Broken-line etching design method of soft printed circuit board electroplating lead

A technology for printed circuit boards and electroplating leads, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as metal wire residues and hidden dangers of short circuits, and achieve the effect of eliminating hidden dangers of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

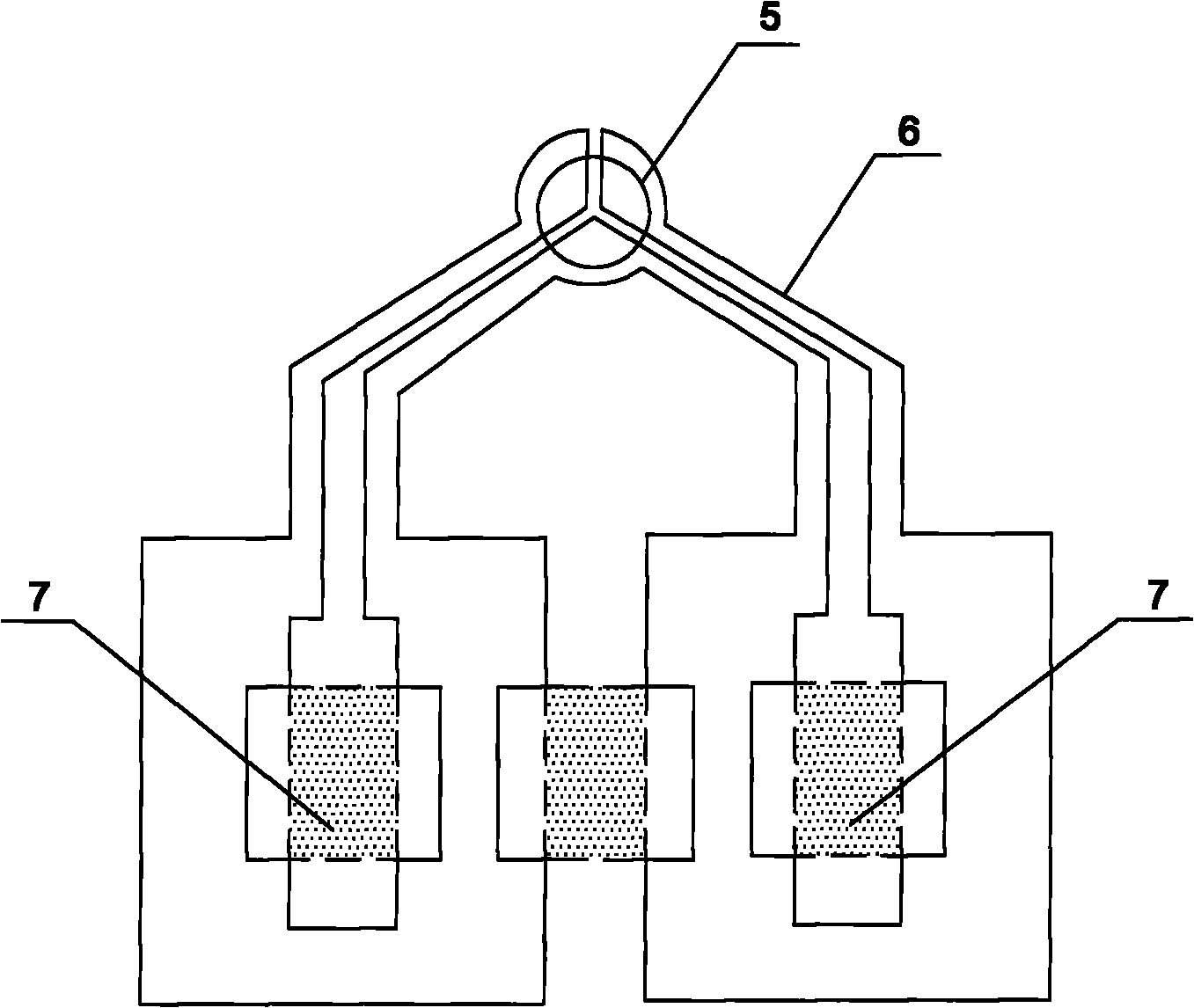

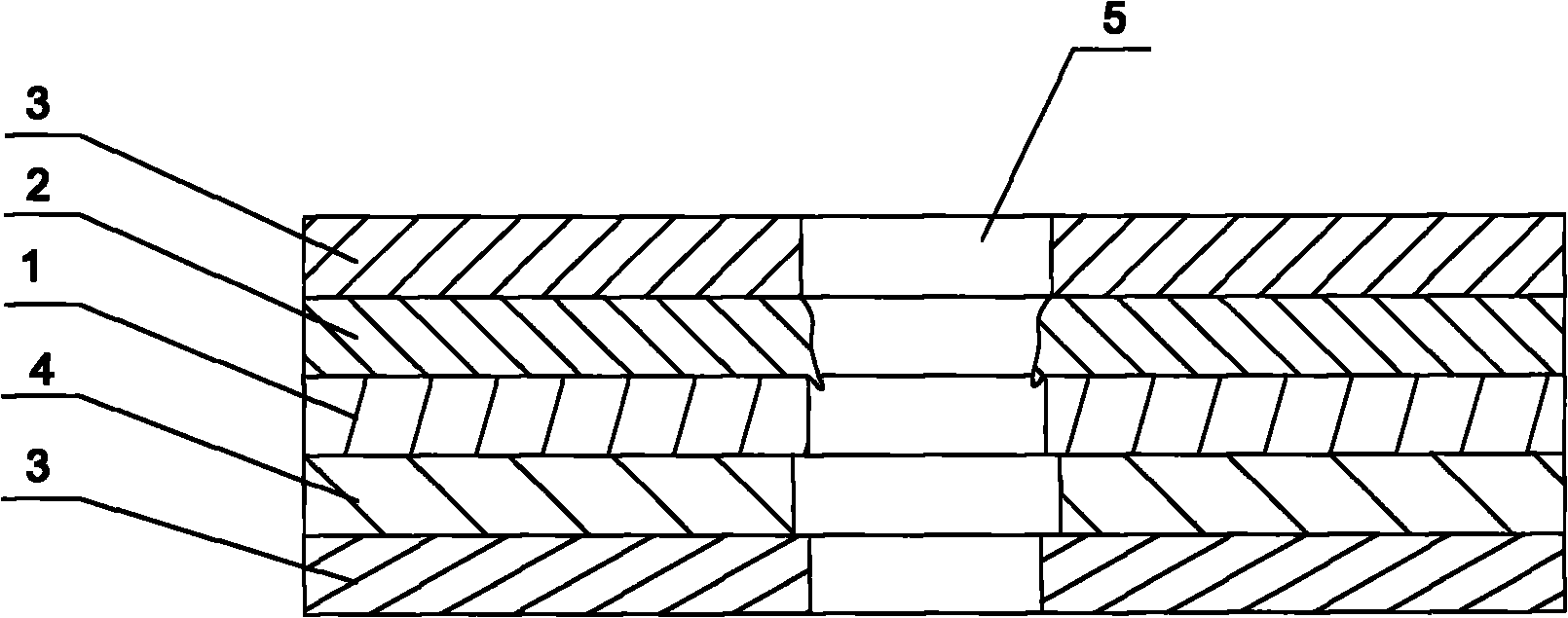

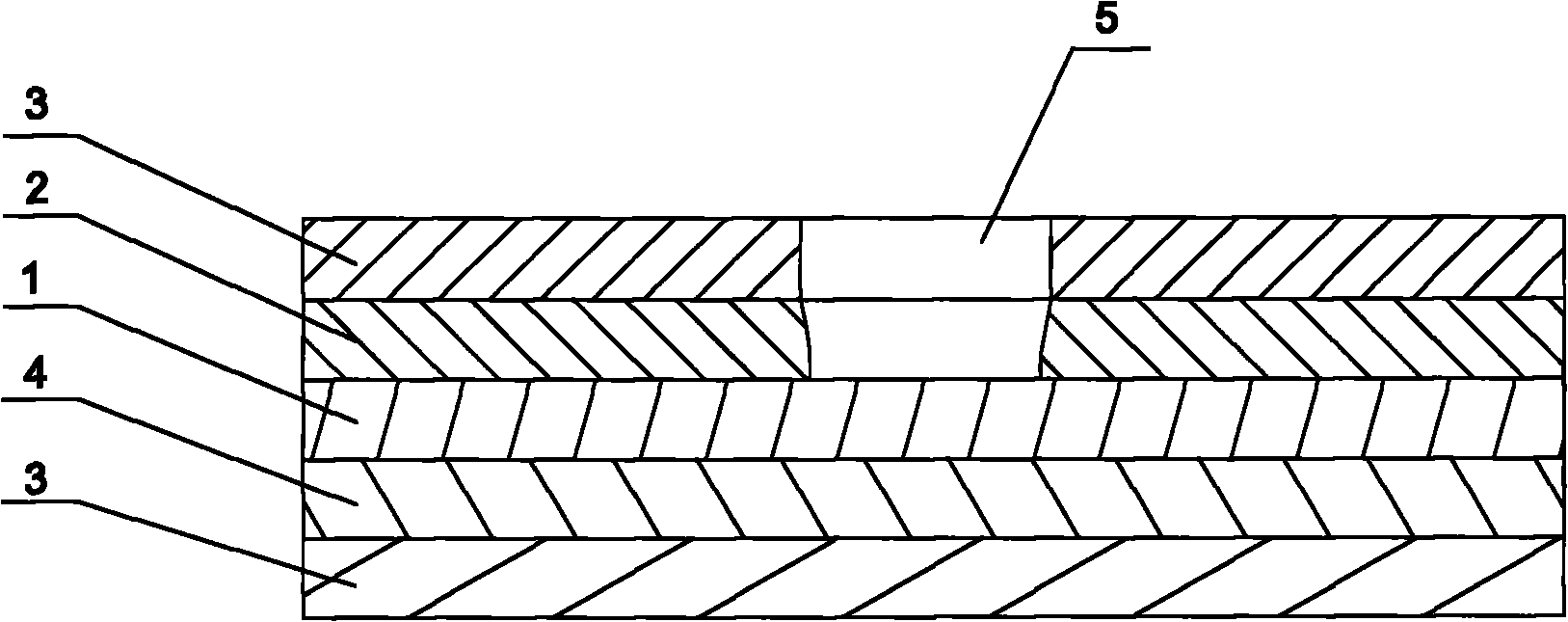

[0020] See attached figure 1 And attached figure 2 . The circuit board includes a substrate 1 including a first surface and a second surface, a circuit layer 2 covering the first surface of the substrate 1, a solder resist layer 3 covering the circuit layer 2, and a circuit layer covering the substrate 1. The back circuit layer 4 on the second surface, and the solder resist layer 3 covering the back circuit layer 4 . During electroplating, the electroplating leads 6 are drawn out from the circuit layer 2 to deposit nickel and gold on the surface of the electroplating plate 7. After electroplating, the electroplating leads 6 need to be disconnected.

[0021] When using the original method to disconnect the electroplating lead 6, punch a hole at the position of the disconnection hole 5, the position of the back circuit layer 4 corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com