Method for constructing cast coping part through multi-phase strain

A construction method and technology for covering beams, which are applied in bridges, bridge materials, bridge construction, etc., can solve the problems of difficult movement and unapplied weight, and achieve the effect of reducing weight, facilitating maintenance and repairing, and reducing engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

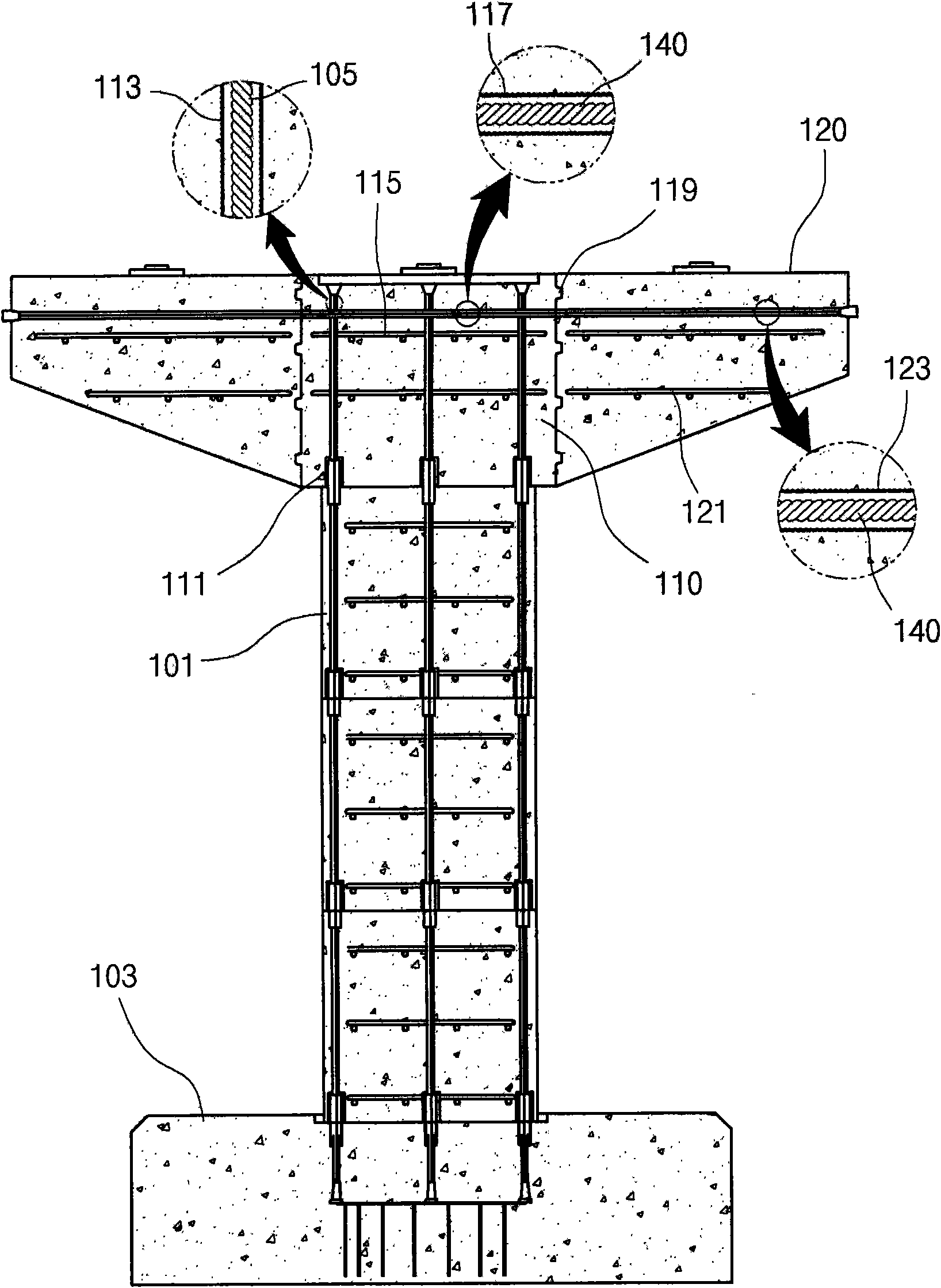

[0047] Hereinafter, the construction method of the prefabricated cap beam portion using multi-stage tensioning according to the present invention will be described in detail with reference to the accompanying drawings.

[0048] When describing the present invention below, if the specific description related to known functions or structures unnecessarily obscures the gist of the present invention, the detailed description will be omitted. In addition, terms to be described later are terms defined in consideration of functions in the present invention, and may vary depending on factors such as user and operator's intention or custom. Therefore, the definition should be based on the entire content of this specification.

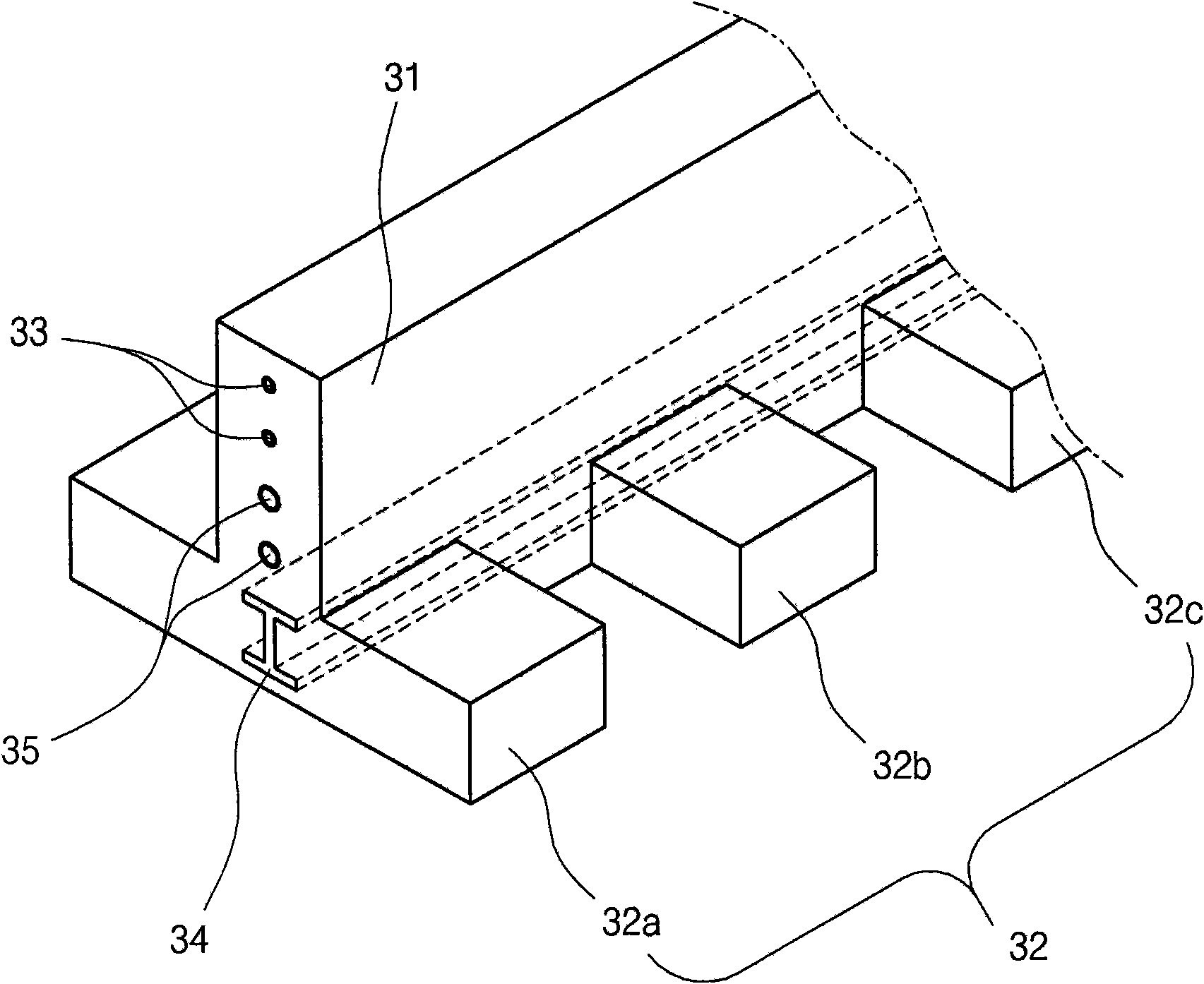

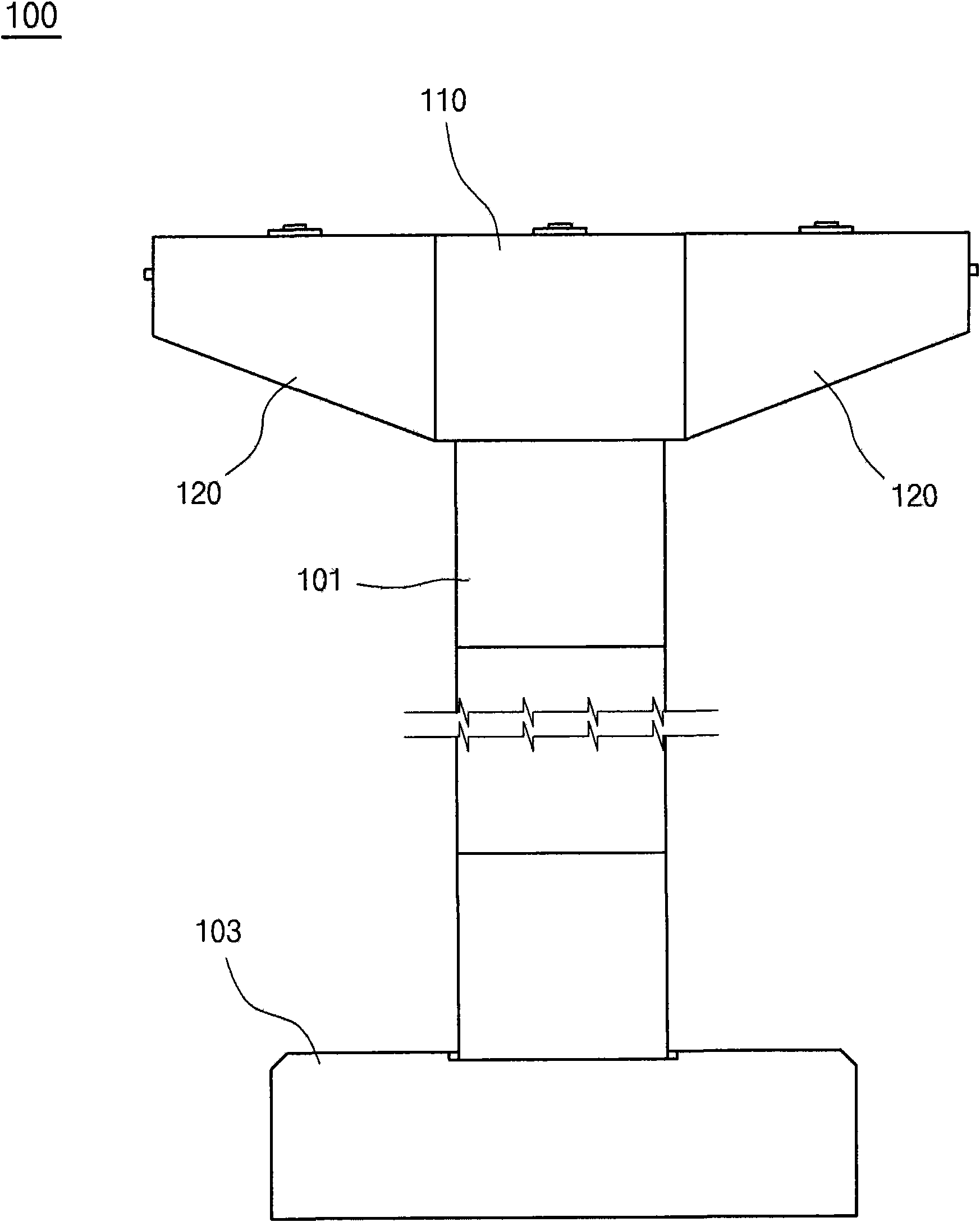

[0049] figure 2 It is a schematic diagram of the side structure of the prefabricated cover beam part of the construction method of the prefabricated cover beam part adopting multi-stage tension in the present invention. image 3 It is a schematic cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com