Self-carrying barrier-breaking and foundation-reinforcing device of shield machine

A ground reinforcement and self-portable technology, which is applied in the field of shield machines to reduce construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

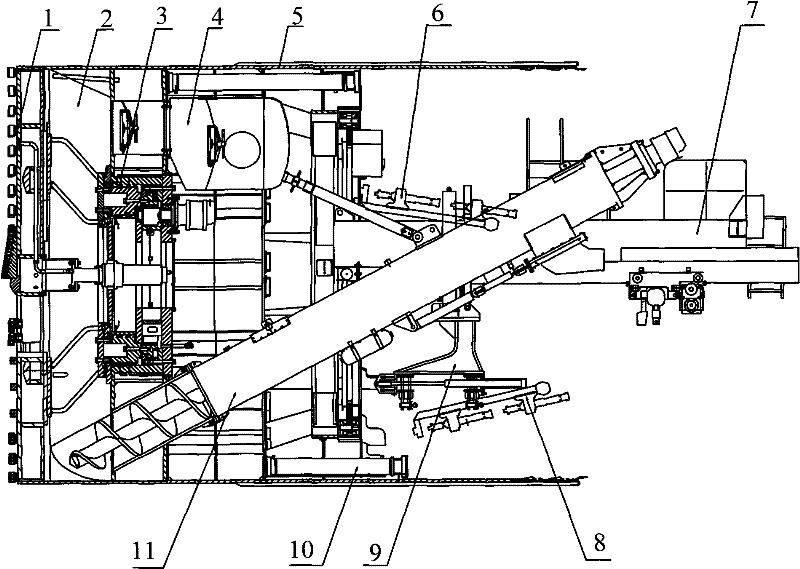

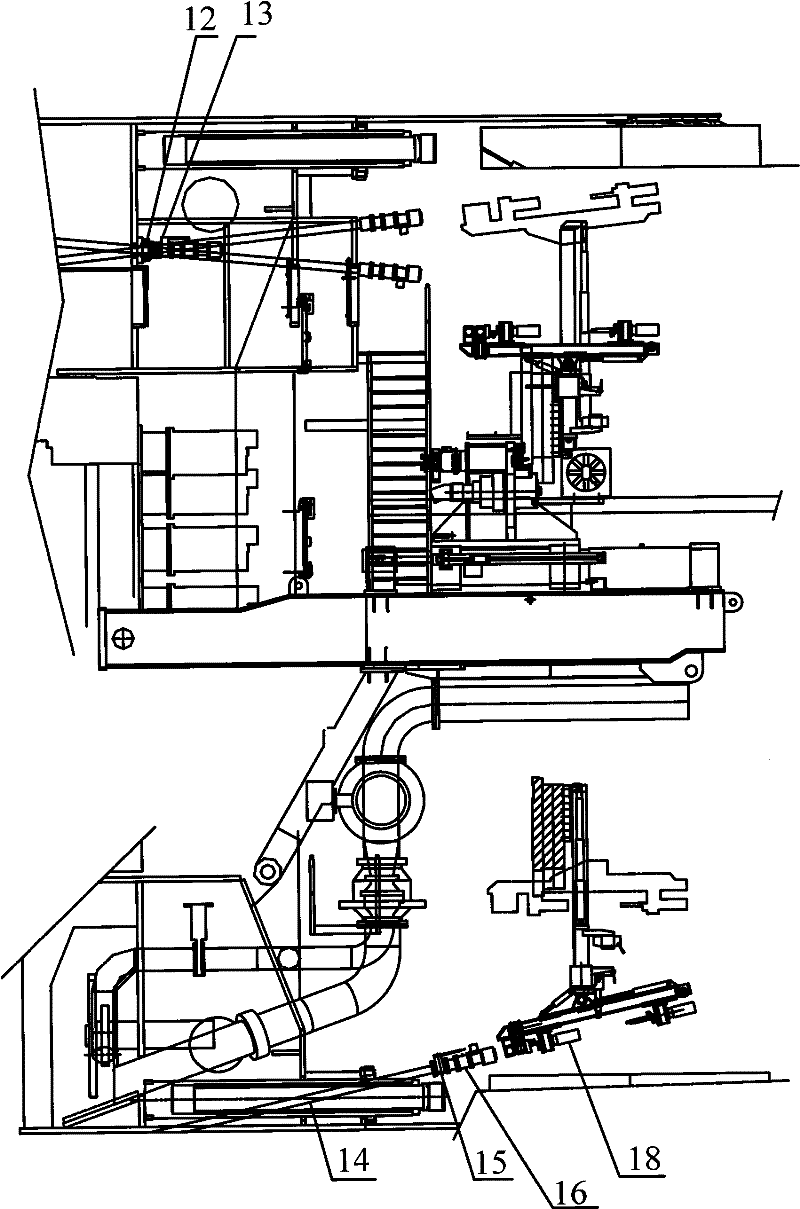

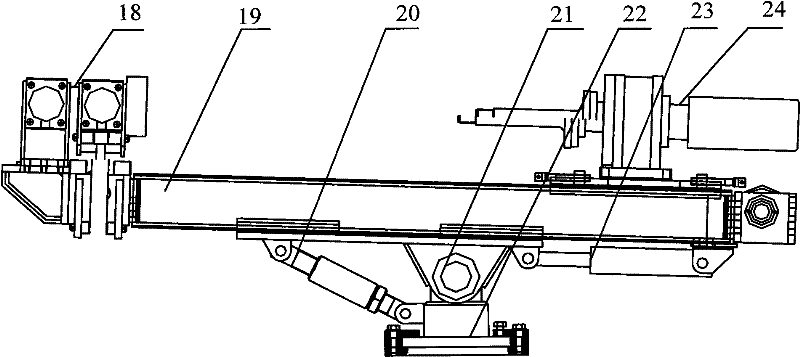

[0011] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0012] Such as figure 1 and figure 2 As shown, the self-portable crushing obstacle and foundation reinforcement device of the shield machine of the present invention include a cutter head 1, a soil bin 2, a cutter head drive mechanism 3, a pedestrian bin 4, a shield casing 5, a first drilling machine 6, Frame connecting bridge 7, second drilling machine 8, assembly machine 9, propulsion cylinder 10, screw machine 11, ball joint 12, connecting bolt 13, guide pipe 14, ball valve 15, pipe joint 16 and control valve group 18, soil bin 2 is located between the cutter head 1 and the cutter head drive mechanism 3, the cutter head drive mechanism 3 is connected to the cutter head 1 and controls the rotation of the cutter head 1, the soil bin 2, the cutter head drive mechanism 3, the pedestrian bin 4, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com