Motor compressor for vehicle air conditioner

A technology of electric compressors and automotive air conditioners, which is applied in the direction of electric components, machines/engines, liquid fuel engines, etc., can solve the problems of large drive body, increased cost and risk, and excessive volume of electric compressors, so as to save external connections Type cooling fins and cooling fans, reducing maintenance costs and facilitating product quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

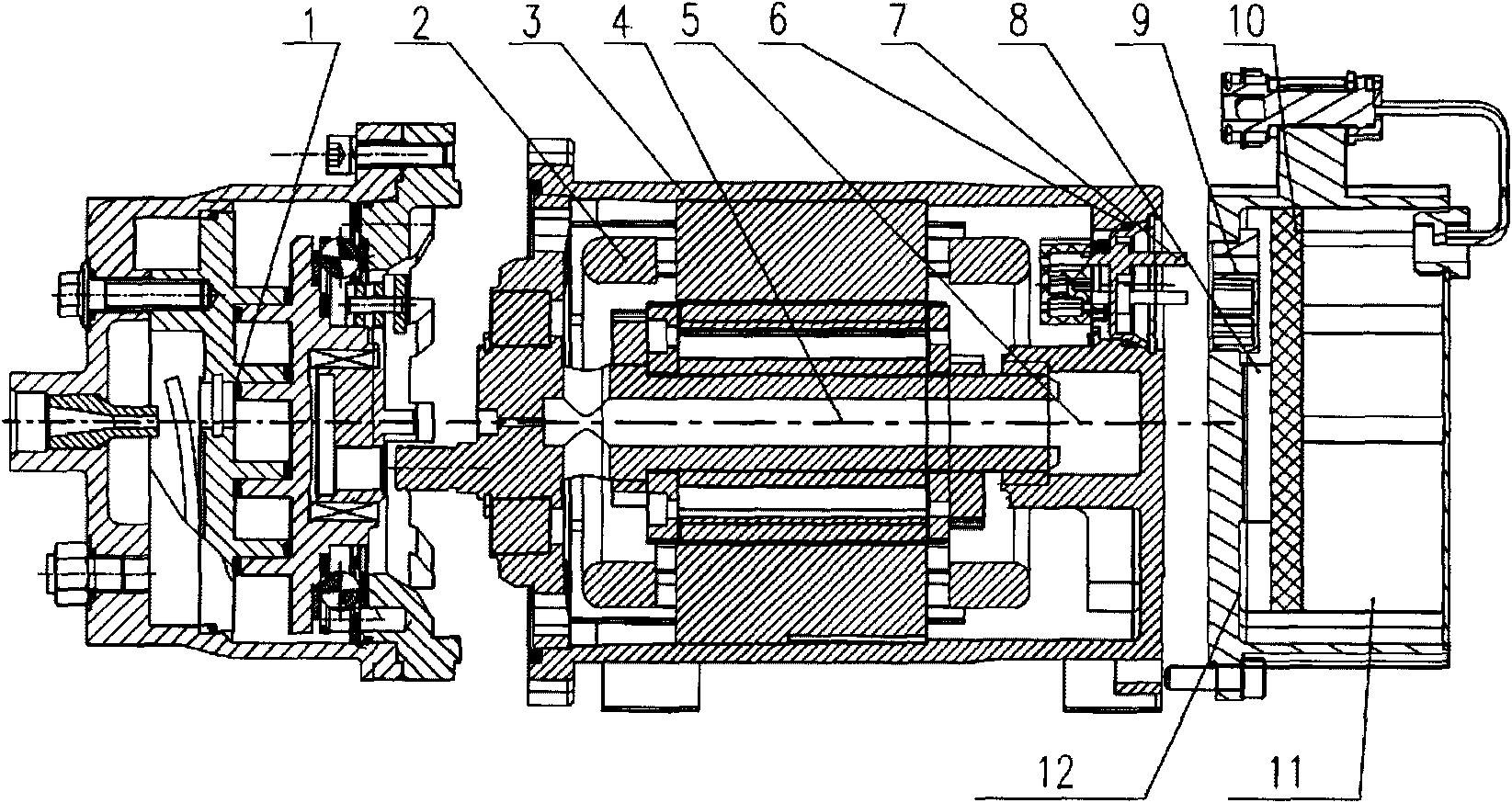

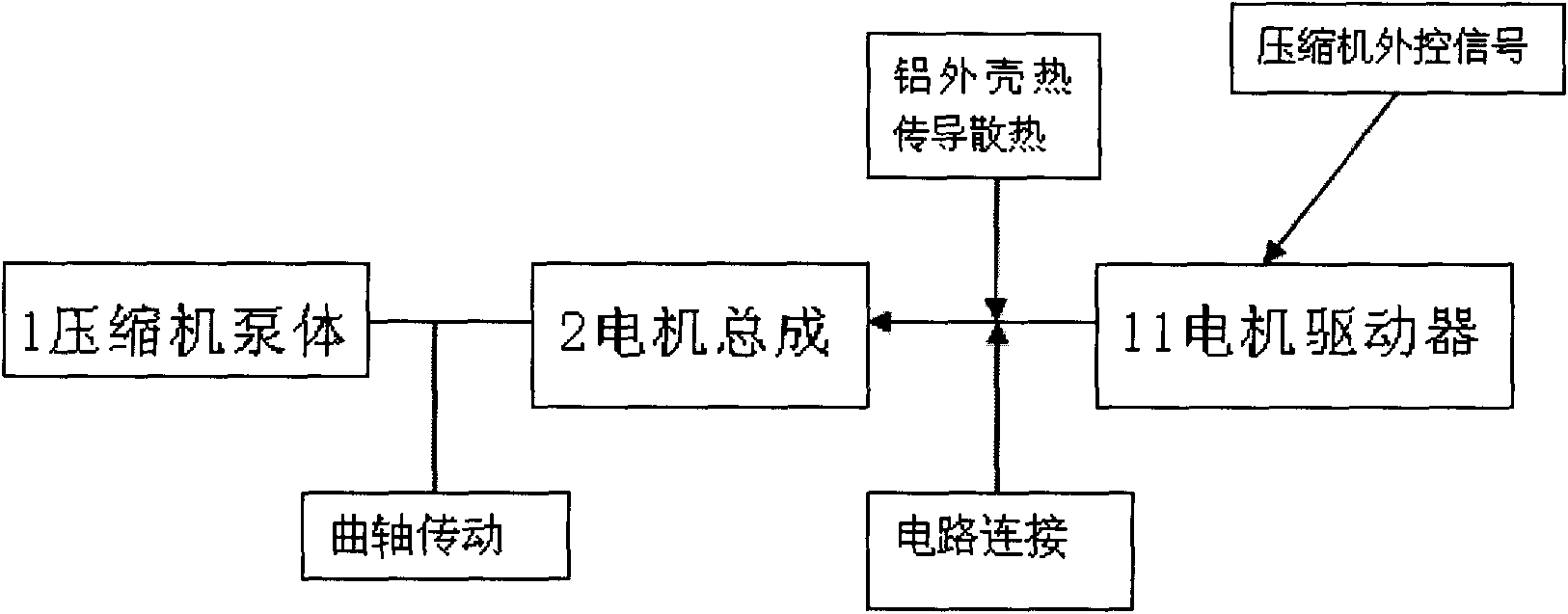

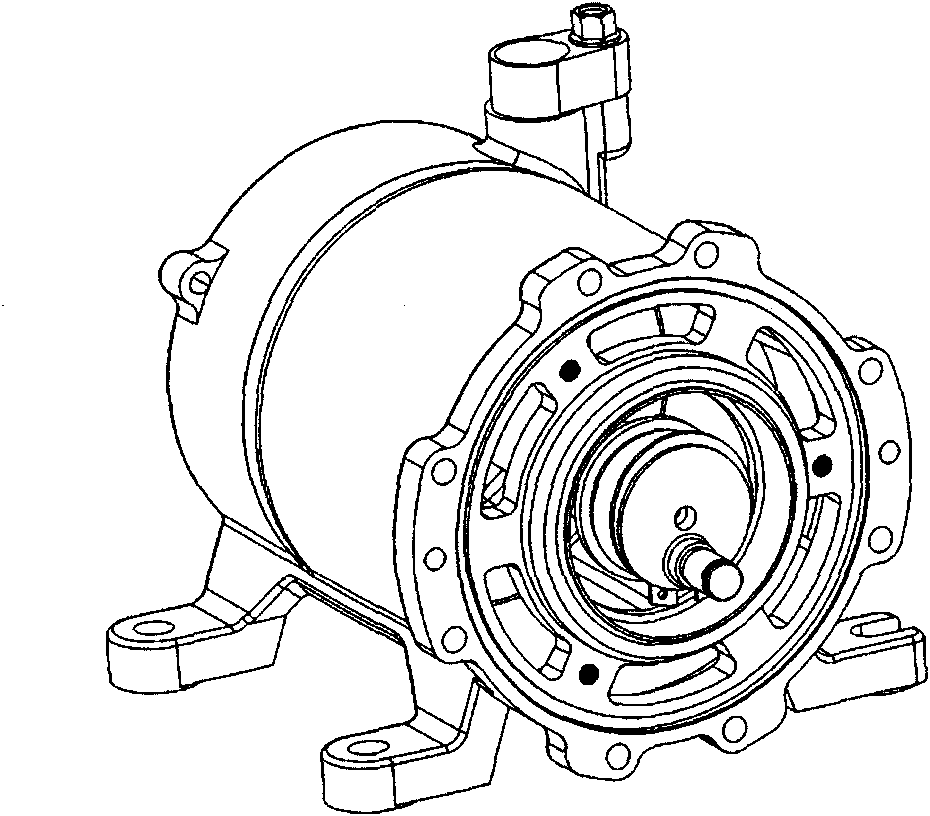

[0022] like Figure 1-4 As shown, an electric compressor for an automobile air conditioner includes a compressor pump body 1, a motor assembly 2, and a motor driver 11, and is characterized in that: the motor assembly 2 is integrally connected to the compressor pump body 1; the motor assembly 11 The motor casing 3 is embedded with a motor terminal 7, which is connected to the driver plug 9 on the motor driver 11, thereby eliminating the traditional wire between the motor driver 11 and the motor assembly 2, so that the compressor pump body 1 1. The motor assembly 2 and the motor driver 11 are integrated to reduce the volume of the electric compressor. A sealing ring 6 is arranged between the bottom of the motor terminal 7 and the motor housing 3 to ensure the waterproof, dustproof and insulation of the motor housing 3 . The motor terminal 7 and the driver plug 9 are sheathed with a plastic sheath to ensure the safety of the circuit connection between the motor driver 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com