Method for testing resolution of each imaging region of digital camera

An imaging area, digital camera technology, applied in the field of image processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1 Canon EF 28-135 image quality test at F8.0 at 135mm

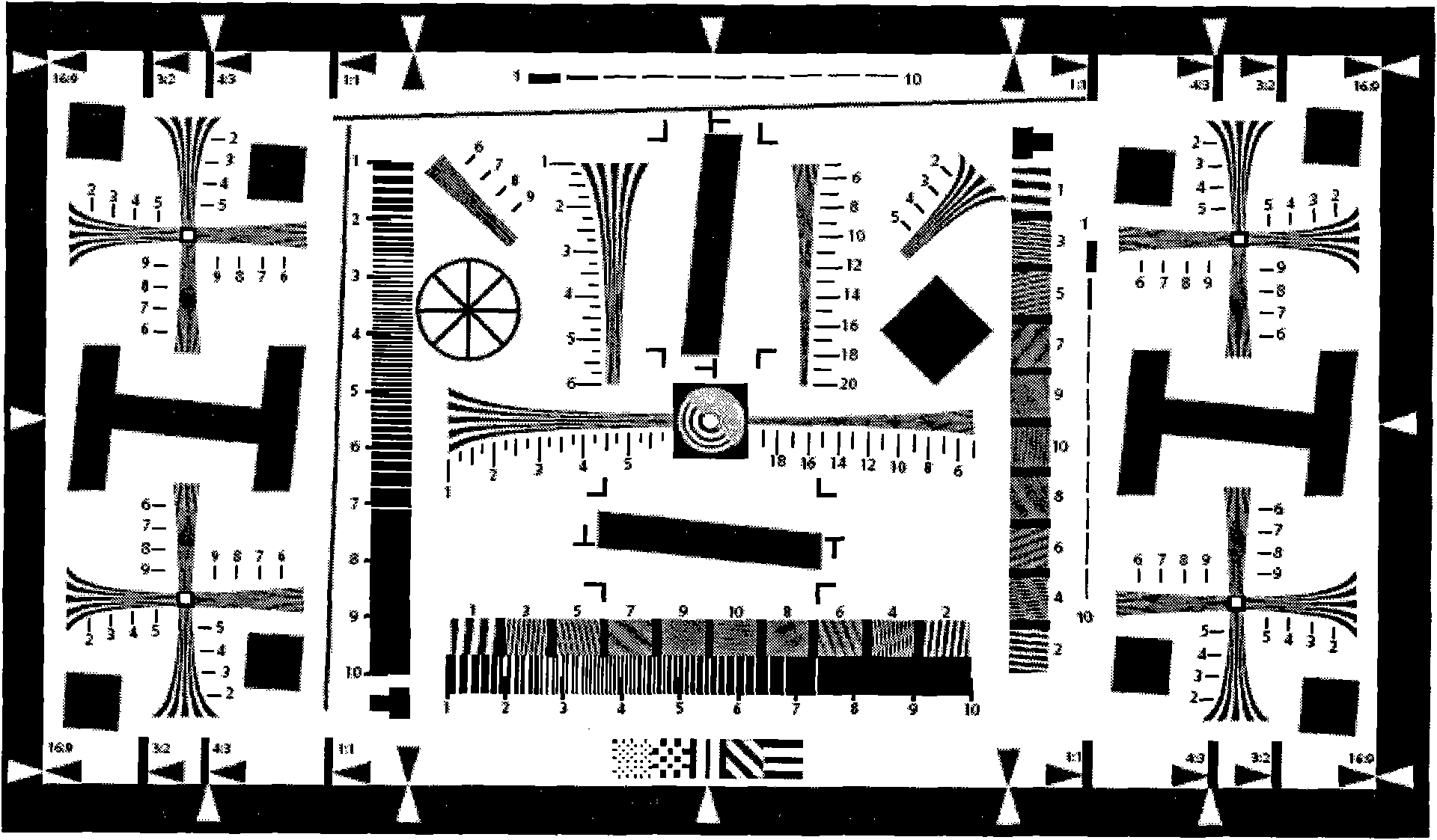

[0085] First prepare the resolution test board. The test board ( image 3 ) directly displayed on a monitor or a projector, or printed out and pasted on a glass or plastic plate. image 3Each white dot in is a pixel, and the interval between white dots is 5 pixels (of course, the interval can also be larger or smaller). Then if it is displayed on a 30-inch monitor (DELL 3008WFP), there are a total of 2560×1600 pixels and about 512×320 white points. The use of monitors is mainly from the perspective of cost and convenience, because there are already high-resolution monitors. In fact, if you print a 30-inch screen, the cost is relatively high, and the mounting is also troublesome. Glass or plastic boards also cost money. If a high-resolution monitor is not readily available, it can also be printed and shot for testing.

[0086] The second is to shoot. Use a tripod to set up the camera Canon 1Ds Mark III, ...

Embodiment 2

[0114] Example 2 Canon EF 100-400L imaging quality test at F8.0 at 135mm

[0115] Adopt the test method of embodiment 1.

[0116] Figure 11a and Figure 11b The results of the edge and the center are given respectively. Although there is a certain amount of astigmatism and dispersion, it is not obvious. You can compare it with Figure 5.

[0117] Figure 12 The measurement results of the astigmatism are given, and as in Example 1, the radial astigmatism is obviously greater than the tangential one, so only the radial astigmatism needs to be considered. It can be seen that the average and maximum values of radial dispersion in the central part are around 5 and 7, respectively, and even at the outermost edge, the astigmatism is less than 1.5 times that in the central part. That said, the Edge is perfectly usable if the requirements aren't particularly demanding.

[0118] Figure 13 and Figure 14 The test results of relative astigmatism and resolution are given respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com