Automatic accumulator tank charging machine

A technology for battery tanks and batteries, which is applied to battery components, circuits, electrical components, etc., can solve problems such as low work efficiency and high labor intensity, and achieve the effects of simple structure, reduced physical labor, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

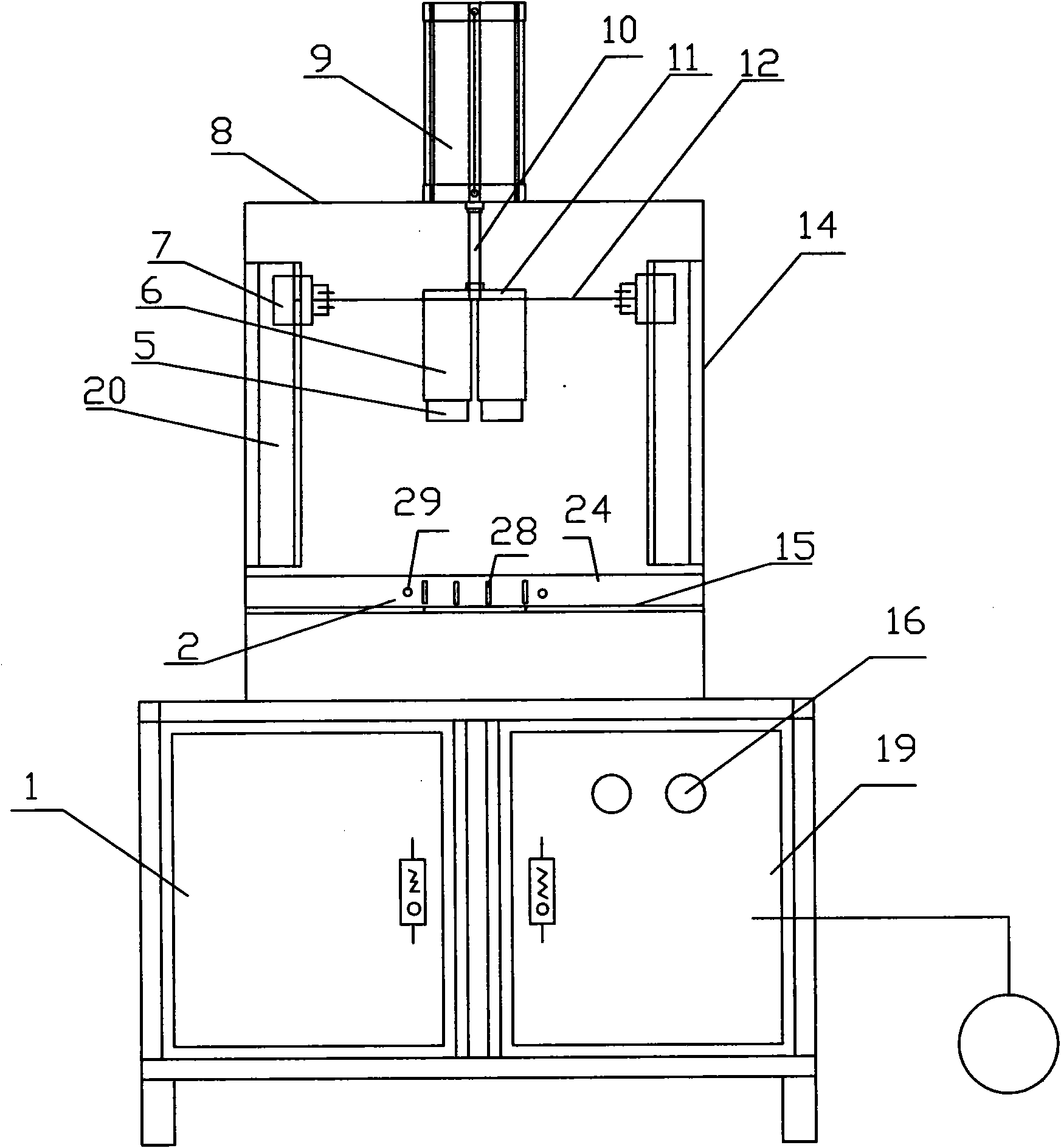

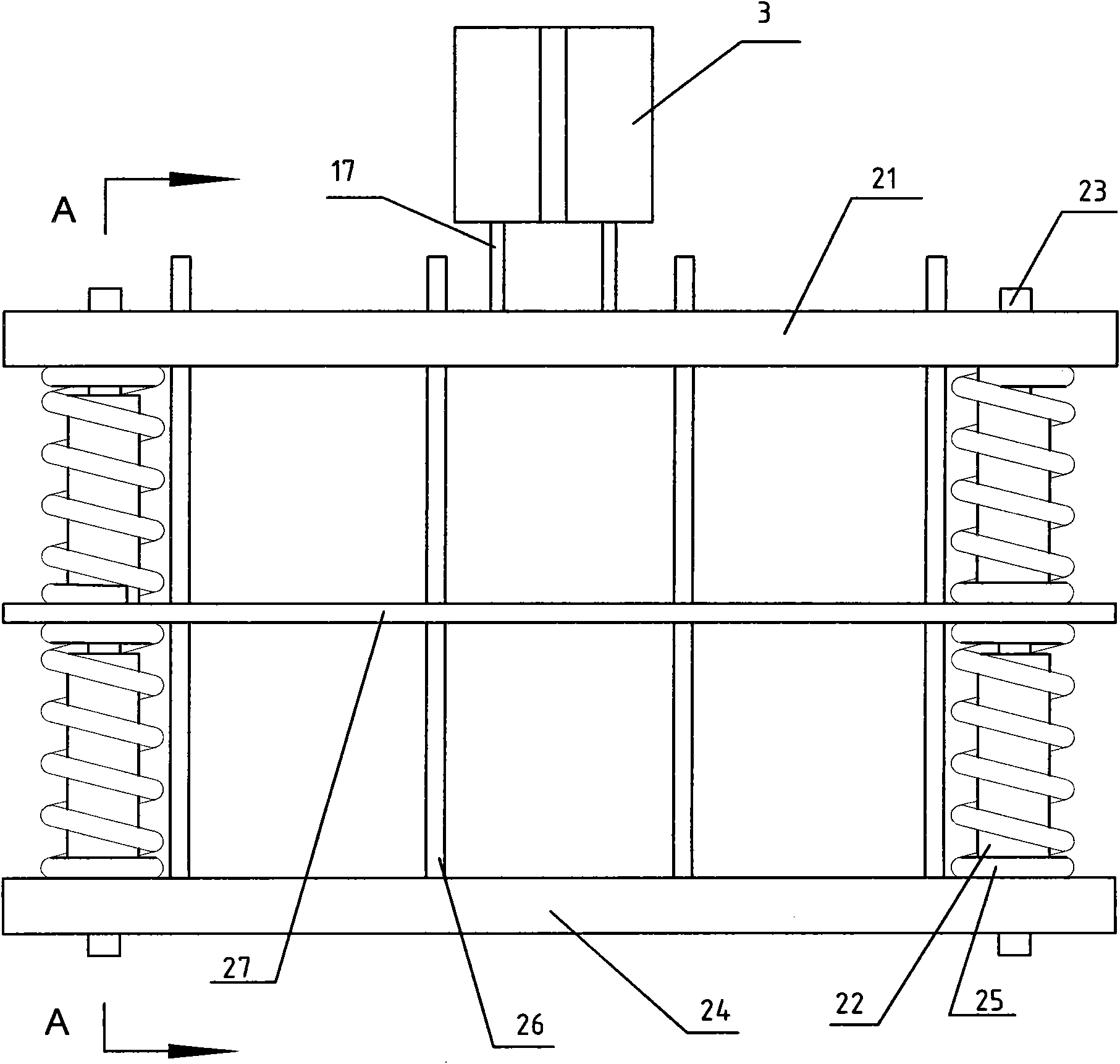

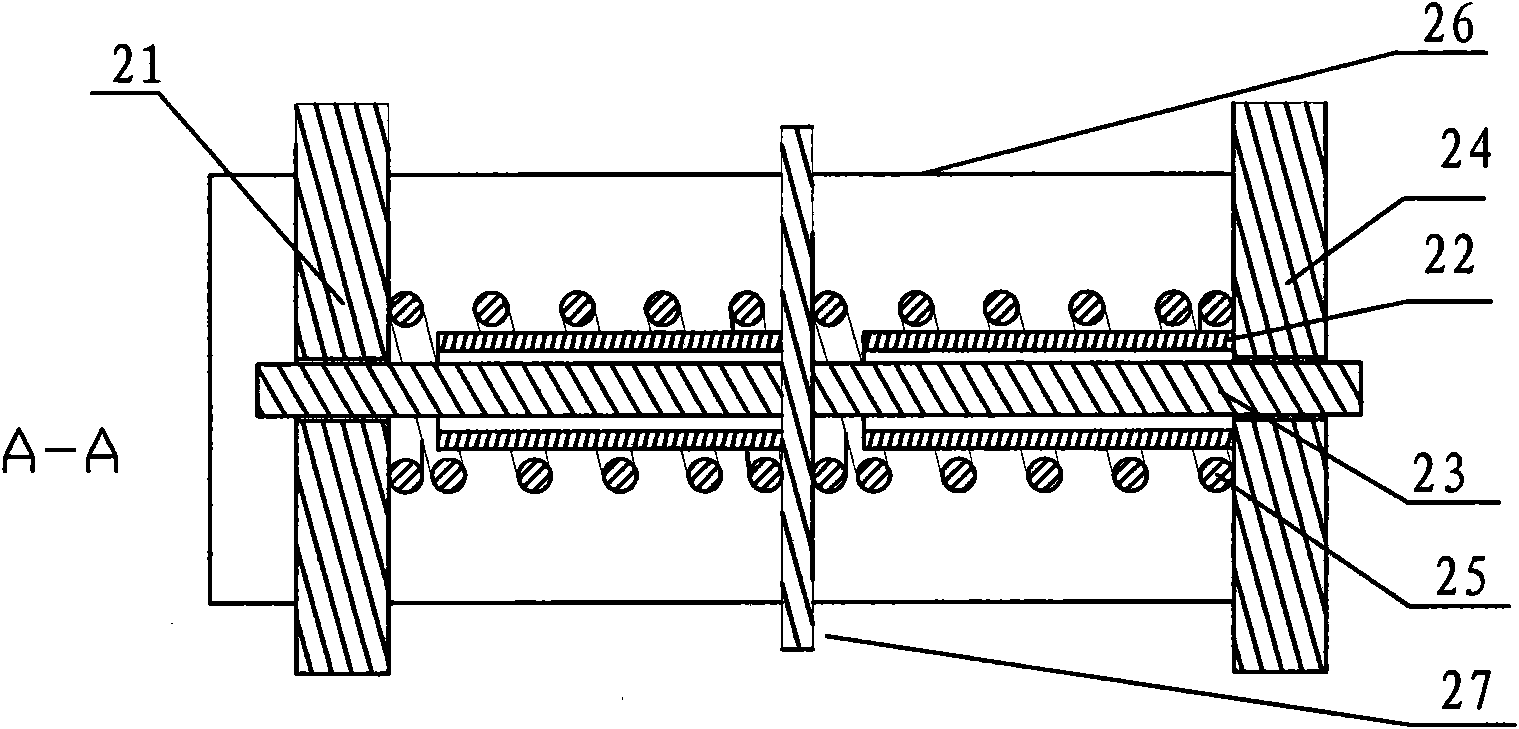

[0017] like figure 1 As shown, an automatic storage battery slotting machine includes a workbench 1 for placing battery tank boxes, two vertical protection plates 14 are arranged on both sides of the workbench 1, and a top plate 8 is erected between the tops of the two protection plates 14. A vertical cylinder 9 is installed on the top plate 8 . The bottom end of the piston rod 10 of the cylinder 9 is provided with a mounting plate 11, and six top blocks 6 are installed on the bottom surface of the mounting plate 11, and the arrangement of the top blocks 6 is consistent with the distribution of the battery slots. In order to prevent the groove loading process, an elastic block 5 is pasted on the bottom surface of the top block 6, and the material of the elastic block 5 is polyurethane with good shock resistance, wear resistance and fatigue resistance. The width of the elastic block 5 is not greater than the distance between the two bus bars on the battery pole group.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com