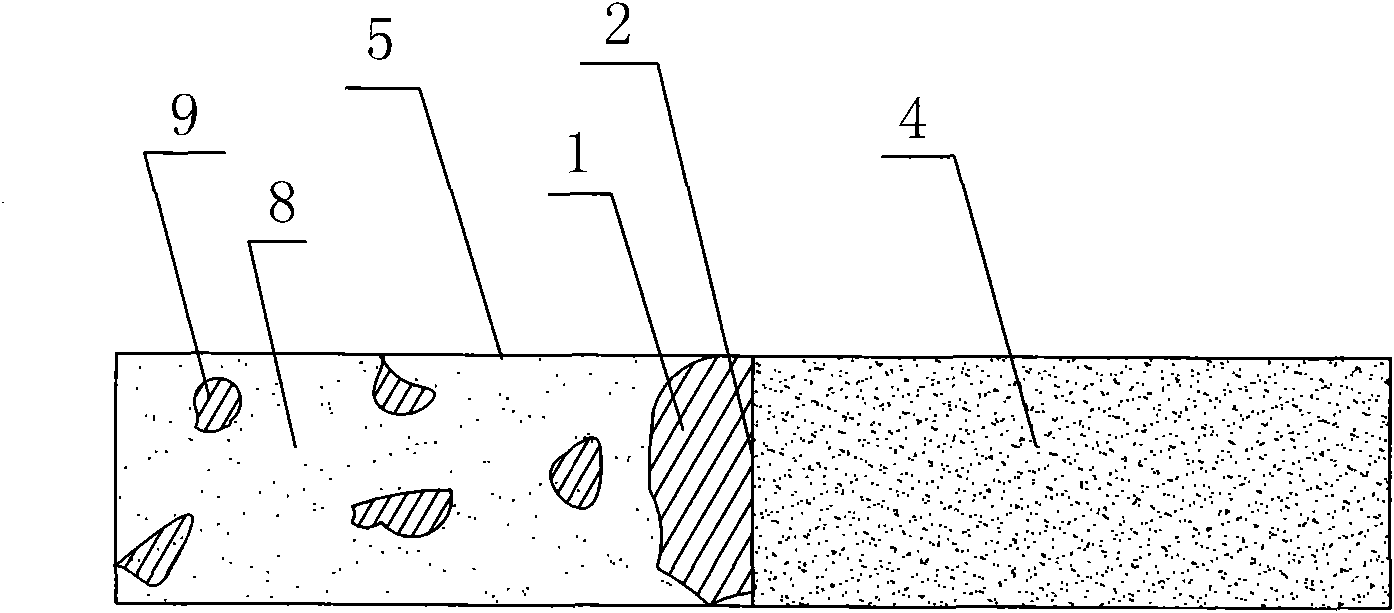

[0043] Step 1. Select large particle size coarse aggregate and batching: weigh and batch according to the mixing ratio between the components in the concrete to be tested, and use it to prepare the coarse aggregate particle size of the concrete to be tested ≤ 30mm, before batching First select the coarse aggregate 1 with a particle size of 25 mm to 30 mm and a plane side surface from the weighed coarse aggregate, and then use the weighed aggregate to prepare the concrete to be tested. The components are stirred and mixed evenly to form a concrete mixture; the plane is the bonding interface 2 of the coarse aggregate 1 with large particle size.

[0044] When actually selecting the coarse aggregate 1 with a large particle size, the plane is an outer surface close to the plane in the coarse aggregate 1 with a large particle size selected.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com