Microcapsules containing active ingredients

A technology of microcapsules and active substances, which is applied in the direction of microcapsule preparations, surface active detergent compositions, and microsphere preparations, and can solve the problems of undisclosed active ingredient compositions and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

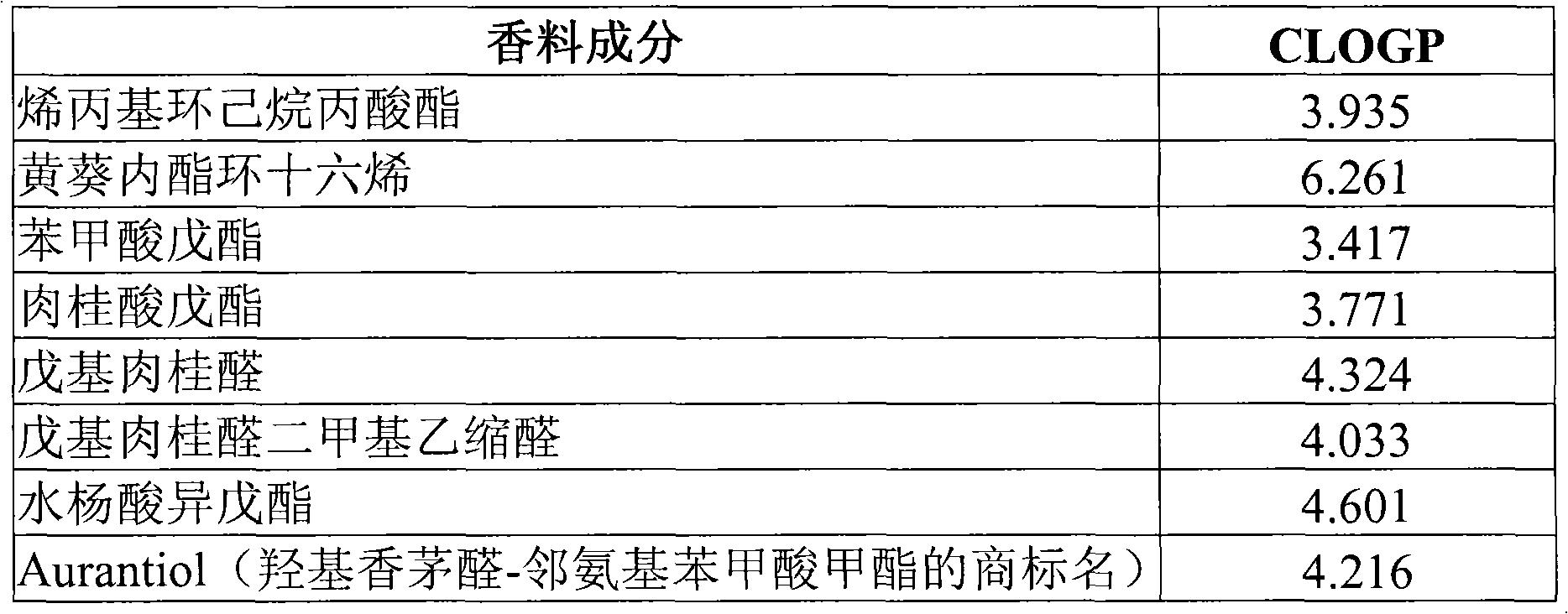

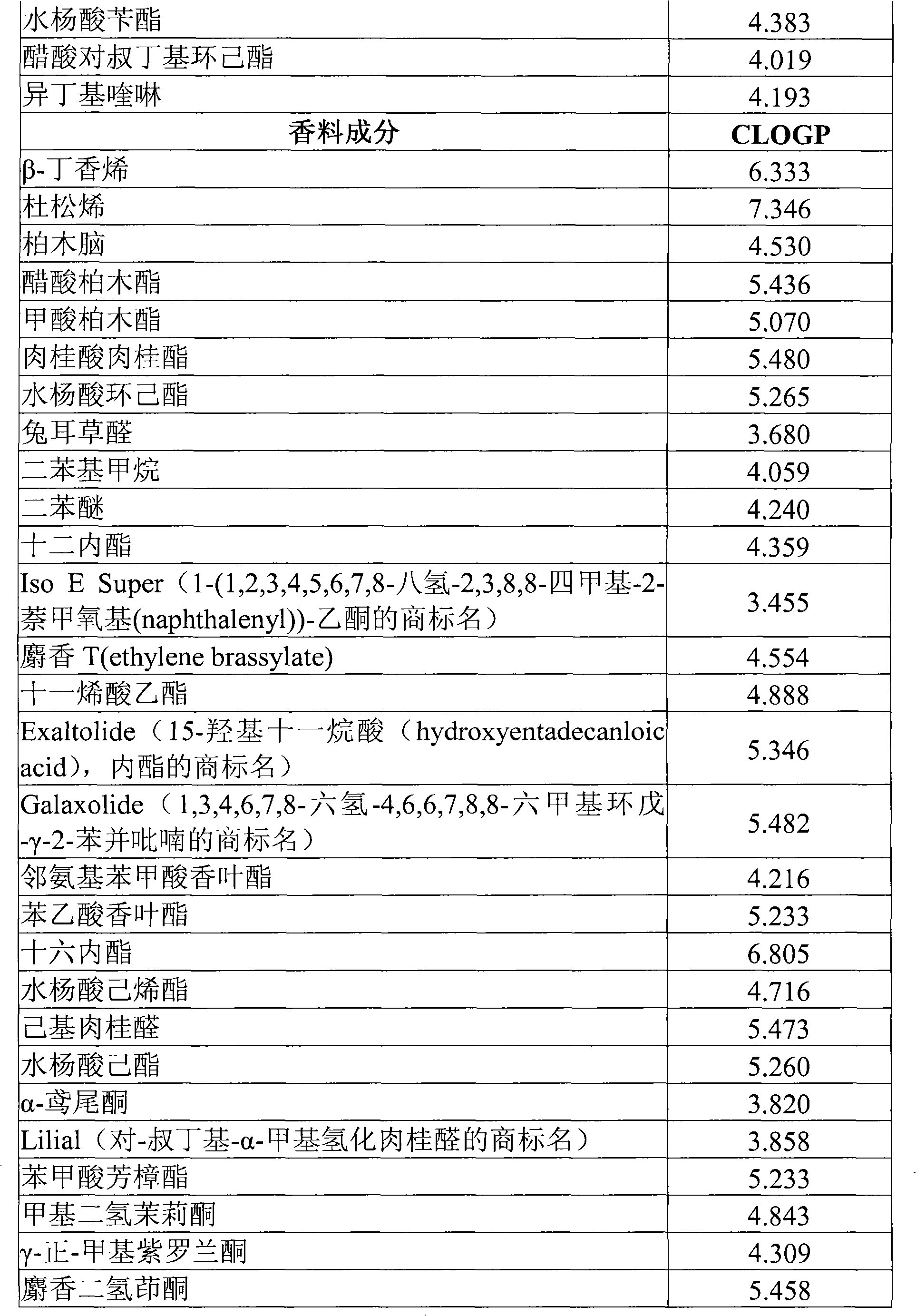

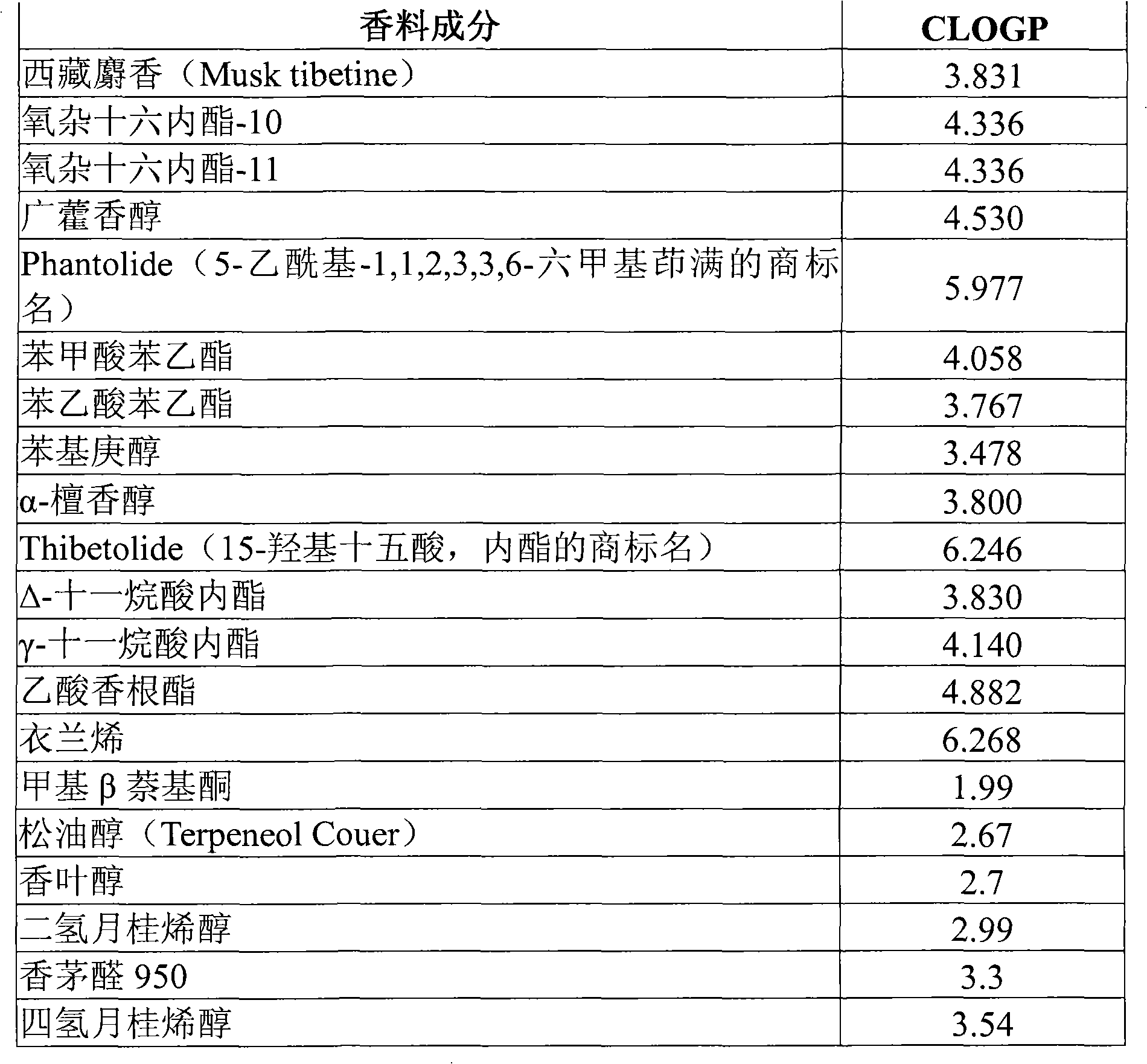

Image

Examples

Embodiment 1

[0064] Method A: Preparation of silica capsules by direct emulsification

[0065] 12 grams of tetraethylorthosilicate (TEOS) was mixed with 140 grams of aromatic oil to form an oil phase, and the mixture was cooled in an ice bath. The fragrances are suitable for personal care applications. In a separate container, prepare 150 g of 0.5% aqueous surfactant (CTAC: cetyltrimethylammonium chloride, from Aldrich Chemical Company, Milwaukee) by dissolving the required amount of surfactant in distilled water and cooling in an ice bath , Wisconsin, USA 25% solution). The oily phase was then poured into the aqueous phase and the mixture was homogenized using a high shear mixer (Ultra Turrax T 25Basic, IKA, Werke).

[0066] Add four drops of antifoam to suppress foam formation. The pH of the system was maintained at about 3.9. The system was left at room temperature and cured for an extended period of time. The capsules formed are well dispersed and typically have particle sizes in ...

Embodiment 2

[0069] Preparation of Silica Capsules by Direct Emulsification of Higher Wall Polymer Loading

[0070] The method is carried out by using the same perfume as in Example 1 and the same method as in Example 1. However, the amount of TEOS was increased to 36 g, and the amount of flavor remained the same.

Embodiment 3

[0072] Method B: Directly emulsify the oil, then add TEOS to prepare silica capsules: 1-step post-addition method.

[0073] Step 1. Preparation of fragrance emulsion

[0074] 140g of aromatic oil was placed in a round bottom container and cooled in an ice bath. In a separate container, a 0.5% aqueous surfactant solution (150 g) was prepared by dissolving the required amount of solid surfactant in distilled water and cooling in an ice bath. The oily phase was then poured into the aqueous phase and the mixture was homogenized with a high shear mixer (Ultra Turrax T 25Basic, IKA, Werke). Add four drops of antifoam to suppress foam formation.

[0075] Step 2. Add TEOS to the fragrance emulsion.

[0076] 24 g of wall-forming TEOS were weighed out in a clean dry container and transferred to a dropping funnel. Then, drop it into the fragrance emulsion prepared in step 1 under continuous stirring. Once the TEOS has been added, the stirring speed is reduced. The system is then le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com