Floor block connecting structure and floor block adopting the same

A technology for connecting structures and floor plates, applied in building structures, floors, buildings, etc., can solve problems such as the difficulty of ensuring the strength of the slot or tongue, affecting the aesthetic effect of splicing, and difficult splicing structures, etc. Achieve the effect of improving assembly accuracy and connection strength, strong aesthetics and good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

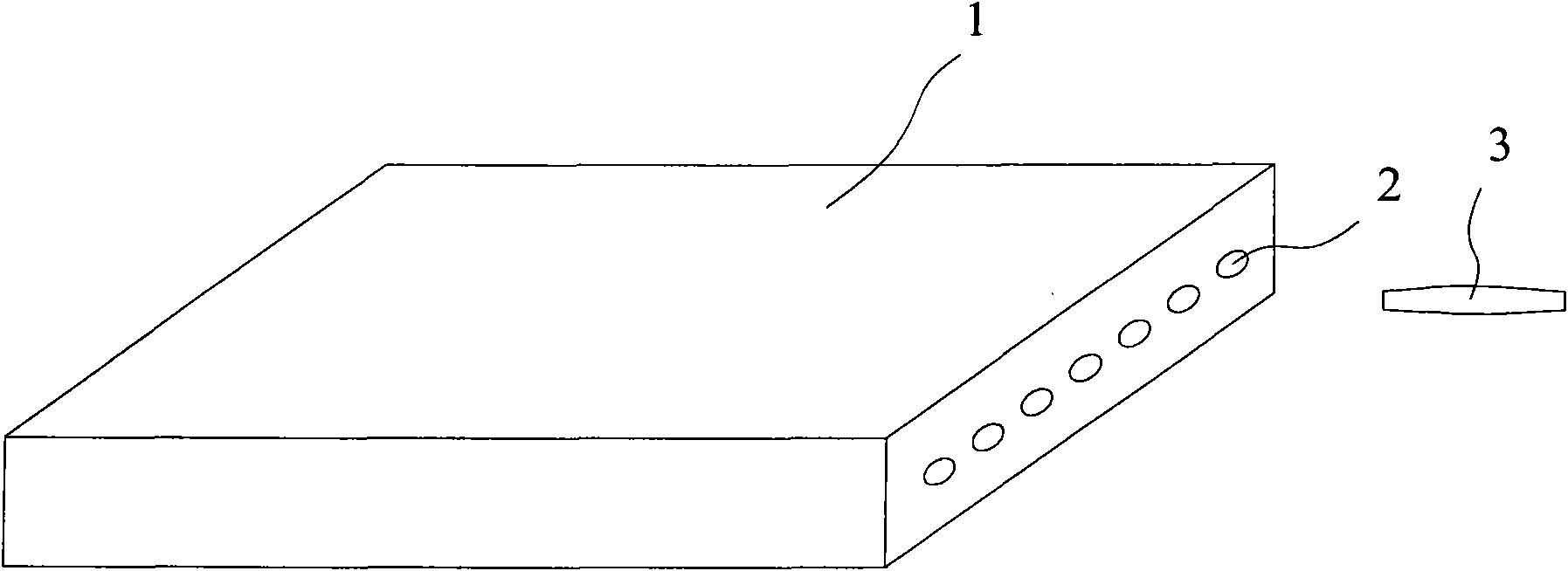

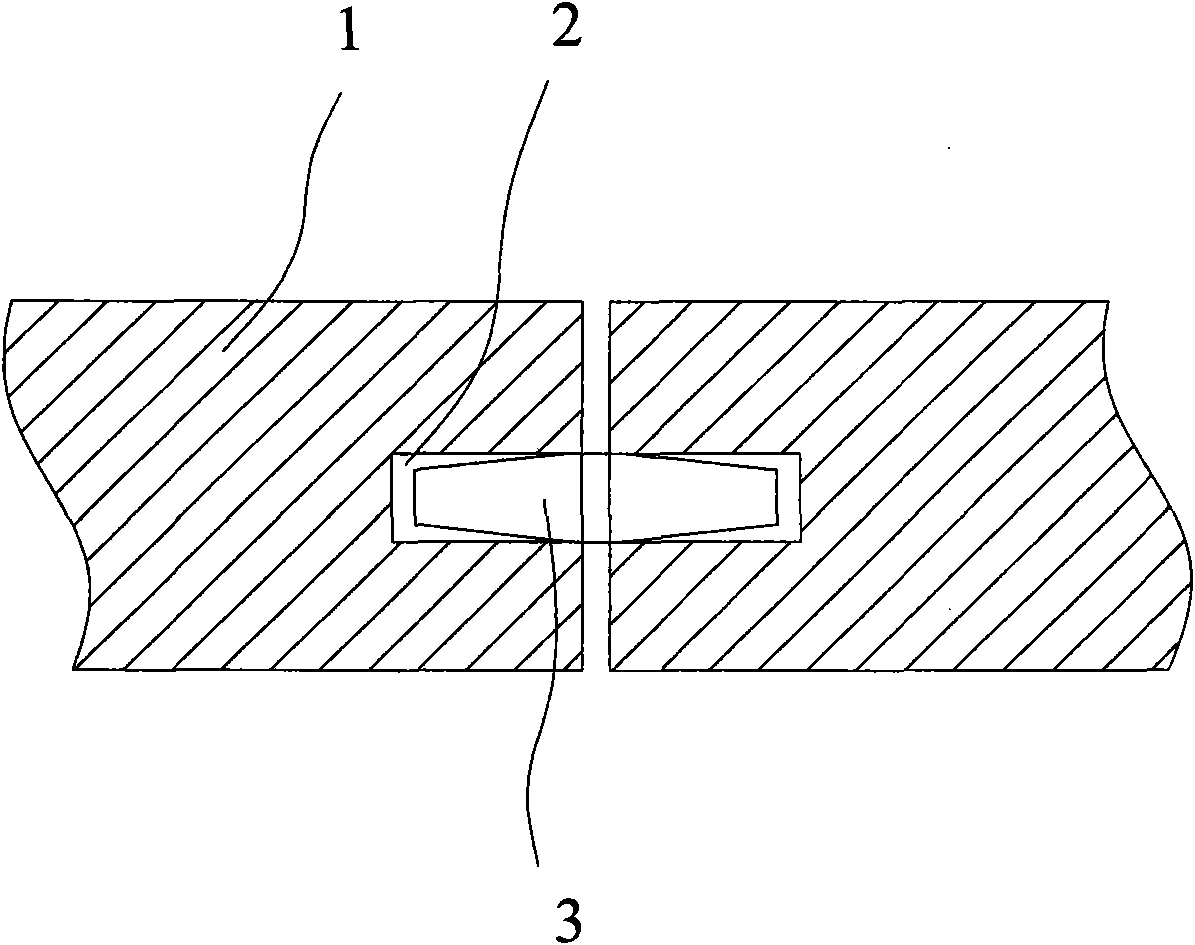

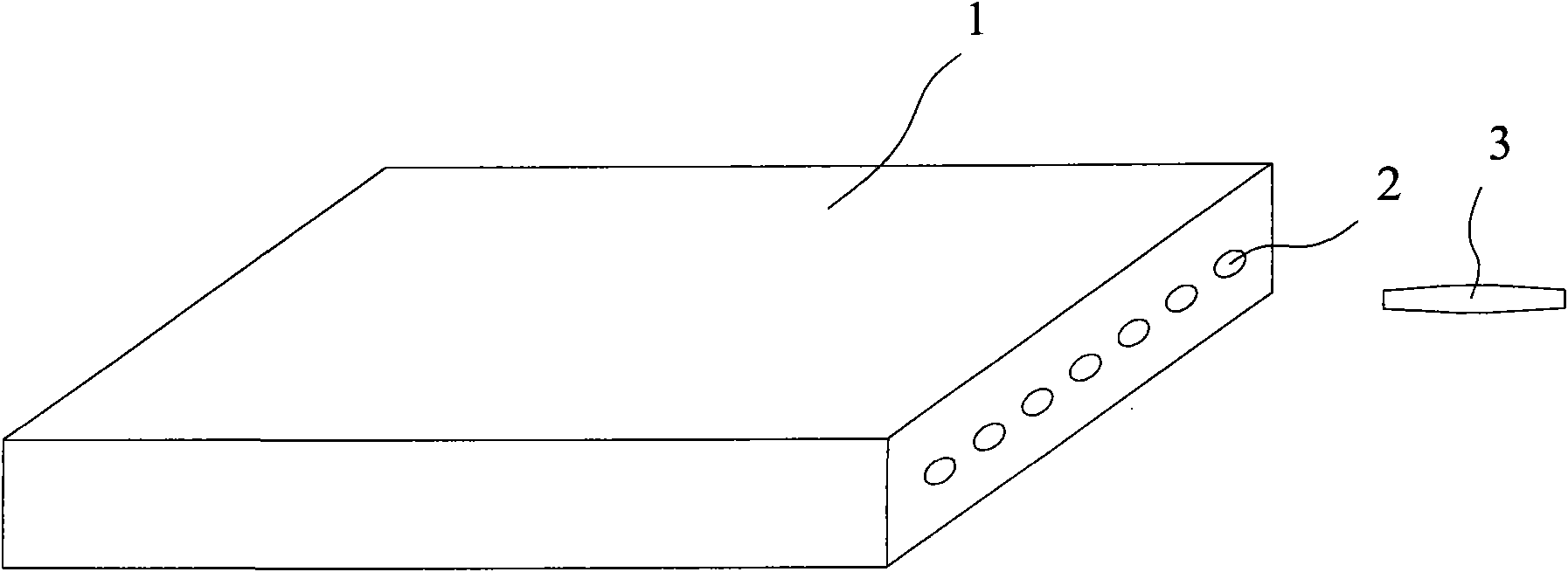

[0026] Such as figure 1 As shown, the splicing structure of the present invention includes: blind holes 2 arranged on the side of the floor body 1 and distributed along the length direction of the side, and wooden tenon strips 3 that can be inserted into and snapped into the blind holes 2 . Both ends of the tenon strip 3 have tapered sections of appropriate length, which facilitates the insertion of the tenon strip 3 into the blind hole 2 and can be firmly snapped into the blind hole 2 after insertion. The blind hole 2 can be a square hole or a round hole, and the cross section of the dowel bar 3 can be a square or a circle that matches the shape of the cross section of the blind hole 2 .

[0027] Because the present invention adopts the structure in which the tenon strip 3 is inserted into the blind hole 2, the processing of the blind hole 2 is faster and more convenient than the processing of the slot, and the processing of the tenon strip 3 can also be processed separately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com