Straight wire drawing machine system

A straight-forward wire drawing machine and wire drawing technology, applied in the field of wire drawing machines, can solve the problems of complicated programming and calculation, difficult to popularize and apply, low accuracy, etc., achieve strong practicability, simplify PLC programming and debugging work, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

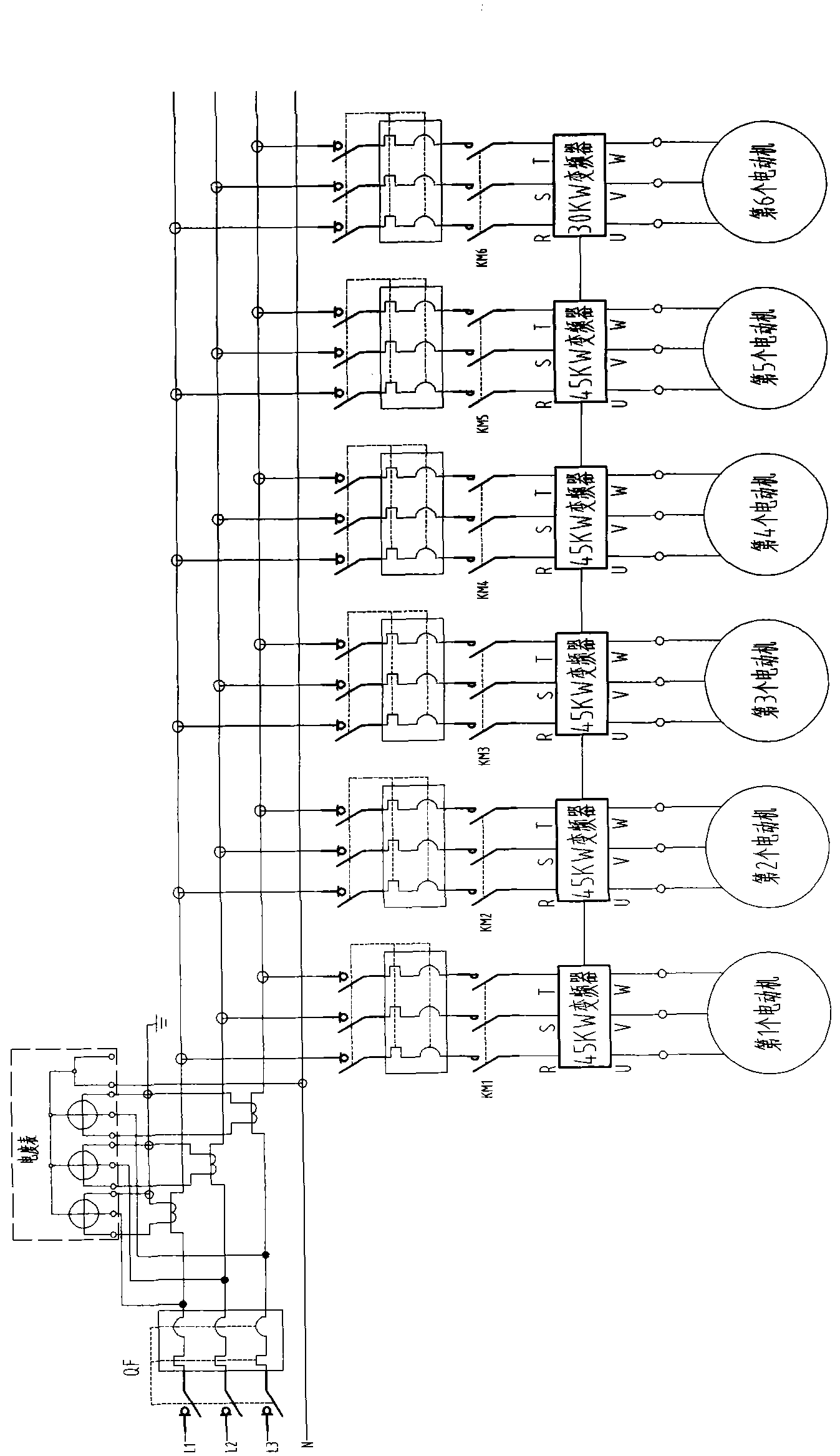

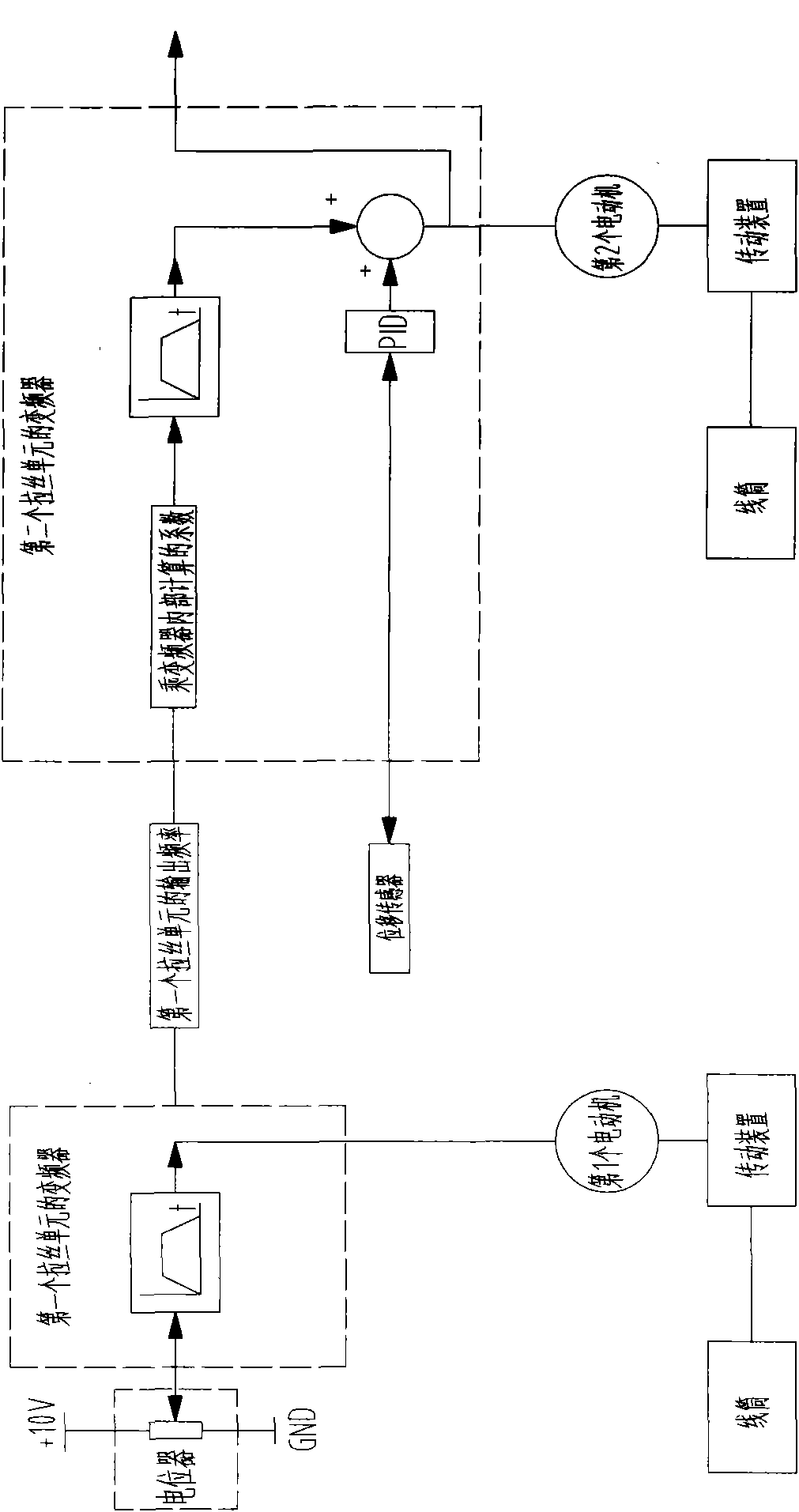

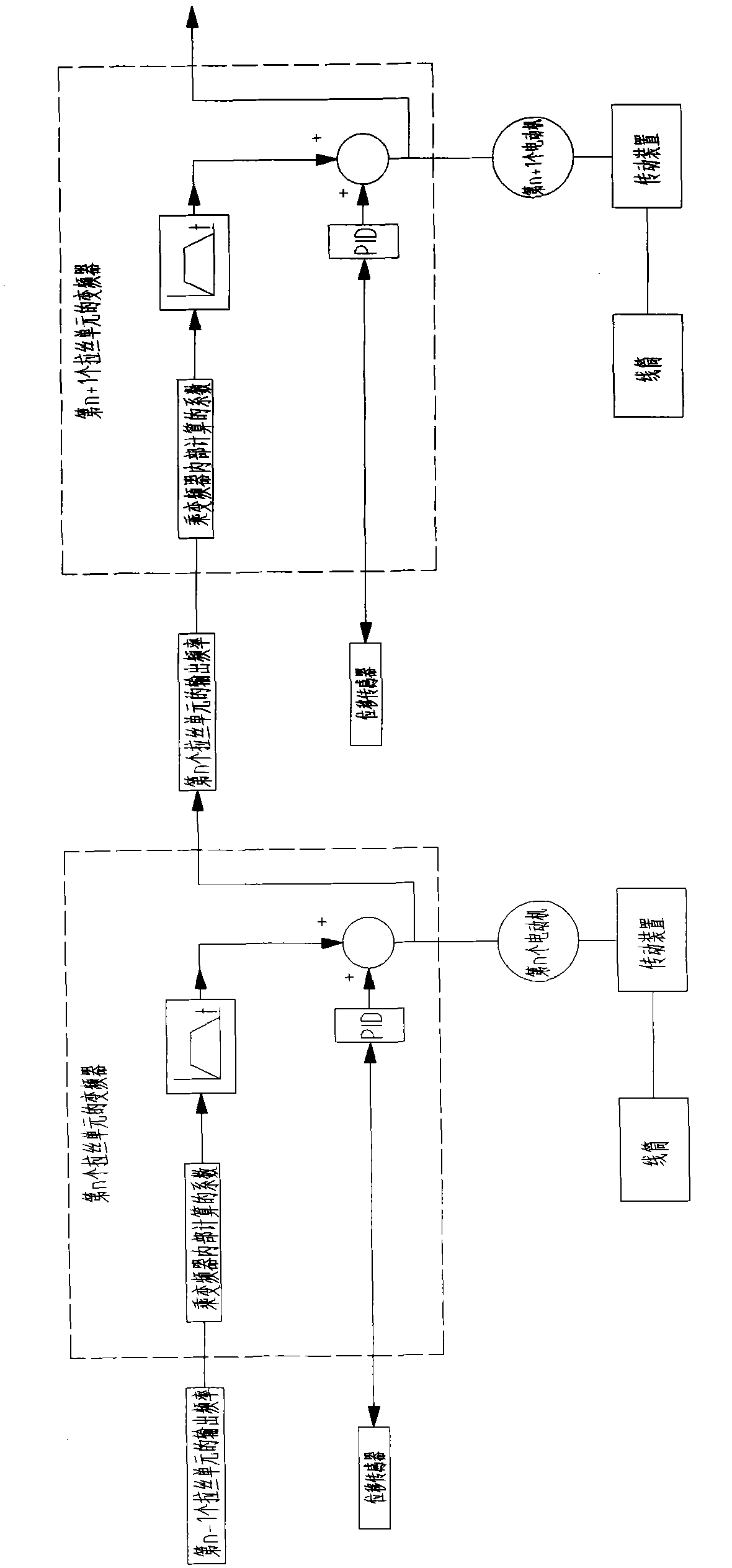

[0032] as attached Figures 1 to 7 As shown, a straight wire drawing machine system includes a PLC, two or more wire drawing units, the wire drawing unit includes a frequency converter, a motor, a transmission device and a bobbin, and a tension is set between two adjacent wire drawing units. As for the detection device, an operation program is stored inside the frequency converter, and the operation steps of the operation program include:

[0033] Let n be the sequence number of the wire drawing unit, n be a non-zero natural number, the output frequency f of the inverter of the n+1th wire drawing unit n+1 Calculations include;

[0034] A) Obtain fine-tuning correction coefficient k 0 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com