Digital optical fiber current sensor

A technology of current sensor and digital optical fiber, which is applied in the direction of voltage/current isolation and measurement using digital measurement technology, which can solve the problems of measurement range and accuracy limitation, nonlinearity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

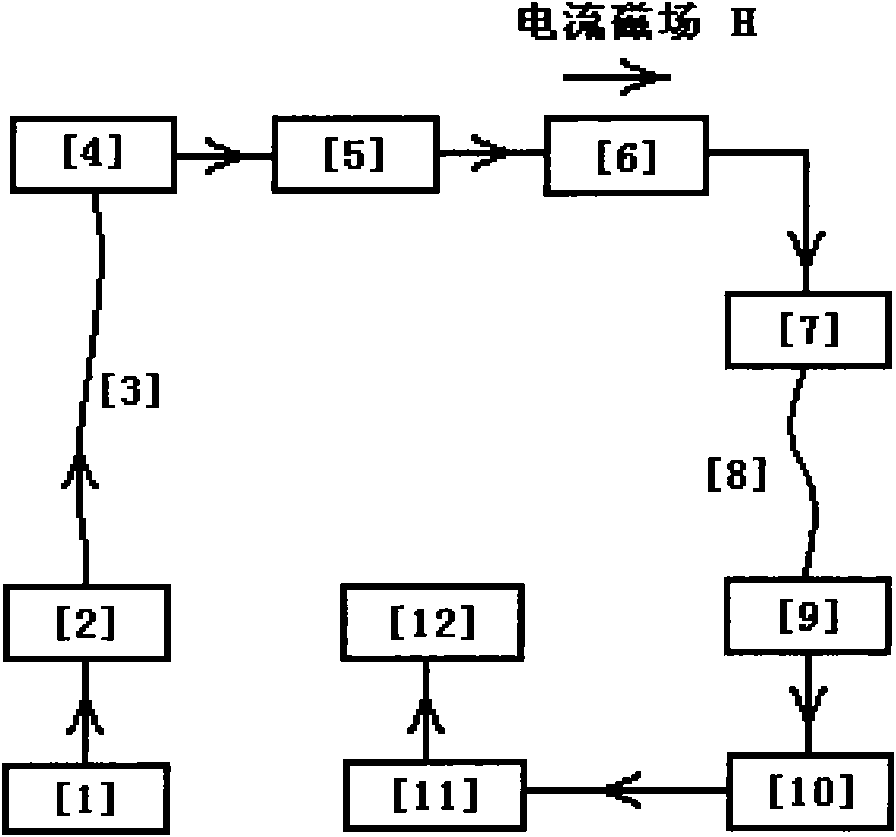

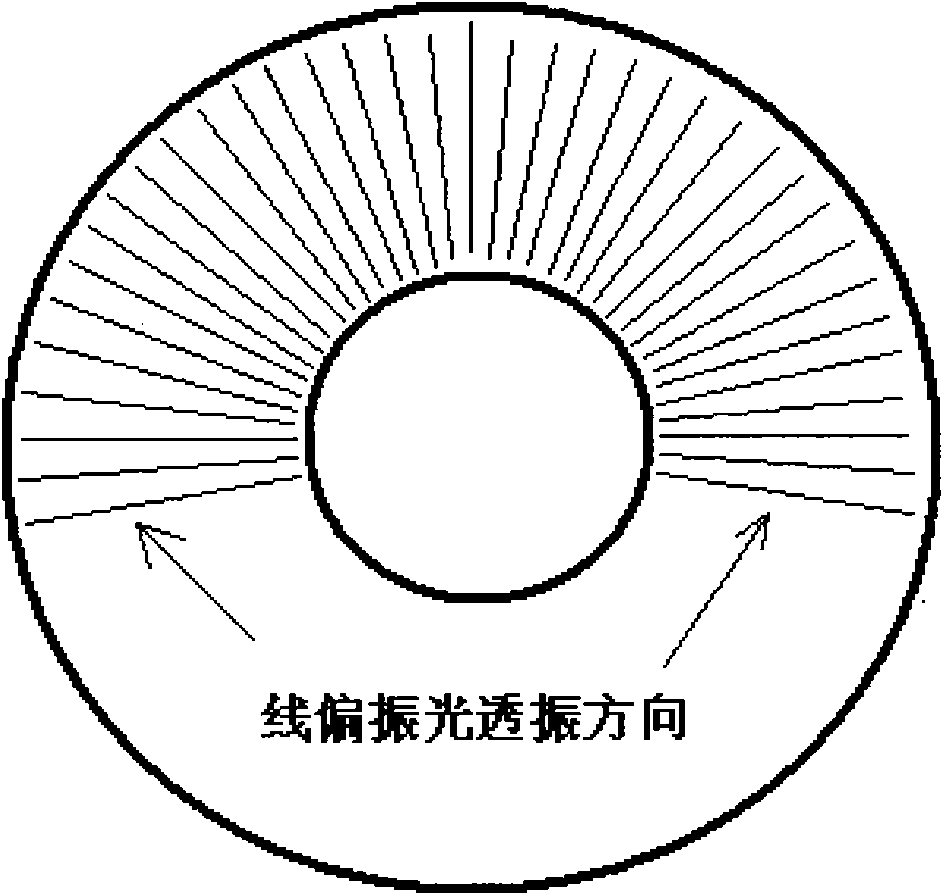

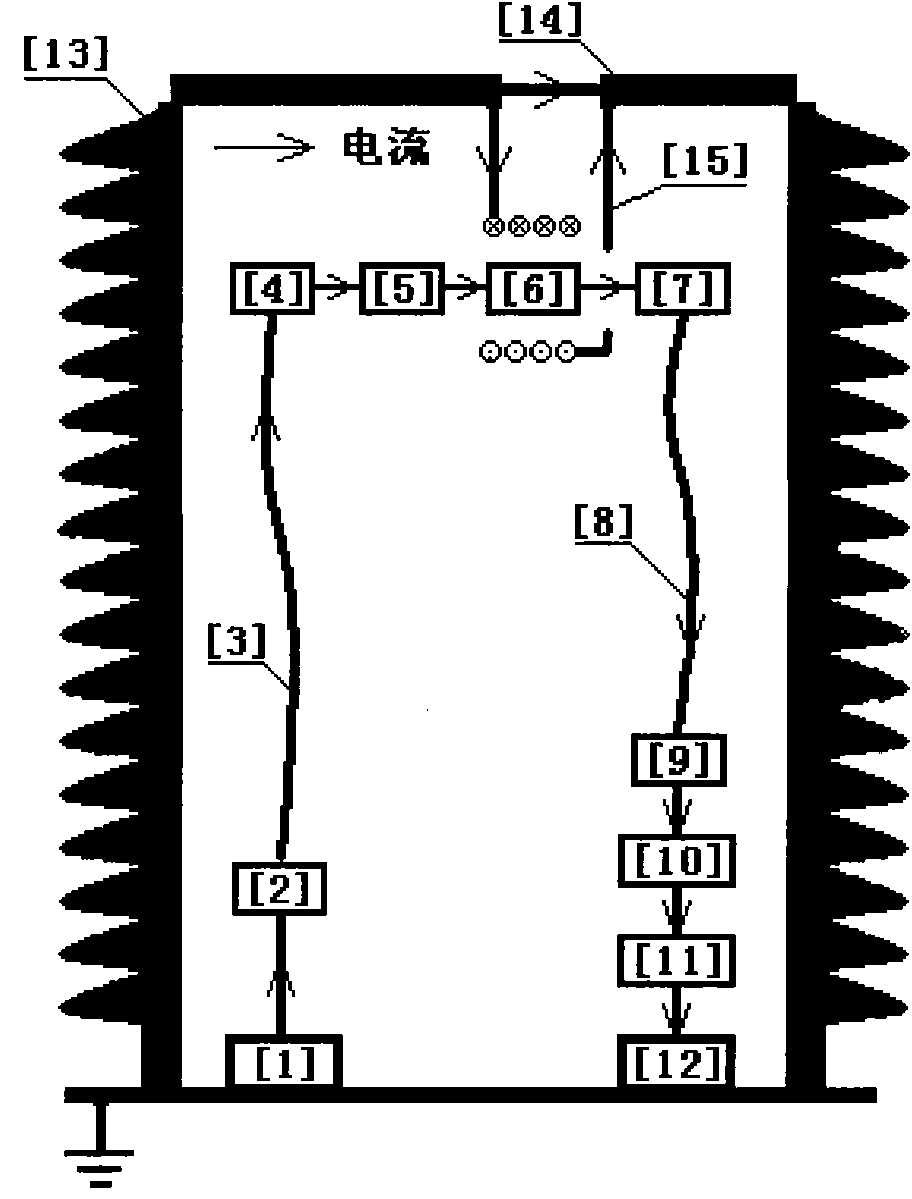

[0011] The specific implementation is as attached image 3 As shown, the laser signal [1] couples the optical signal to the transmission fiber [3] through the coupler [2] and transmits it from a low potential to a high potential, and is collimated by a collimator [4] and a polarizer [5] to obtain The linearly polarized light enters the magneto-optic crystal [6], the shunt solenoid [15] shunts the main wire current, and the magnetic field generated by the current flowing through [15] is consistent with the direction of the linearly polarized light and makes the polarization of the linearly polarized light The surface is rotated, and the linearly polarized light emitted from [6] is coupled to the transmission fiber [8] by the coupler [7] and transmitted to a low potential, collimated by the collimator [9] and expanded by the beam expander [10] Entering the circular analyzer [11], the light intensity distribution image formed by the polarized light passing through [11] is analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com