Method and device for multifocal holographic differential confocal super-long focus measurement

A differential confocal and measurement device technology, applied in the direction of testing optical performance, etc., to achieve the effect of reducing influence, improving measurement accuracy and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

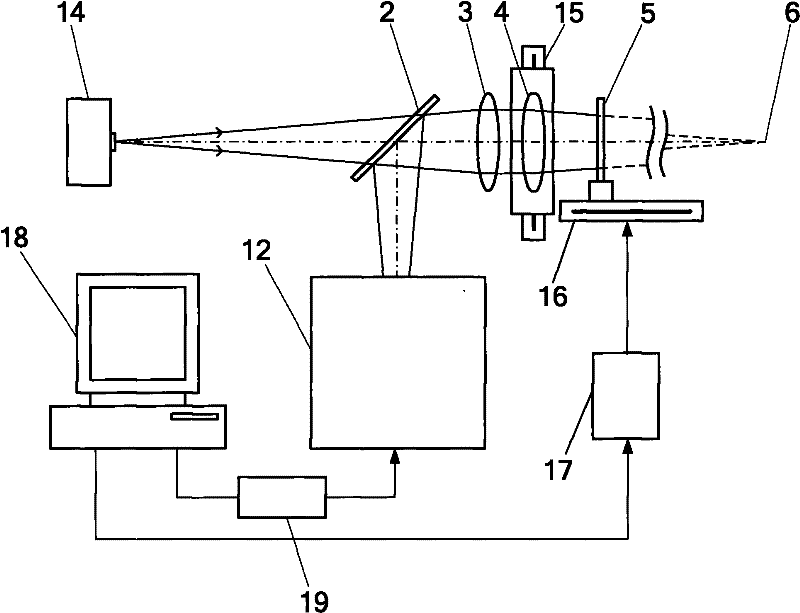

[0047] When the measured super long focal length lens 4 is a convex lens with a focal length of 10m, as Figure 7 As shown, the differential confocal ultra-long focal length measurement device, the measurement steps are:

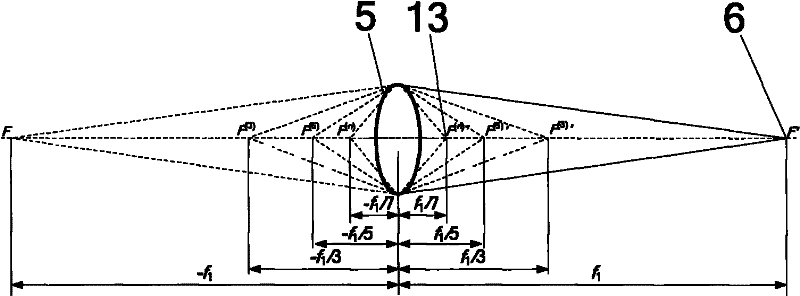

[0048] First, use the standard lens 28 with a focal length of 1200mm to calibrate the first-order focal length of the multi-focal holographic lens 5, as figure 2 As shown, it is known that the first-order focal length of the multifocal holographic lens 5 is f′ 1 , in addition to multiple higher-order foci, respectively at ±f′ 1 / 3, ±f' 1 / 5, ±f' 1 / 7, ±f' 1 / 9 and other positions, the focal length values corresponding to each focal point have a linear relationship. like Figure 8 As shown, the calibration steps are as follows:

[0049] (a) Start the measurement software in the main control computer 18, turn on the laser light source 24, and the laser light emitted by the laser light source 24 is transmitted through the optical fiber 23 to form a po...

Embodiment 2

[0063] When the measured ultra-long focal length lens 4 is a concave lens with a focal length of 10 m, the difference from Embodiment 1 is that the first-order focal length of the selected multi-focal holographic lens should be greater than 10 m. The calibration steps of the multi-focus holographic lens are the same as those in Embodiment 1. In the measurement step (c), the multifocal holographic lens is scanned along the optical axis, and the apex of the differential confocal light cone coincides with the negative first-order focus of the multifocal holographic lens by detecting the absolute zero point of the differential confocal response curve. The rest of the measurement steps are the same as in Example 1.

Embodiment 3

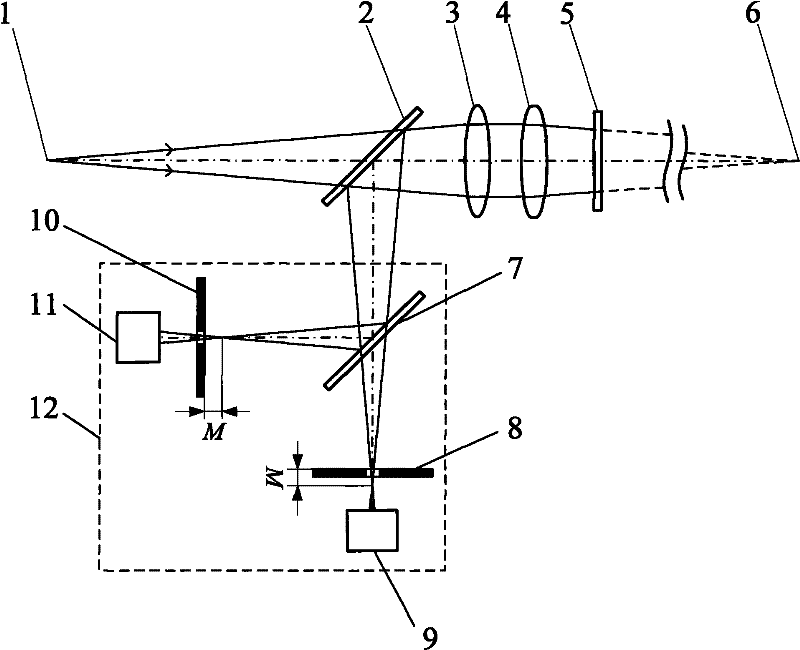

[0065] Different from Embodiment 1 or Embodiment 2, the differential confocal system 12 using pinhole detection can also be replaced by Figure 4 The shown direct detection differential confocal system includes the second beam splitter 7, the first light intensity sensor 9 and the second light intensity sensor 11; the light reflected by the first beam splitter 2 enters the differential confocal The focus system 12 divides the light into two paths by the second beam splitter 7, and one path is irradiated on the first light intensity sensor 9 located in front of the focus, and the other path is irradiated on the second light intensity sensor 11 positioned behind the focus; wherein the first The light intensity sensor 9 can be embodied as a CCD detector 25 , and the second light intensity sensor 11 can be embodied as a CCD detector 26 , and the subsequent measurement process is as described in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com