Imaging ellipsometer based on magneto-optical effect

An imaging ellipsometer, magneto-optical effect technology, applied in the direction of surface/boundary effects, instruments, scientific instruments, etc., can solve the limitation of measurement accuracy control accuracy, limited measurement repeatability and stability, and limited ellipsometer measurement speed, etc. problem, to achieve the effect of improving measurement accuracy, high modulation accuracy, and fast modulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

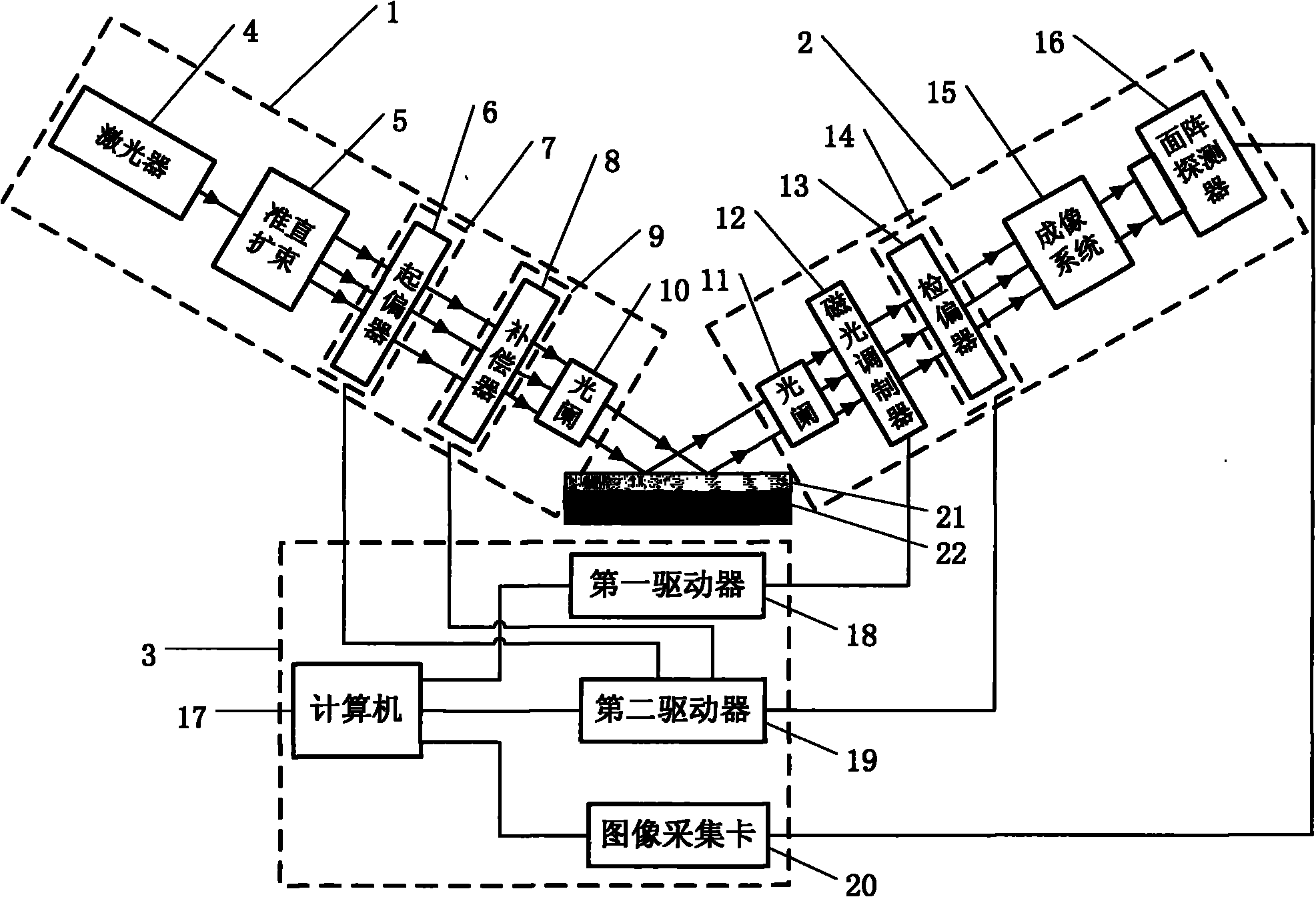

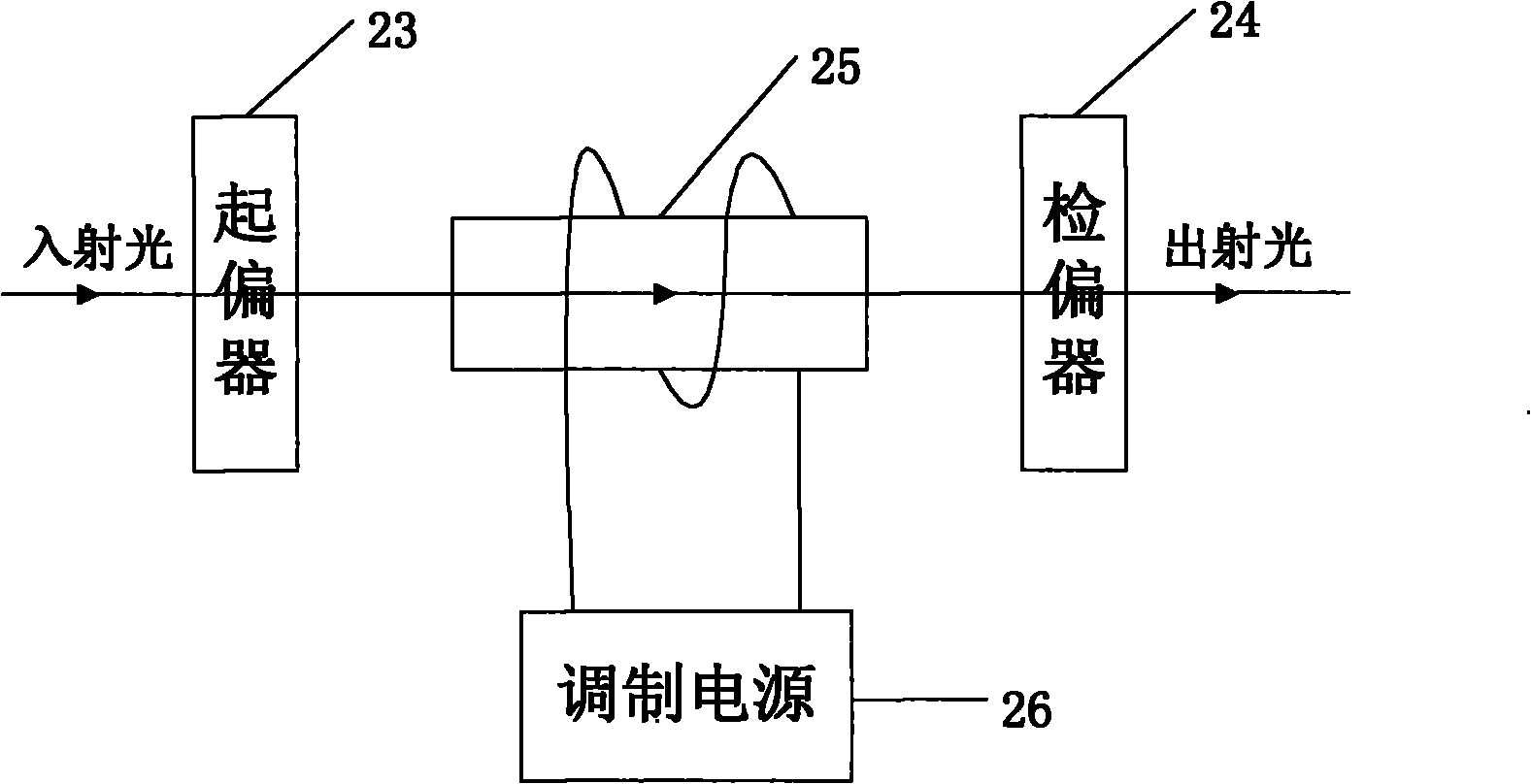

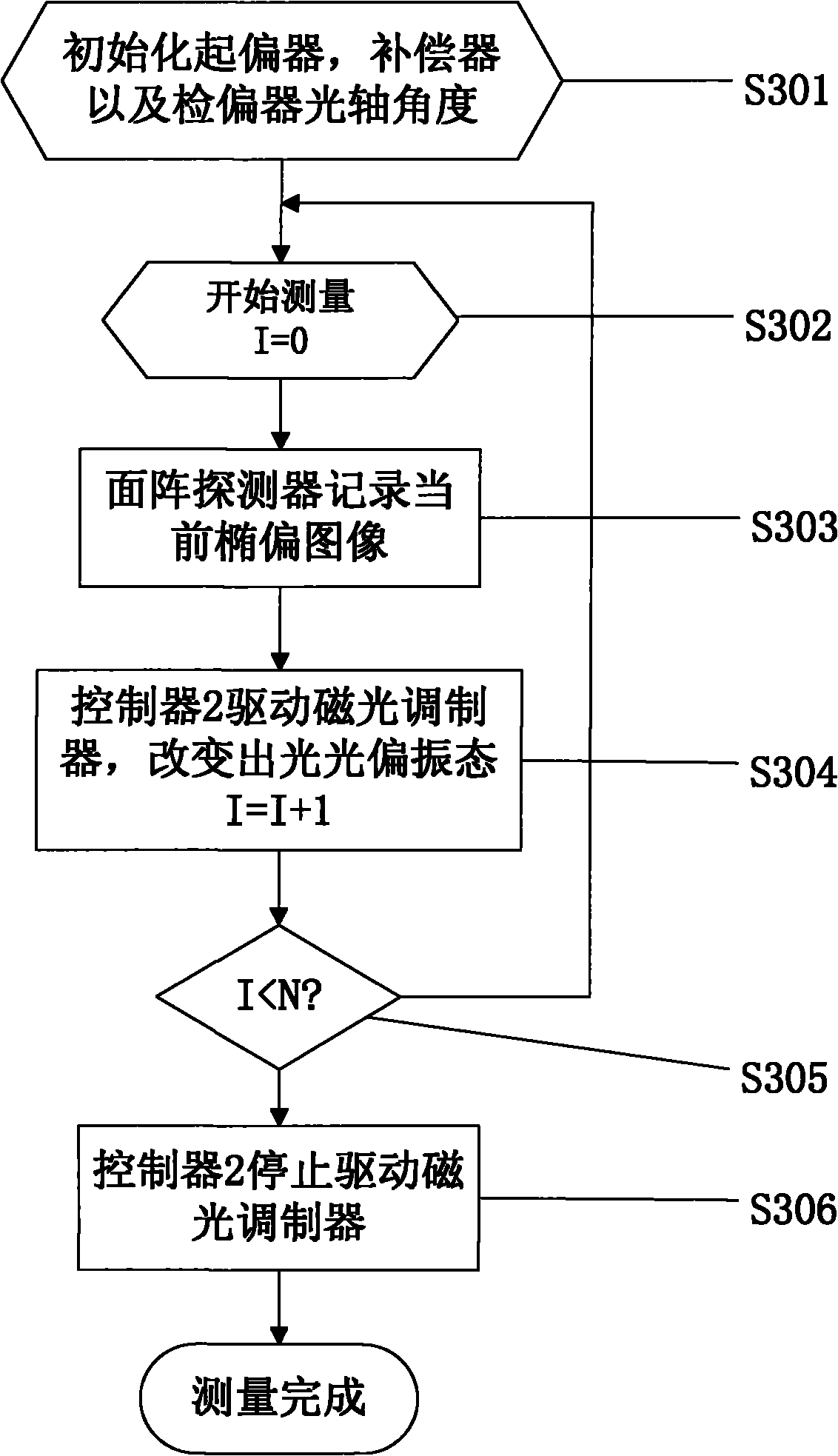

[0025] like figure 1 , 4 As shown in and 5, the present invention is characterized by comprising: an incident arm with polarization state and spot size control components, a receiving arm with polarization state and spot size control components, and a control system, wherein:

[0026] Incident arm (1) with polarization state and spot size control components, including: light source (3), collimating beam expanding device (4), polarizer (5), rotating console (6), compensator (7) ), rotating console (8), entrance diaphragm (10), where:

[0027] a light source (3) for emitting single-frequency light for illuminating the object to be measured;

[0028] a collimating beam expanding device (4) for collimating and expanding the laser beam emitted by the laser (3), so that the outgoing light becomes parallel light;

[0029] a polarizer (6) for converting parallel light of any polarization state into linearly polarized parallel light;

[0030] A rotating console (7) is used to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com