Flooded water-source heat pump unit with refrigerant side cold and heat reversion

A technology of water source heat pump unit and refrigerant side, which is applied in the direction of refrigerator, refrigeration and liquefaction, and compressor with reversible cycle, etc. It can solve the problems of complex water system piping, increased unit cost, and large room space, and achieve water The system is simple, the efficiency is improved, and the effect of eliminating pollution

Active Publication Date: 2010-10-06

BEIJING ZHONGKE HUAYU HEAT PUMP EQUIP MFG

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, switch valves and pipelines need to be installed on both the use side and the cold and heat source side, resulting in complicated water system pipelines, cumbersome operations, and a large space required for the machine room

When the cold and heat source is a corrosive medium, both the evaporator and the condenser need to be made of anti-corrosion structure, resulting in a substantial increase in the cost of the unit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

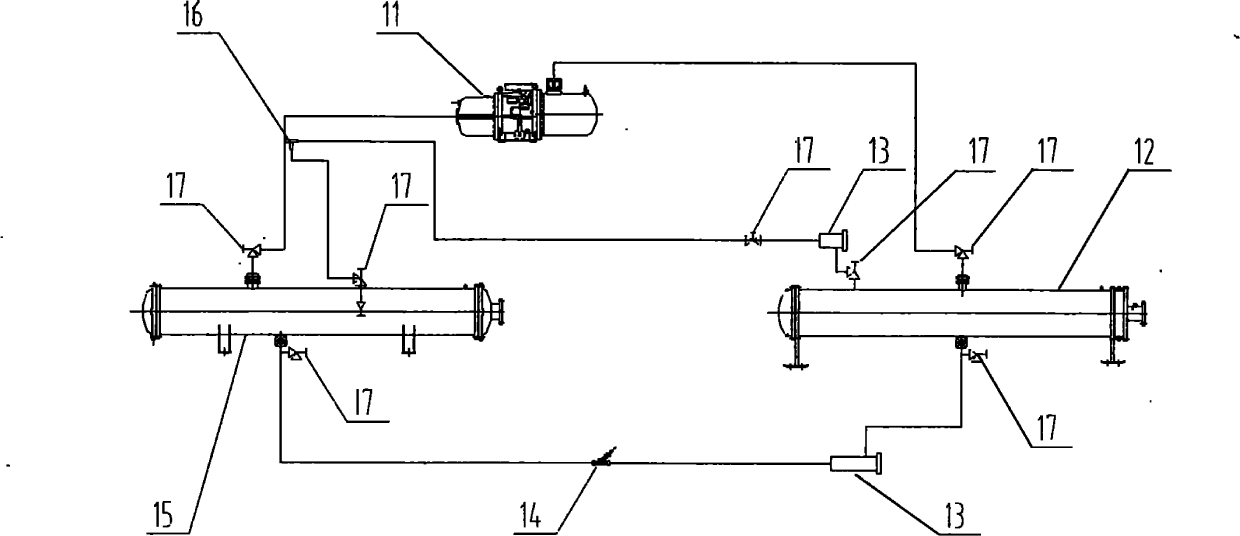

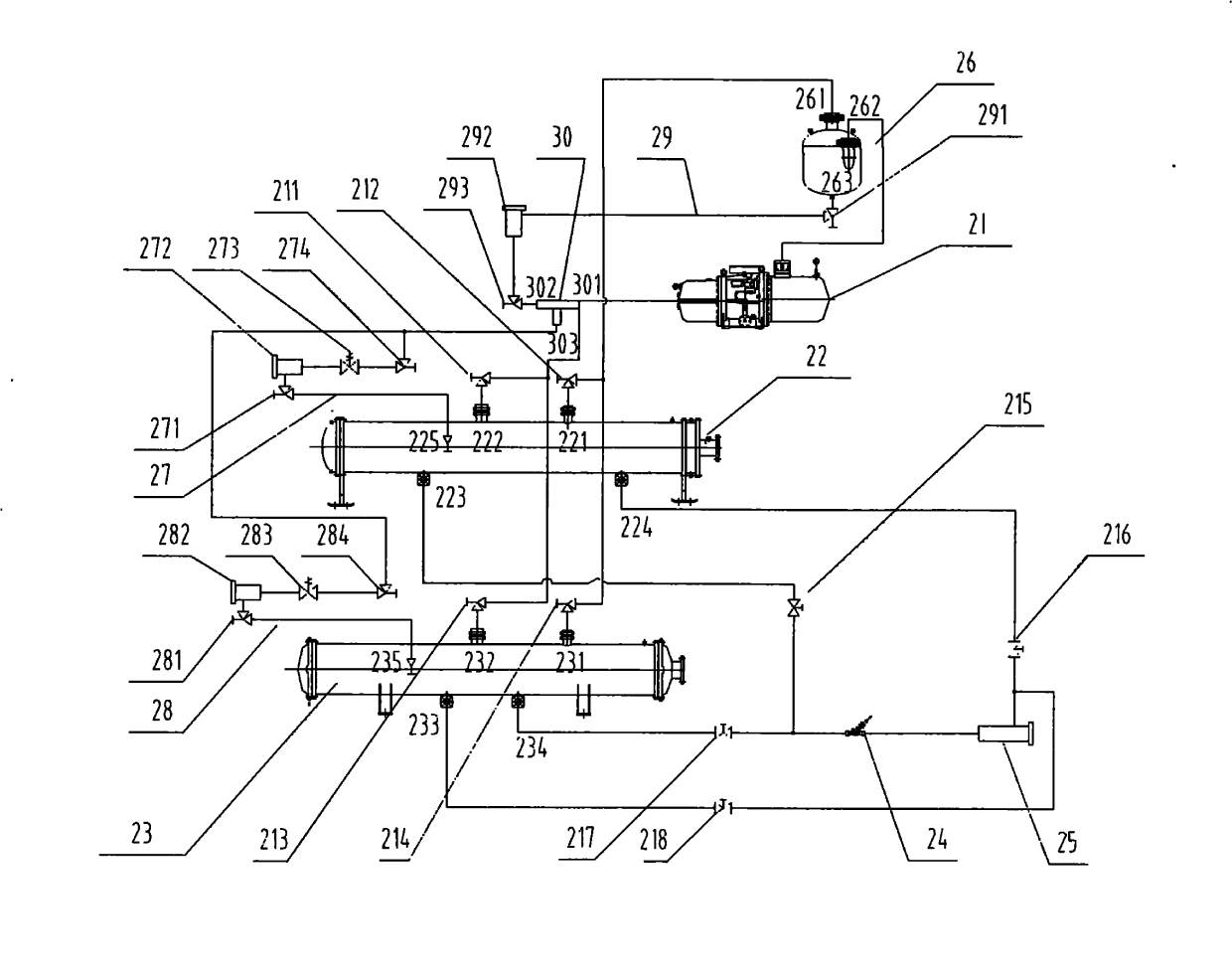

The invention relates to a flooded water-source heat pump unit with refrigerant side cold and heat reversion and belongs to the technical field of the water-source heat pumps. The unit comprises a compressor, a use side heat exchanger, a sewage side heat exchanger, a throttle valve, a filter, an oil separator and a plurality of valves, wherein an outlet of the compressor is connected with an inlet of the oil separator; an outlet of the oil separator is connected with a first opening on the top of the use side heat exchanger and is also connected with a first opening on the top of the sewage side heat exchanger; an inlet of the compressor is connected with a second opening on the top of the use side heat exchanger and is also connected with a second opening on the top of the sewage side heat exchanger; a first path of opening on the bottom of the use side heat exchanger is connected with an inlet end of the filter; an outlet end of the filter is connected with an inlet of the throttle valve; a second path of opening on the bottom of the use side heat exchanger is connected with an outlet of the throttle valve; a first path of opening on the bottom of the sewage side heat exchanger is connected with an inlet of the filter; and a second path of opening of the sewage side heat exchanger is connected with the outlet of the throttle valve. The unit simplifies a pipeline of a machine room and is convenient to operate and maintain.

Description

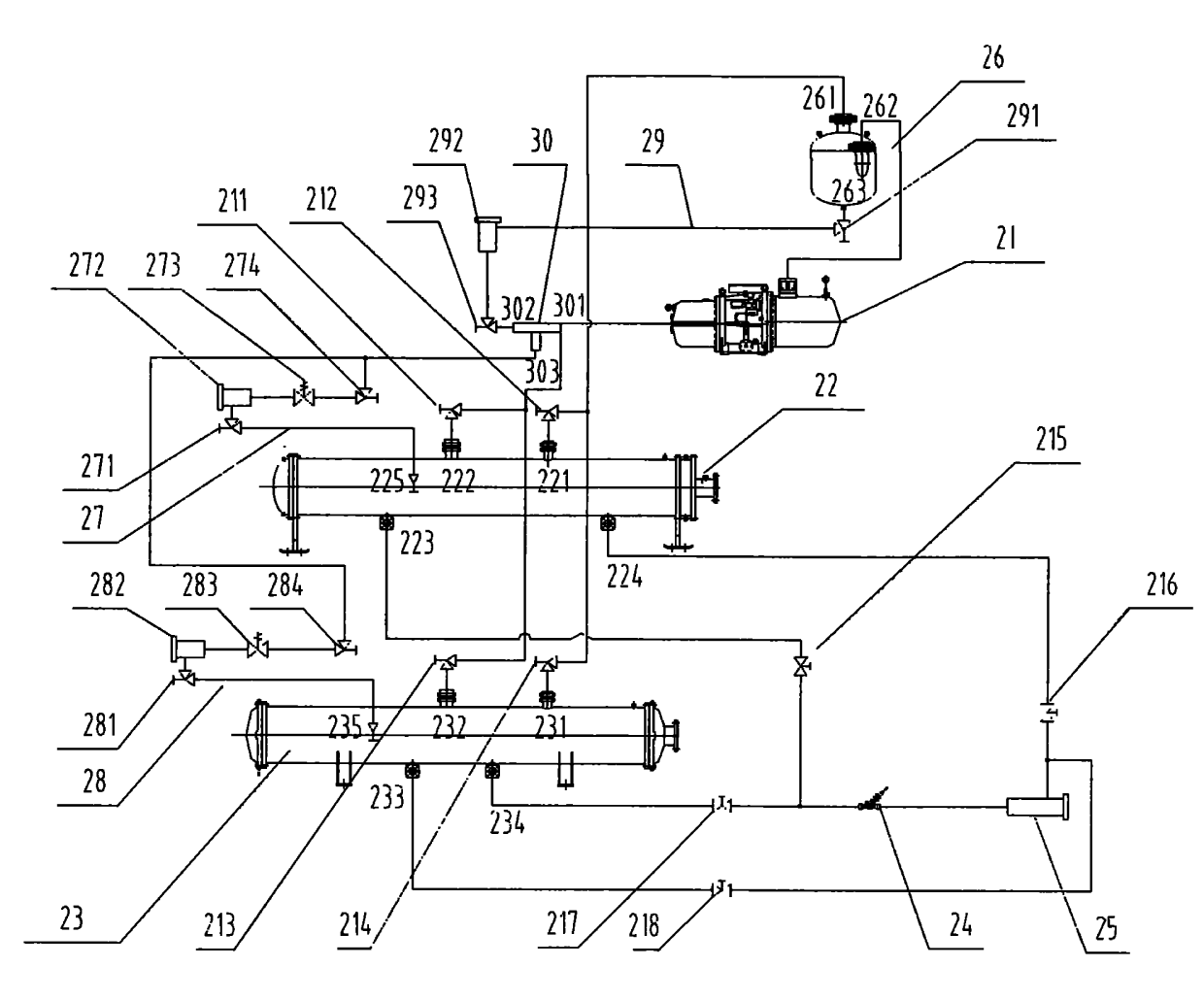

technical field The invention belongs to the technical field of water source heat pumps, in particular to a vapor compression flooded water source heat pump unit. Background technique The traditional flooded water source heat pump unit is the same as the flooded chiller in terms of refrigeration system composition. As shown in Figure 1, the unit is mainly composed of a compressor 11, a flooded evaporator 15, a water-cooled condenser 12 and a throttle valve 14, and is equipped with a valve 17 and a filter 13 to form a complete system; its connection relationship is : the outlet of the compressor 11 is connected to a valve 17, and then connected to the inlet of the water-cooled condenser 12, the outlet of the water-cooled condenser 12 is connected to a valve 17, then connected to the filter 13 and the throttle valve 14, and finally passed through a valve 17 It is connected with the inlet of the flooded evaporator 15, and the outlet of the flooded evaporator 15 is connected wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F25B13/00

Inventor 张军刘亚兵

Owner BEIJING ZHONGKE HUAYU HEAT PUMP EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com