Heating systems for hydrogen storage materials

A technology for storage materials and heaters, which is applied in the field of hydrogen storage and delivery systems, and can solve problems such as the efficiency limitation of electric heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

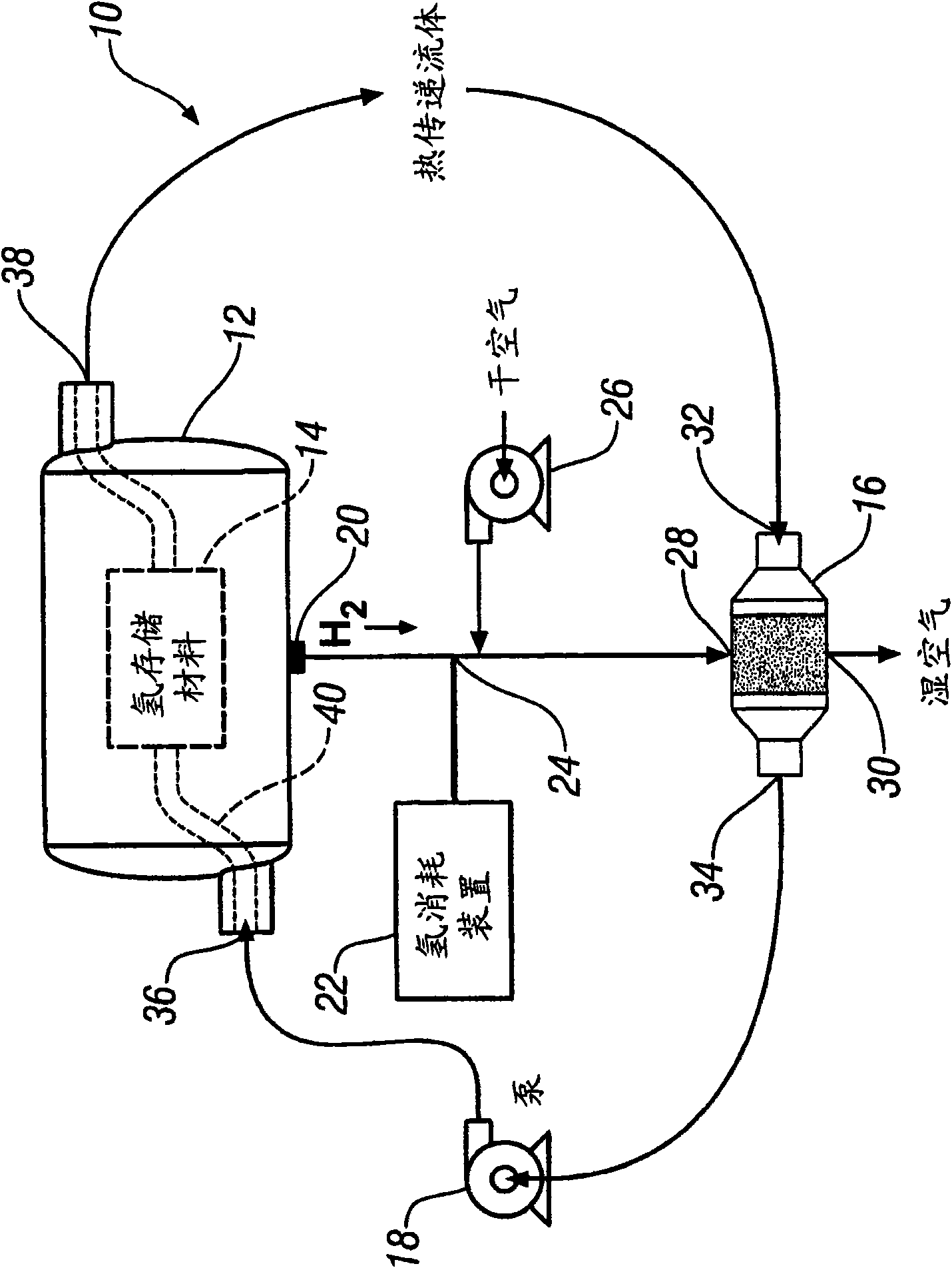

Example 1 - Catalytic Heater (Indirect Heating)

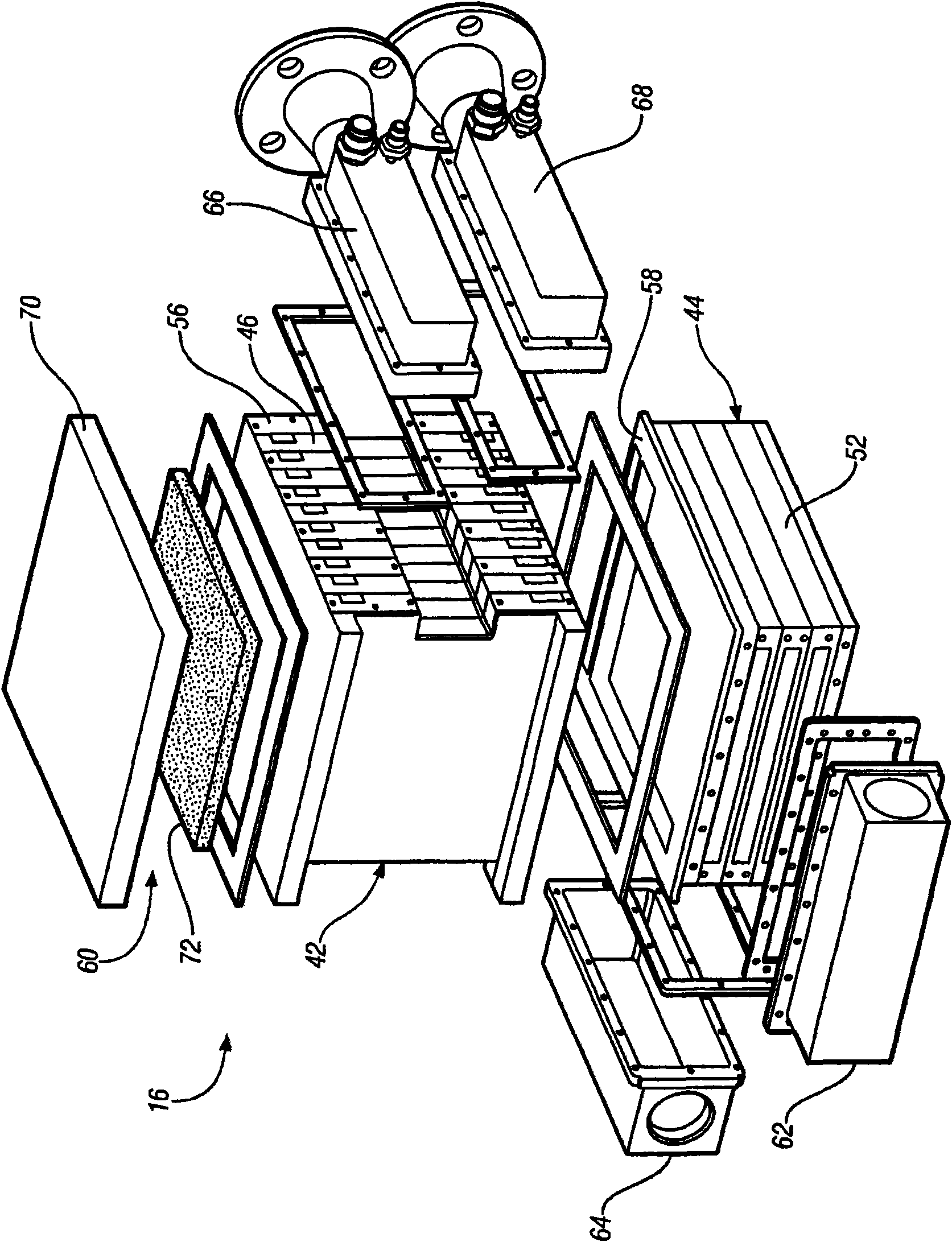

[0063] Specific embodiments of the catalytic heater 16' have been provided, used herein with Figure 1-3 Corresponding primary numerals in like reference numerals denote that it is capable of transferring more than 30 KW of heat from the catalytic combustion of hydrogen and oxygen to the heat transfer fluid. The size, shape and configuration of the reactor 42' and gas heat exchanger 44' have been adjusted and optimized in an attempt to maximize heat transfer to the heat transfer fluid while minimizing the mass and volume of the catalytic heater 16'.

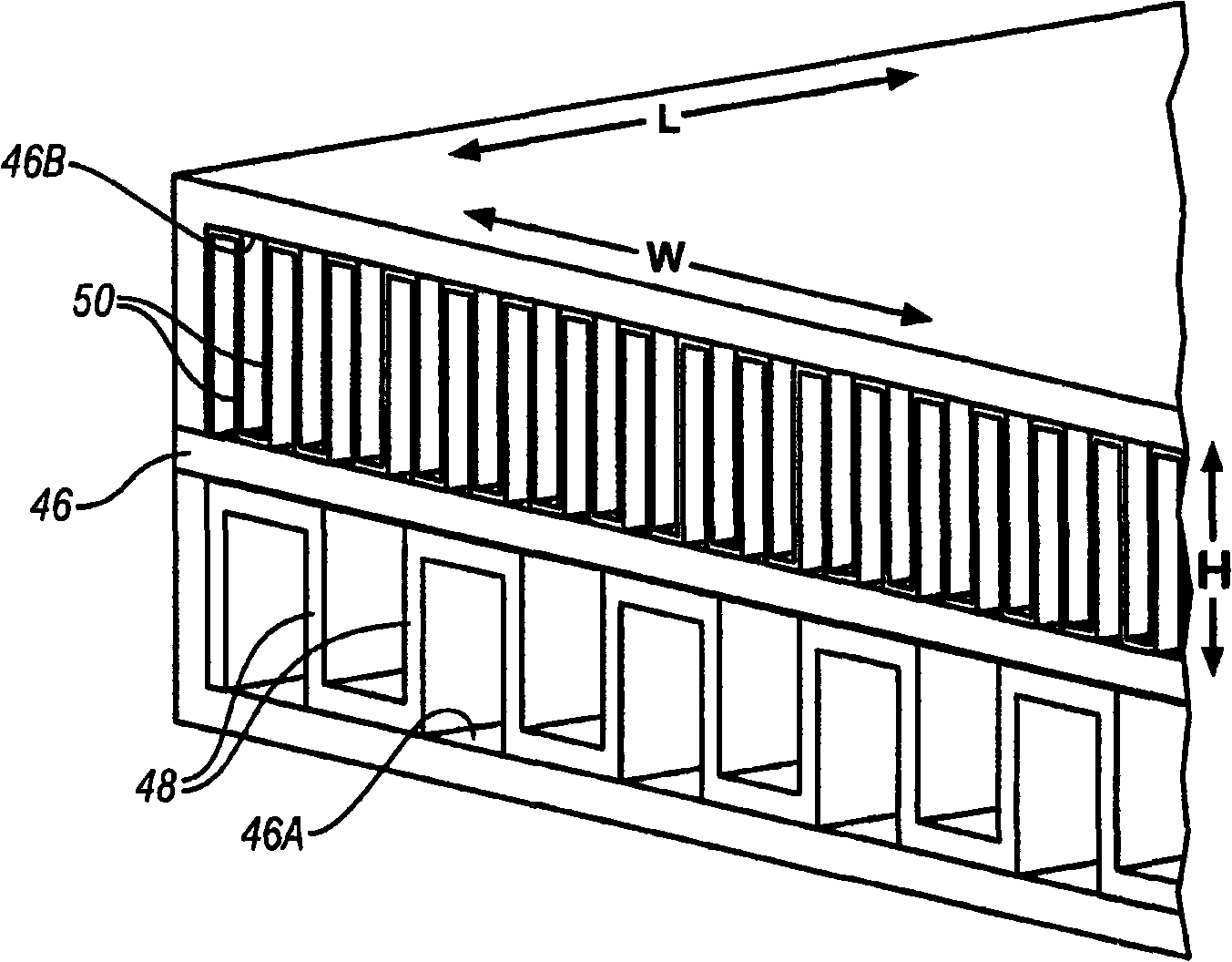

[0064] In this embodiment, the reactor 42' comprises a Figure 2-3 Ten heat transfer layers 46' are shown and similar to those described. Ten layers 46' are brazed together to form alternating and parallel gas flow channels 46A' and liquid flow channels 46B' which allow co-current flow. Each of the layers 46' has a length L (along which the reactant gas mixture and heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com