Centring gesture correcting member of full-position welding robot

A welding robot and all-position technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as large coupling, cumbersome algorithms, and complex structures, and achieve coupling elimination, simplified algorithms, and simple adjustments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Attached below Figure 1 ~ Figure 4 A preferred embodiment of the present invention will be described in detail.

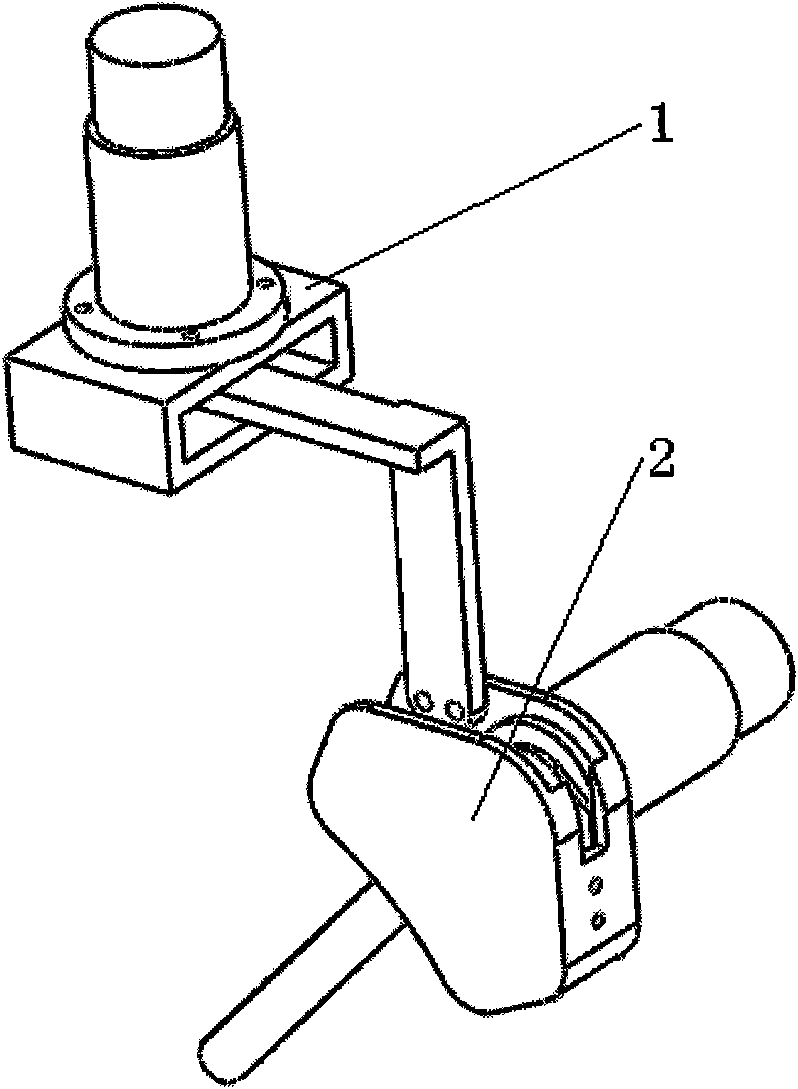

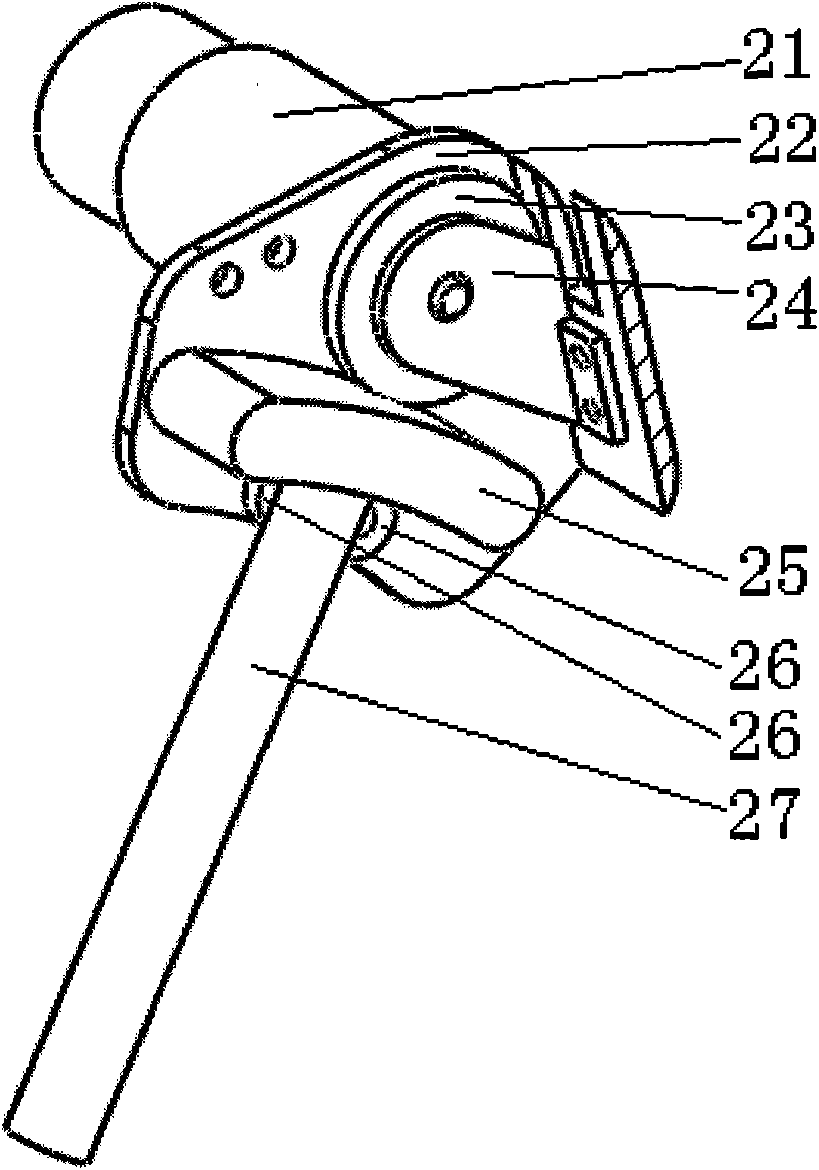

[0018] Such as figure 1 As shown, the centering posture adjustment part of the all-position welding robot in this embodiment is composed of a horizontal angle adjustment mechanism 1 and a vertical angle adjustment mechanism 2, and is mainly used for adjusting the posture of the welding torch 27.

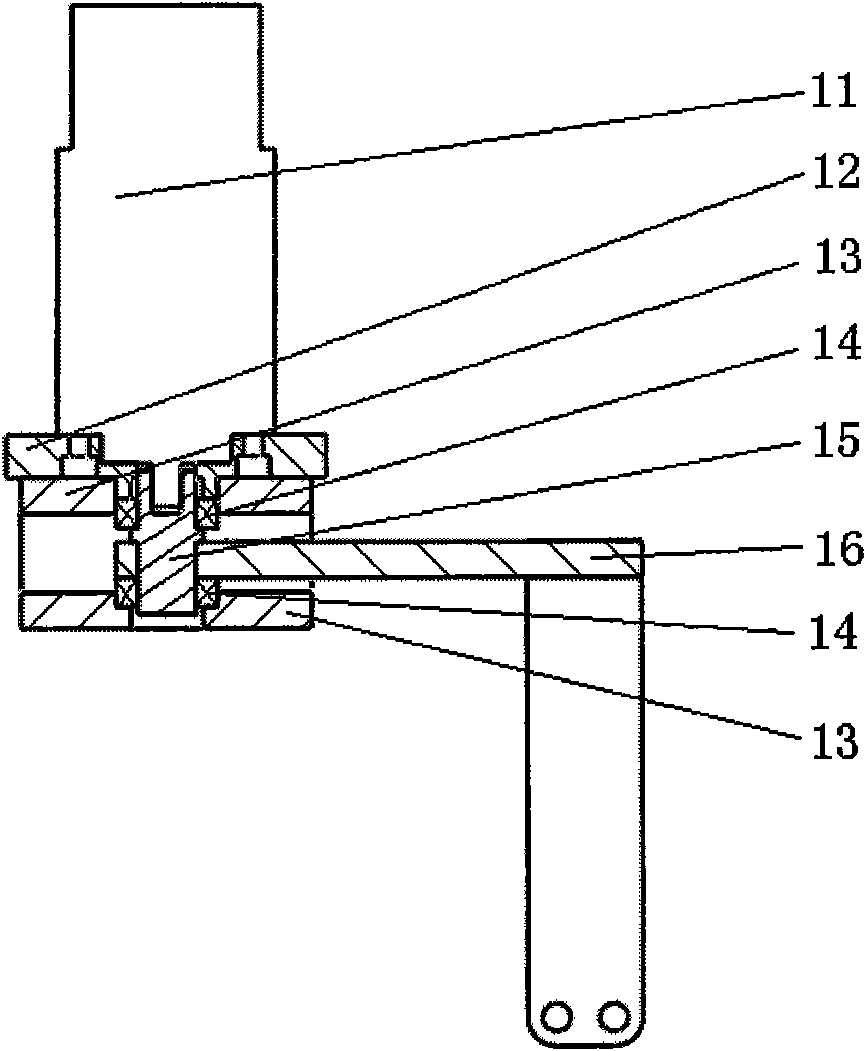

[0019] Horizontal direction angle adjustment mechanism 1 can realize horizontal direction angle adjustment, and its specific structure is as follows: figure 2 As shown, it includes a first motor 11 , an end cover 12 , a base 13 , a first bearing 14 , a transmission shaft 15 and a rocker 16 . Wherein: the base 13 is connected with the welding robot arm, the end cover 12 is fixed on the base 13 by studs, and the first motor 11 is fixed on the end cover 12 by screws. The output shaft of the first motor 11 protrudes toward the rocker 16 through the base 13, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com