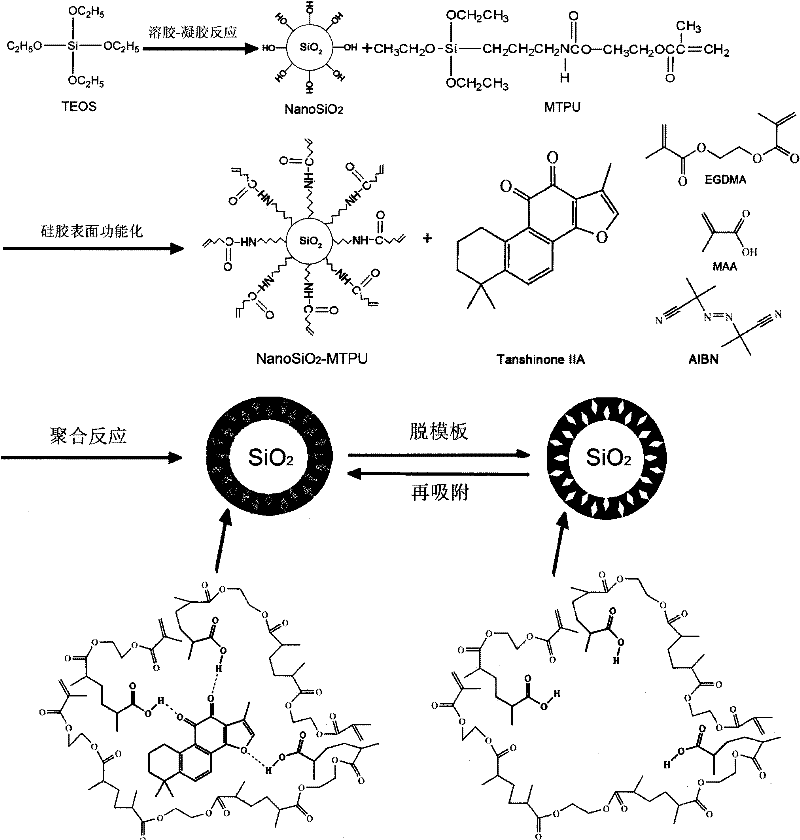

Method for preparing core-shell structured composite nano surface molecular imprinting polymer of tanshinone compound

A molecular imprinting, compound technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of low affinity efficiency, difficulty in removing template molecules, etc., and achieve binding rate and separation. High efficiency, improved mechanical strength and durability, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

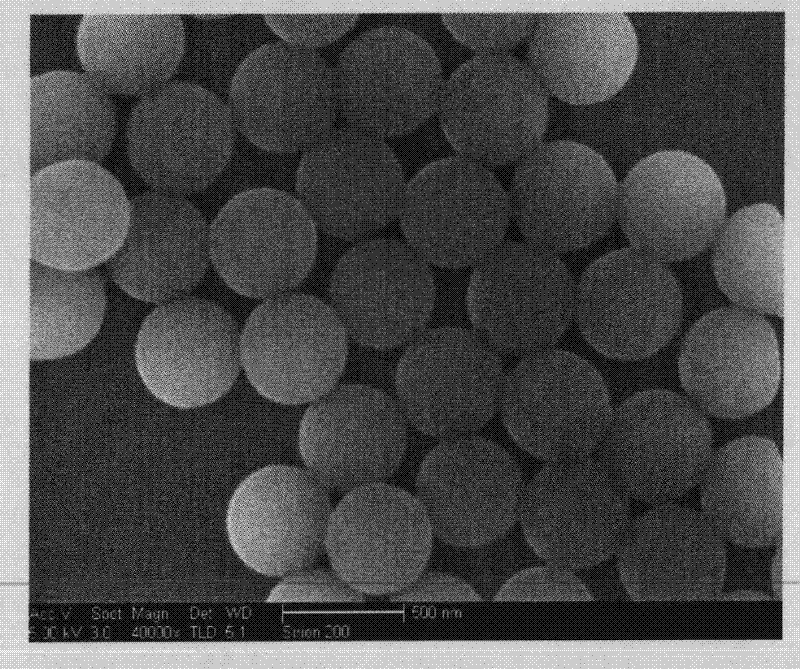

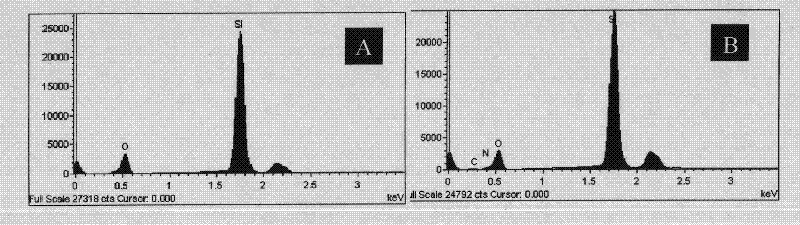

[0026] At room temperature, add 2.8mL of concentrated ammonia water, 3.1mLTEOS and 1.3mL of distilled water into 100mL of absolute ethanol solution with high-speed magnetic stirring at a speed of 500rpm, and magnetically stir for 24 hours; repeatedly ultrasonically wash with absolute ethanol until neutral, centrifuge, and store at 40°C dried under vacuum to constant weight to obtain monodisperse NanoSiO 2 particles.

[0027] Weigh the prepared SiO 2 Ultrasonic disperse 0.5g particles in 50mL toluene solution, add 7.5mL MTPU, pass N under magnetic stirring 2 Deoxygenation, rotation speed is 500rpm, stirred and refluxed at 55°C for 24h to prepare NanoSiO 2 -MTPU, then ultrasonically washed with toluene and methanol, centrifuged to remove unreacted MTPU, dried in vacuum at 40°C for 12 hours, and set aside.

[0028] Take 0.1114g of the template molecule and 0.09mL of the functional monomer MAA dissolved in 25mL of acetonitrile solution, shake well, and let stand at 25°C for 4h ...

Embodiment 2

[0032] At room temperature, quickly add 12mL concentrated ammonia water, 3.6mL TEOS and 2.1mL distilled water into 100mL absolute ethanol solution with high-speed magnetic stirring at a speed of 1500rpm, and magnetically stir for 24 hours; repeatedly ultrasonically wash with absolute ethanol until neutral, centrifuge, and store at 40°C dried under vacuum to constant weight to obtain monodisperse NanoSiO 2 particles.

[0033] Weigh the prepared SiO 2 Ultrasonic dispersion of 0.5g of particles in 50mL of toluene solution, adding 12.5mL of MTPU, deoxygenation by passing nitrogen gas under magnetic stirring at 500rpm, stirring and reflux at 55°C for 24h, to prepare NanoSiO 2 -MTPU, then ultrasonically washed with toluene and methanol, centrifuged to remove unreacted MTPU, dried in vacuum at 40°C for 12 hours, and set aside.

[0034] Take 0.1114g of the template molecule and 0.11mL of the functional monomer MAA dissolved in 25mL of acetonitrile solution, shake well, and let stand...

Embodiment 3

[0038] At room temperature, quickly add 4.1mL concentrated ammonia water, 3.8mL TEOS and 1.7mL distilled water into 100mL absolute ethanol solution with high-speed magnetic stirring at a speed of 1000rpm, and magnetically stir for 24 hours; repeatedly ultrasonically wash with absolute ethanol until neutral, and centrifuge for 40 The monodisperse NanoSiO was prepared by vacuum drying at ℃ to constant weight. 2 particles.

[0039] Weigh the prepared SiO 2 Ultrasonic dispersion of 0.5g of particles in 50mL of toluene solution, adding 10mL of MTPU, nitrogen deoxygenation under magnetic stirring, rotation speed of 500rpm, stirring and reflux at 55°C for 24h, prepared NanoSiO 2 -MTPU, then ultrasonically washed with toluene and methanol, centrifuged to remove unreacted MTPU, dried in vacuum at 40°C for 12 hours, and set aside.

[0040] Take 0.1114g of the template molecule and 0.13mL of the functional monomer MAA in 25mL of acetonitrile solution, shake well, and let stand at 25°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com