Process for treating mirabilite liquid

A treatment process and technology for nitric water, applied in the directions of alkali metal sulfites/sulfites, alkali metal compounds, inorganic chemistry, etc., can solve the problems of shortened production process flow, excessive storage equipment, etc., and achieve reasonable distribution of filter holes , the effect of simple restoration and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

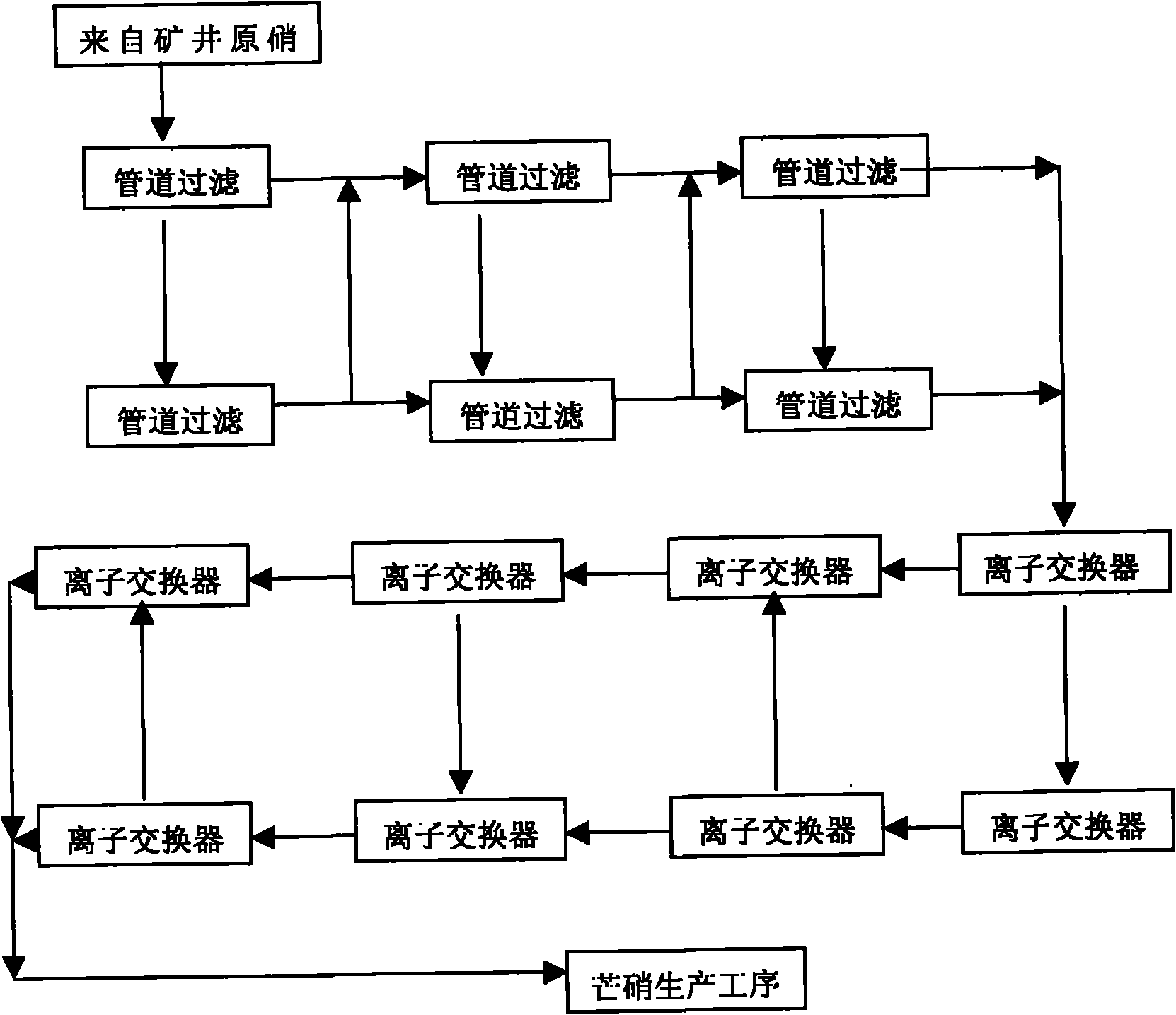

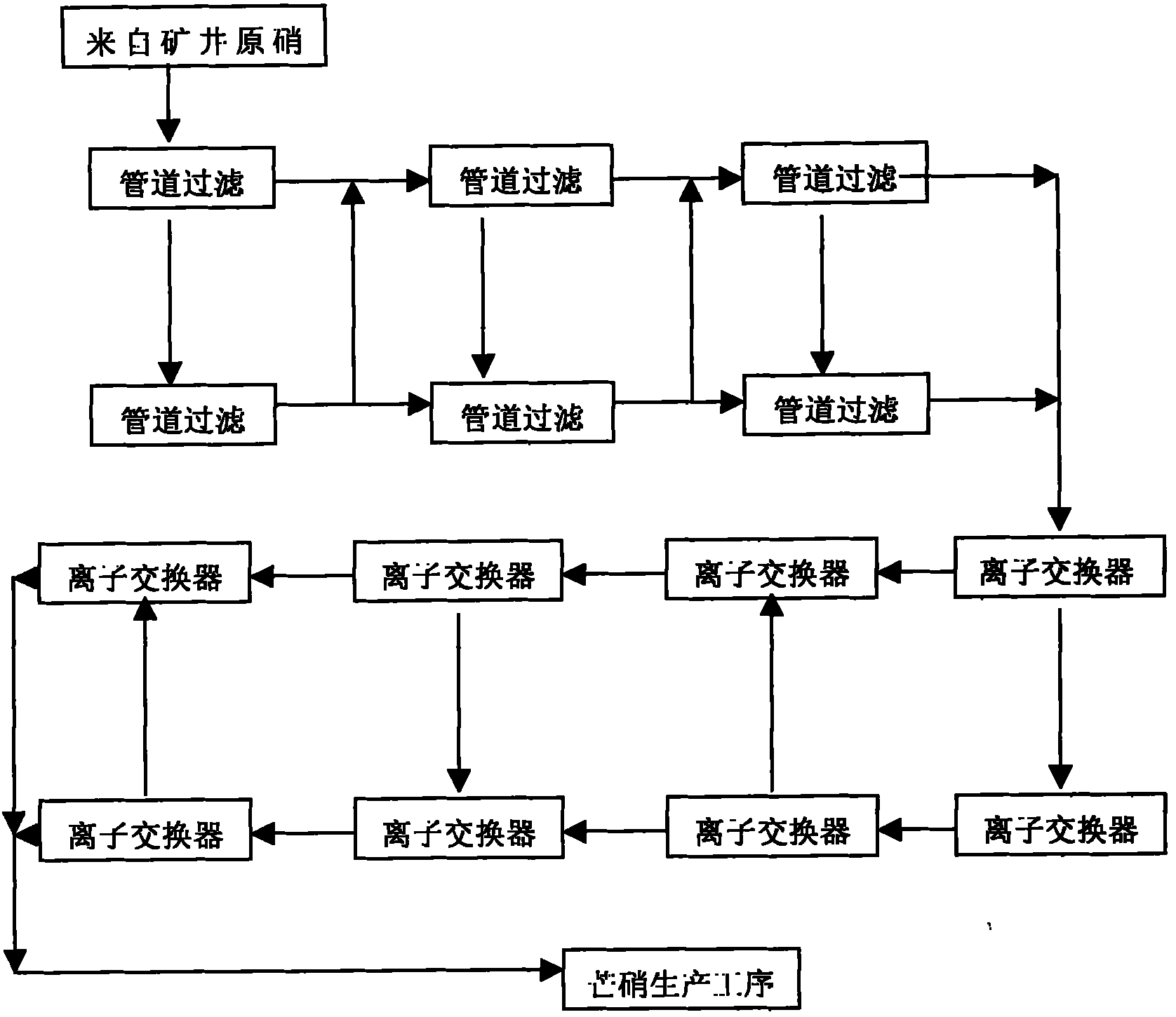

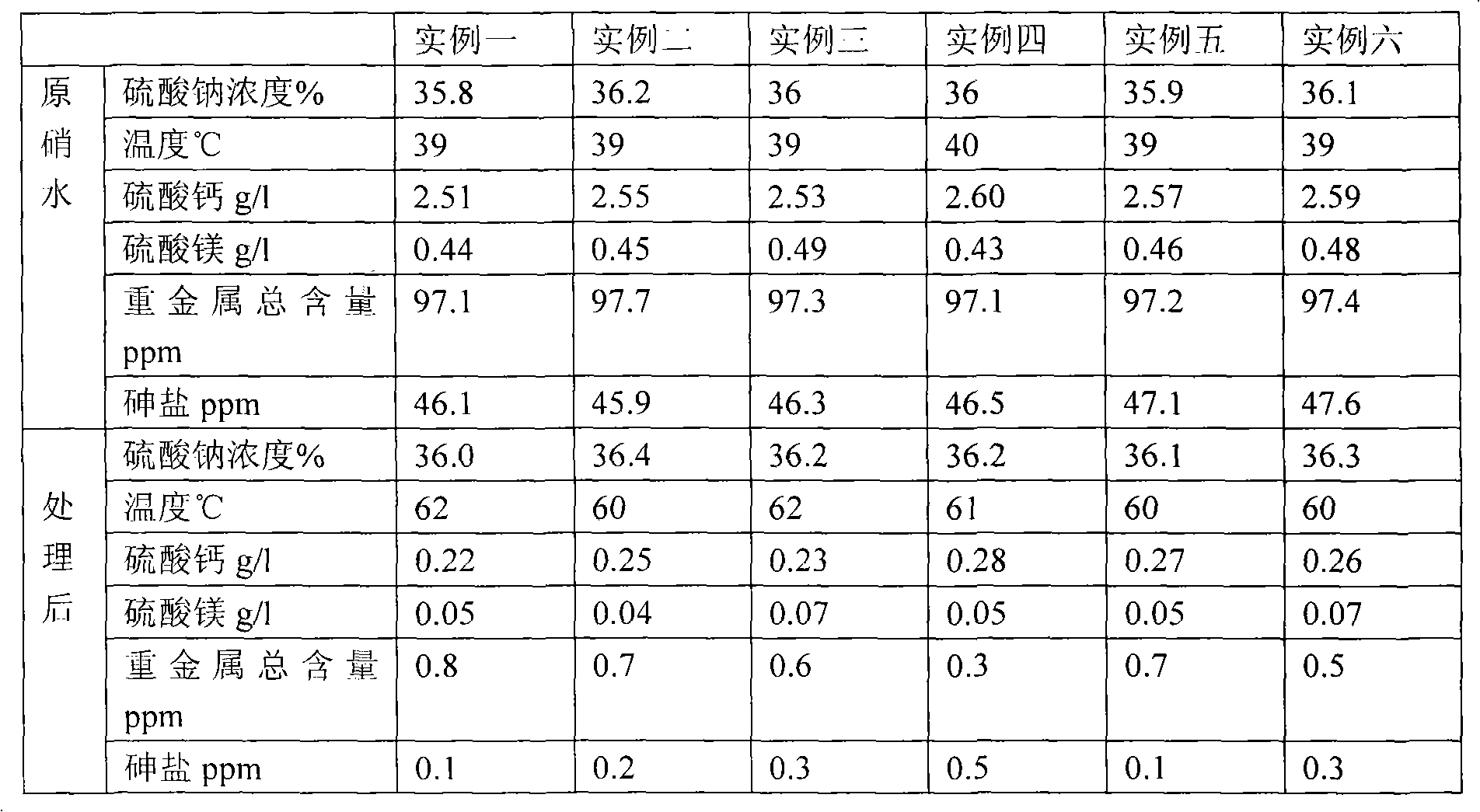

[0034] Example 1: Under the monitoring of the DCS automatic monitoring system, 35.8% concentration of raw nitric water was transported downhole to remove mechanical impurities through a three-stage pipeline filter, and refined and purified by an eight-stage ion exchanger to obtain refined nitric water with extremely low impurity content. See Table 1 for the various data of the refined nitric water produced with the above process control indicators.

Embodiment 2

[0035] Example 2: Under the monitoring of the DCS automatic monitoring system, the 36.2% concentrated raw nitric water transported down the well was removed through a four-stage pipeline filter to remove mechanical impurities, and refined and purified by a four-stage ion exchanger to obtain refined nitric water with extremely low impurity content. The obtained refined nitric water detection data are shown in Table 1.

Embodiment 3

[0036] Example 3: Under the monitoring of the DCS automatic monitoring system, the 36% concentration raw nitric water transported down the well was removed through six-stage pipeline filters to remove mechanical impurities, and refined and purified by six-stage ion exchangers to obtain refined nitric water with extremely low impurity content. The obtained refined nitric water detection data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com