Offshore drift line type net cage system

A technology of cages and floating ropes, applied in the field of cages, can solve the problems of poor self-purification ability, small scale, and poor wind and wave resistance in the breeding environment, and achieve the effects of easy promotion and industrialization, scientific design and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

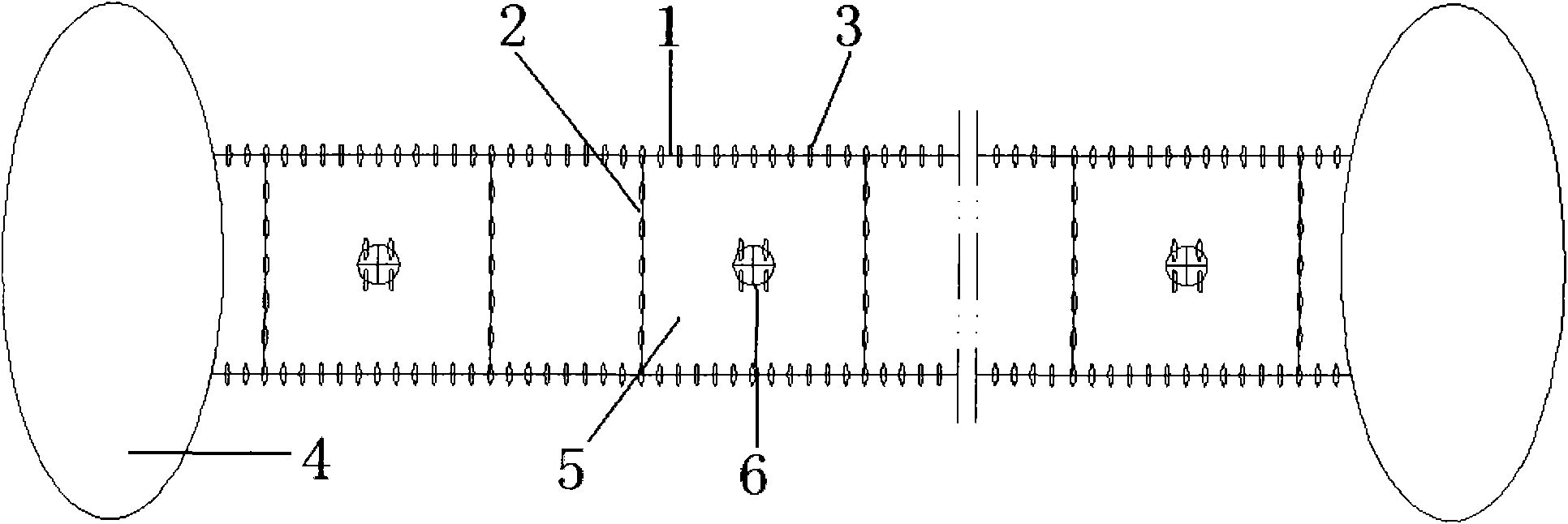

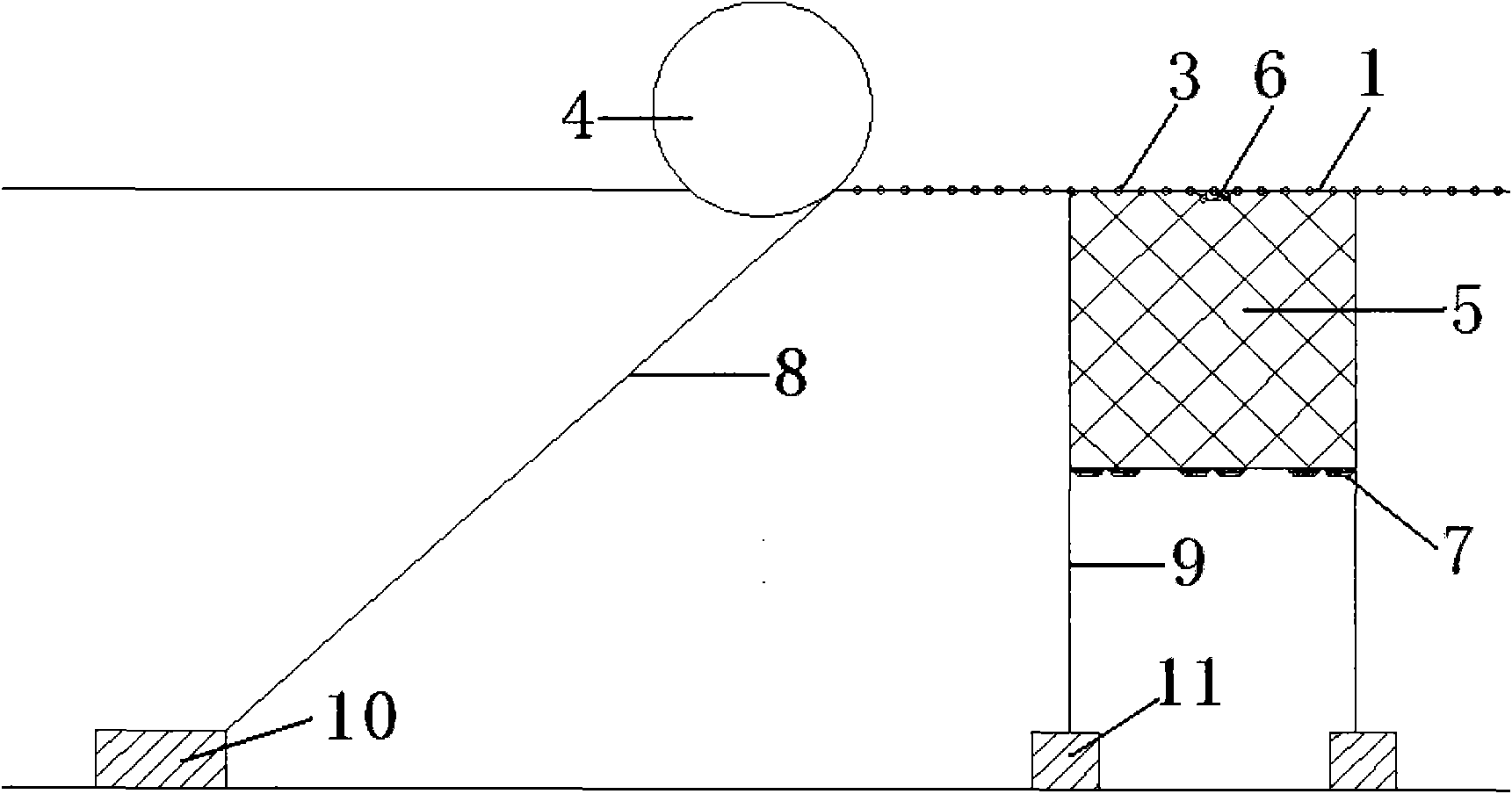

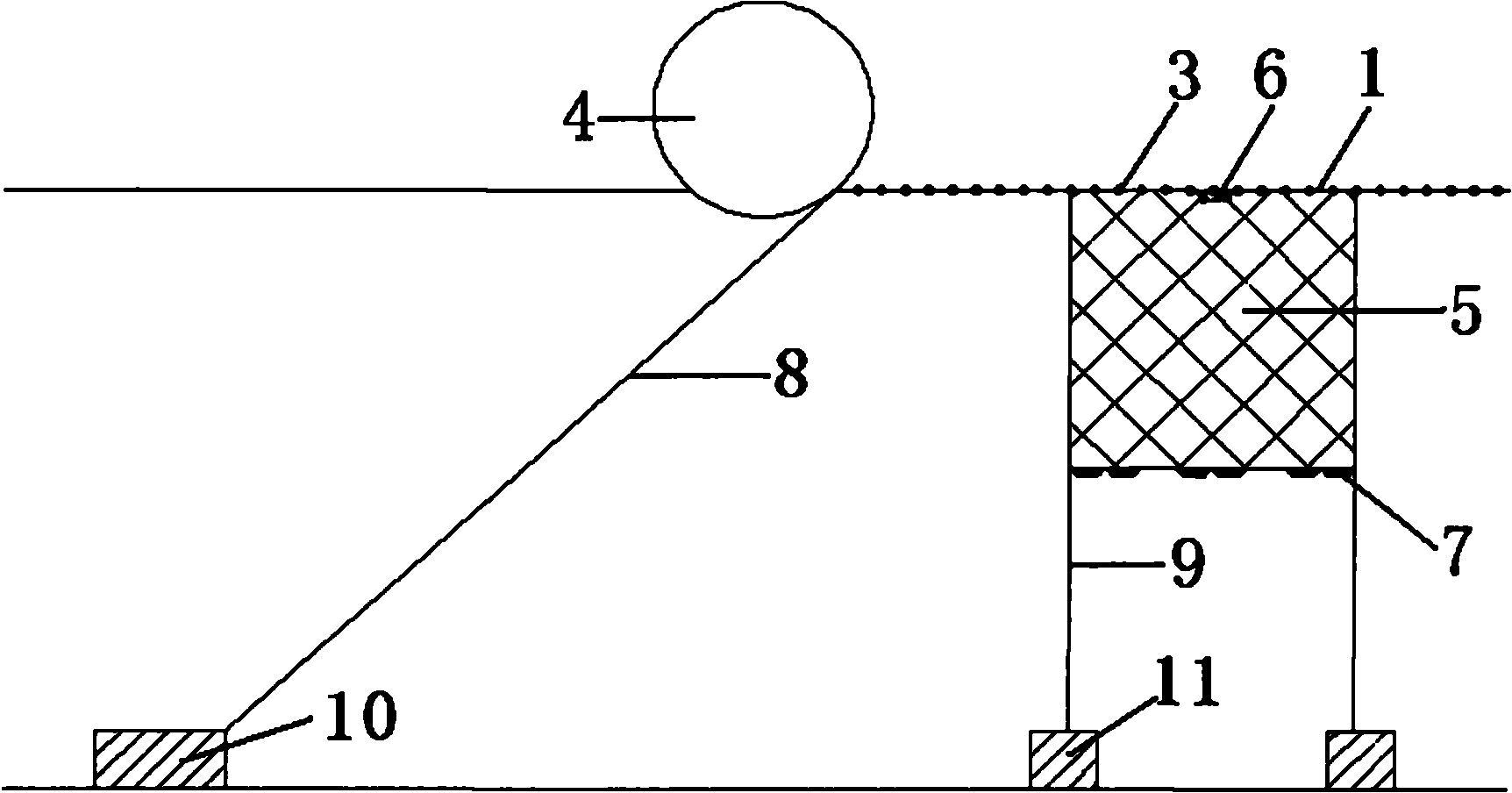

[0021] Such as figure 1 and figure 2 Shown, offshore floating rope type net cage system of the present invention comprises framework, net cage, anchor rope and iron anchor. The main cable 1 made of two submerged nylon ropes with a total breaking strength of 28,000 kg and the auxiliary cable 2 made of 20 polyvinyl chloride ropes are connected to form a frame with 10 cage openings and a spacing of 3.5m between the cage openings. , the main and auxiliary cables of the frame are bound with buoys 3 connected in series with buoy ropes and with a spacing of 42 cm, and a floating body 4 is respectively tied at the two ends of the main cables. The specification of cage 5 is 6m×6m×6m in length×width×depth. It is moderate in size and relatively convenient to manufacture and operate. It is made of 71mm nylon mesh, which is sewn with 53-thread nylon rope. . The net cages are bound at the mouth of each net cage in the frame, arranged in a single row, and the distance between groups is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com