Magnetic rotation glass and its preparation technology

A preparation process, magneto-optical technology, applied in the direction of glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., to achieve the effect of good machinery, high performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

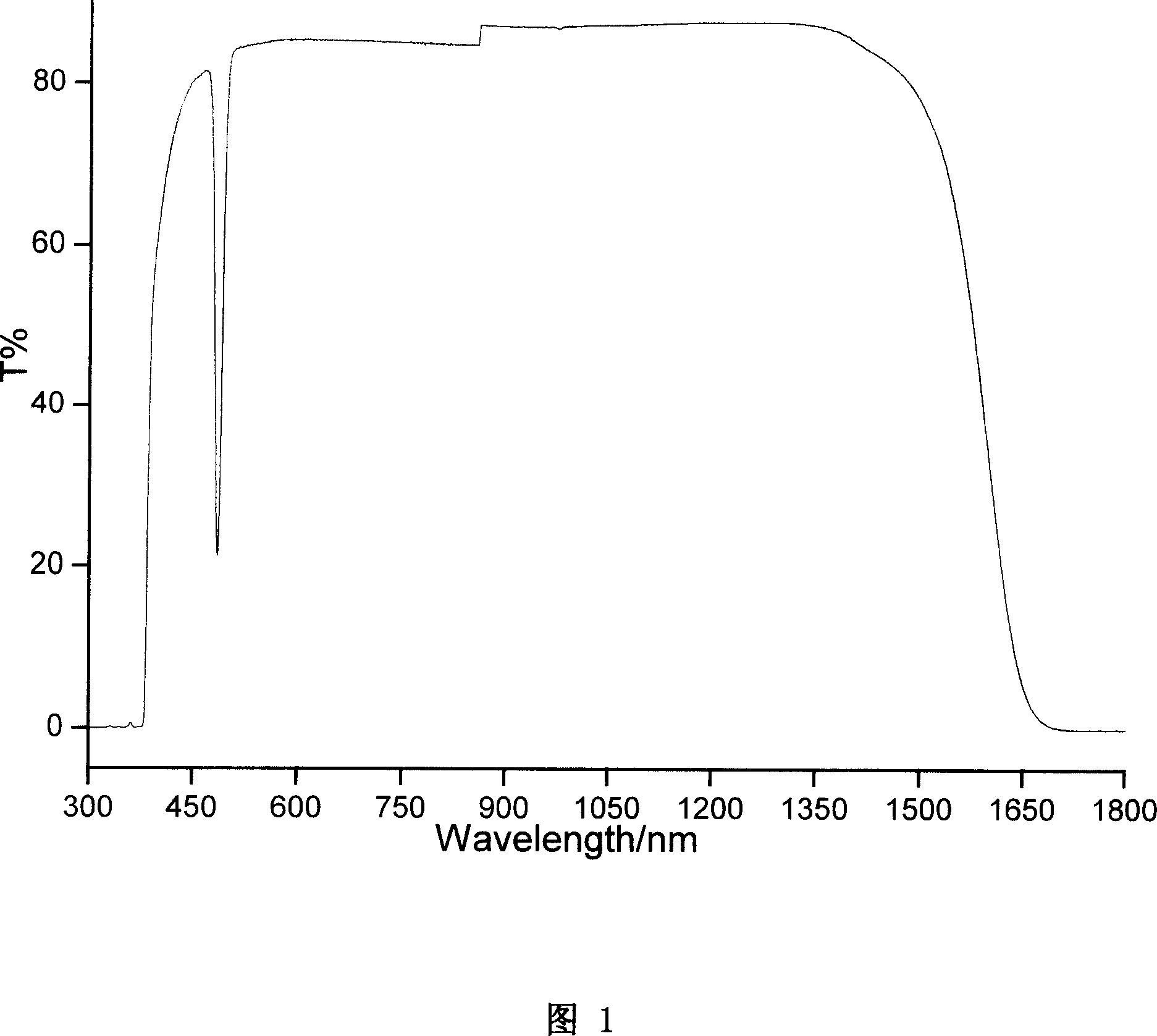

Image

Examples

Embodiment 1

[0099] 1) 20.0Tb by component 2 o 3 / 40.0B 2 o 3 +SiO2 2 / 10.0Al 2 o 3 / 16.5ZnO / 5.0ZrO 2 / 2.5InF 3 / 3.6AlF 3 +MgF 2 +CaF 2 / 2.4TiO 2 Get raw materials, mix evenly, weigh 500 grams of raw materials.

[0100] 2) Heating the platinum crucible in an electric furnace and heating it with a silicon carbide rod until the furnace temperature is 1220°C, then adding raw materials one by one.

[0101] 3) Continue to heat the electric furnace, and stir the molten glass for 3 hours at 1350°C.

[0102] 4) When the furnace temperature is lowered to 1280°C, pour the molten glass into the preheated mold.

[0103] 5) Precision annealing at 580°C in an annealing furnace.

Embodiment 2

[0105] 25.0Tb by component 2 o 3 / 50.0B 2 o 3 +SiO2 2 / 10.0ZnO / 2.5ZrO 2 / 0.5InF 3 / 12.0AlF 3 +MgF 2 +CaF 2 / Take the raw material, add the material when the furnace temperature reaches 1200°C, stir the molten glass for 3.5 hours when the temperature reaches 1320°C, pour the molten glass into the preheated copper mold at 1250°C, and precisely anneal in the annealing furnace at 580°C.

Embodiment 3

[0107] 30.0Tb by component 2 o 3 / 48.0B 2 o 3 +SiO2 2 / 15.0Al 2 o 3 / 4.5ZnO / 1.0ZrO 2 / 1.0InF 3 / 3.5TiO 2 Take the raw material, add the material when the furnace temperature is 1280°C, stir the glass melt for 4.5 hours when it reaches 1400°C, pour the glass melt into the preheated copper mold at 1300°C, and precisely anneal in the annealing furnace at 650°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com