Method and apparatus for measuring cofocal combined ultra-long focal distance

A measurement method and a technology of a measurement device, which are applied in the direction of testing optical properties, etc., can solve problems such as ultra-long focal length fixed focus that have not yet been seen, and achieve the effects of reducing the length of the measurement optical path, reducing the impact, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

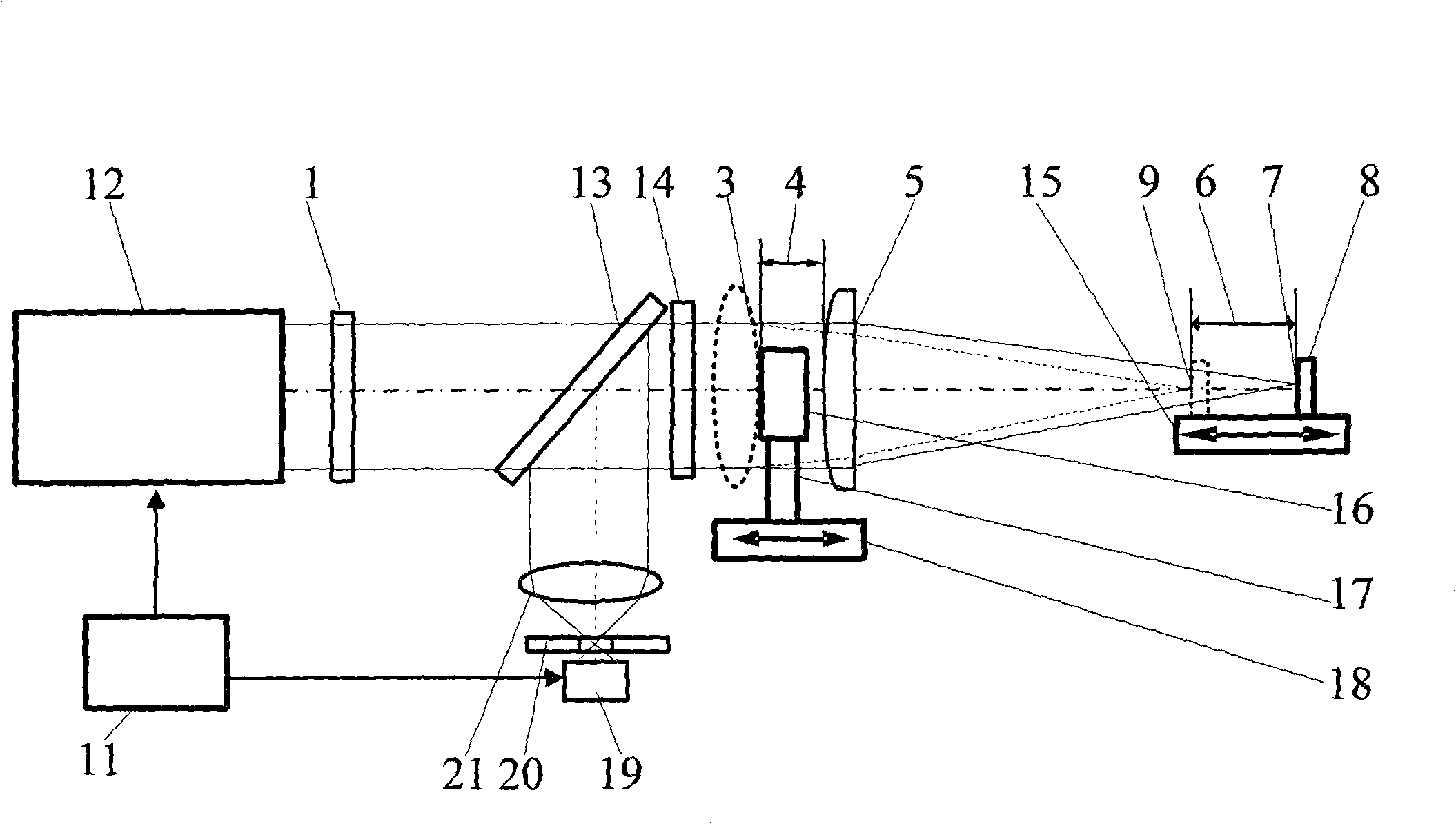

[0037] Such as image 3 As shown, a confocal combination ultra-long focal length measurement method, the measurement steps are:

[0038] First, turn on the light source 12, emit parallel light through the beam splitting system composed of the polarizing beam splitter 13 and the 1 / 4 wave plate 14, converge at the focus position a7 through the reference lens 5 with a focal length of 3000mm, and the light is reflected by the reflector 8 , enter the confocal fixed-focus system through 1 / 4 wave plate 14 and polarizing beam splitter 13 reflections; Converging lens 21 in the confocal fixed-focus system converges the light, and the convergent light passes through the pinhole 20 illumination CCD detector 19; 8 Scanning and moving along the translation stage a15 in the direction of the optical axis of the reference lens 5, the confocal fixed-focus system determines the corresponding focus position a7 of the reference lens by detecting the maximum point of the response signal of the CCD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com