Droplet break-up device

A technology of breaking device and droplet, applied in the direction of inking device, printing, etc., can solve the problem of difficult to achieve high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

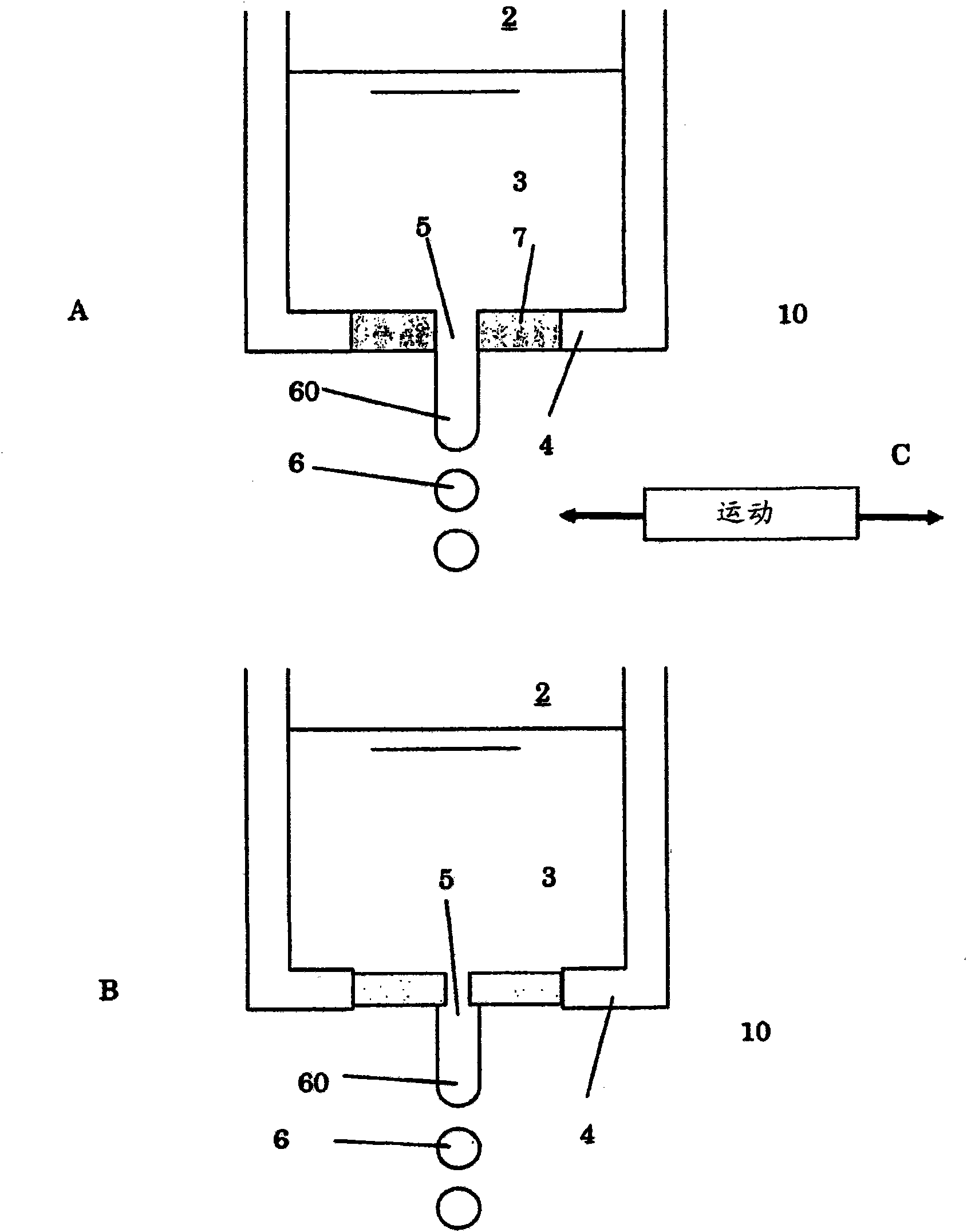

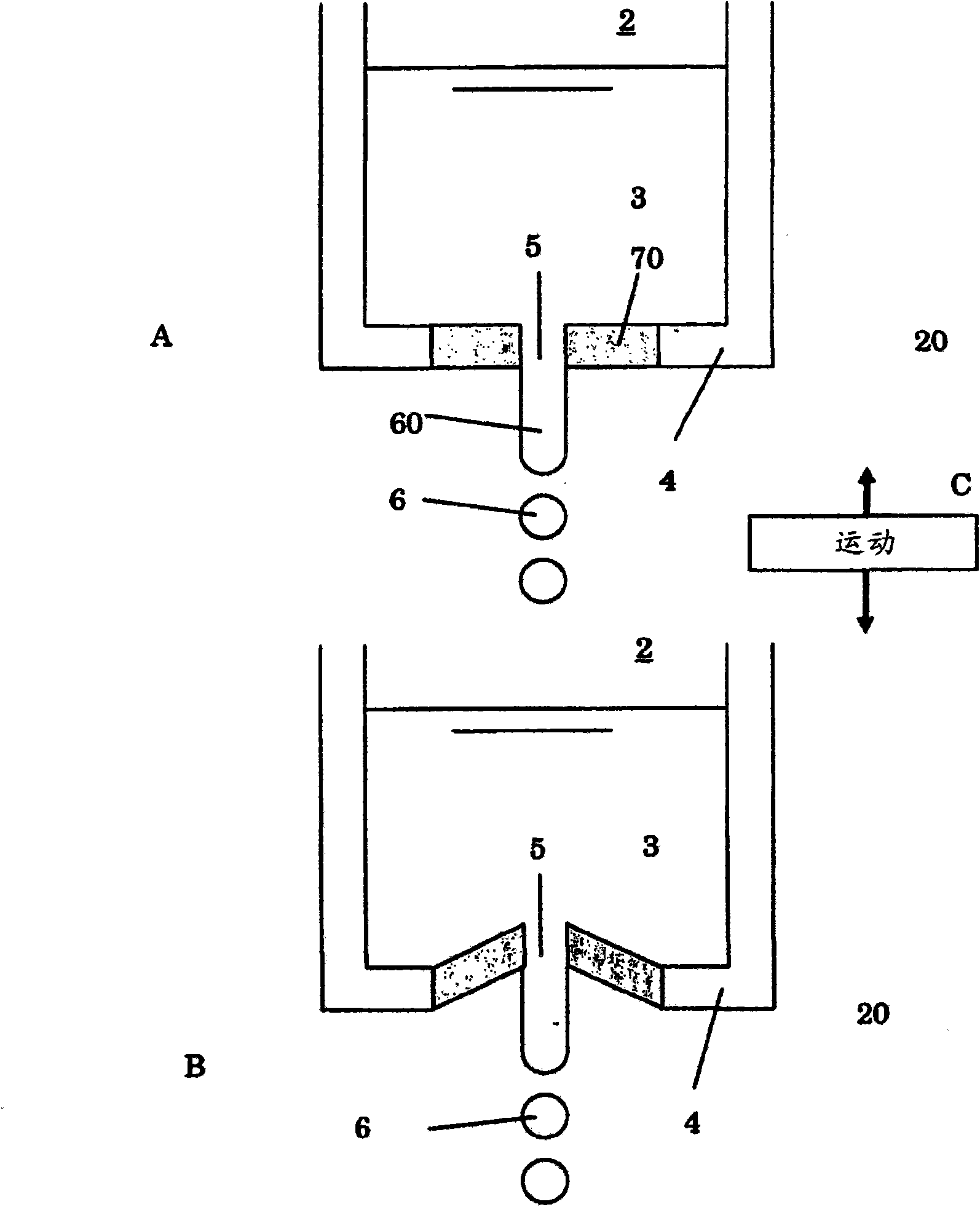

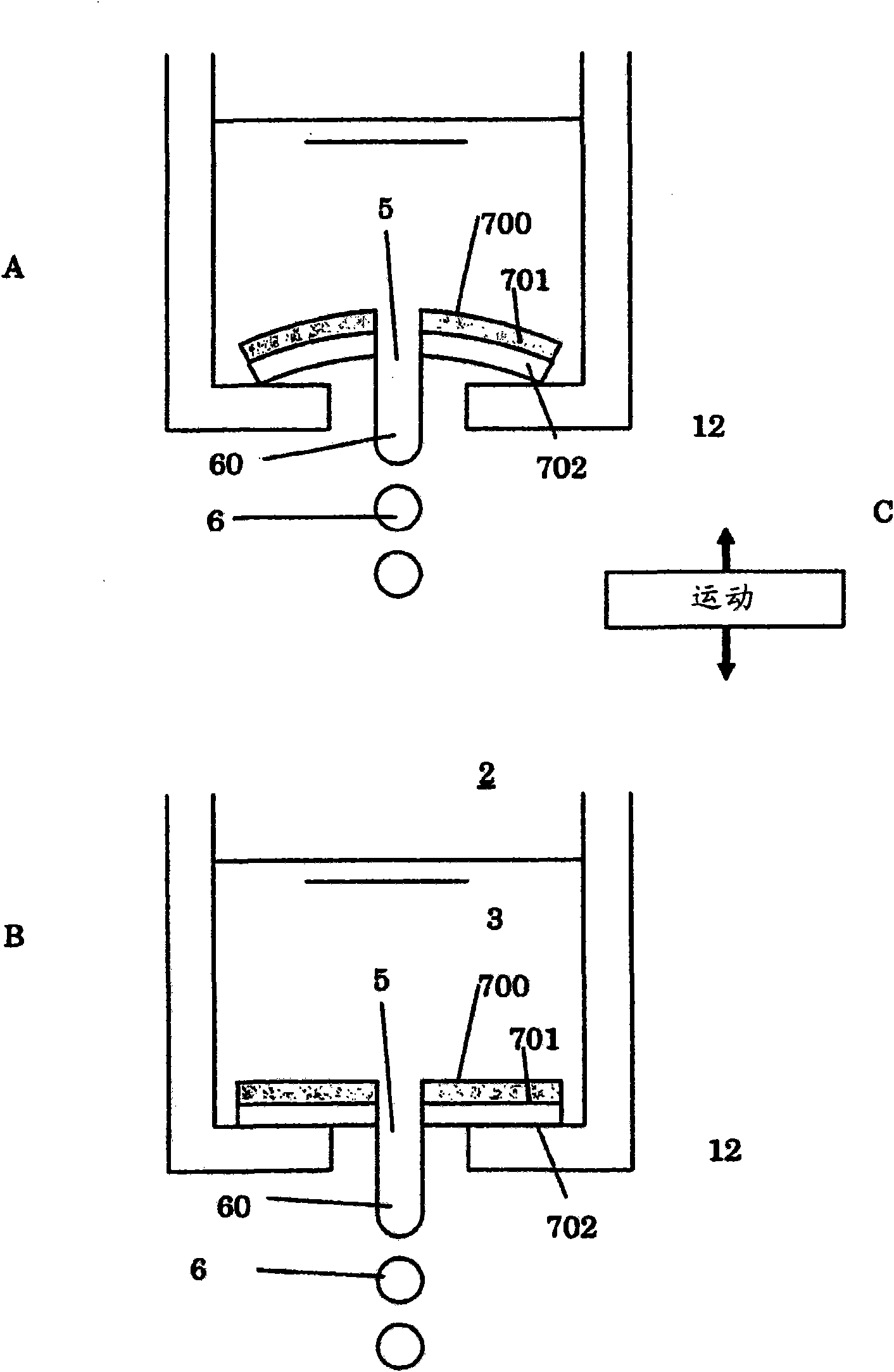

[0017] In the following, parts A, B and C represent the corresponding operating positions and actuating directions of the actuators.

[0018] figure 1 A first schematic embodiment of a droplet breaking device according to the invention is shown. In particular, drop break-off device (also referred to as printhead) 10 comprises a chamber 2 comprising a base plate 4 . The chamber 2 is adapted to contain a liquid 3 under pressure, for example by a pump or by a pressurized supply (not shown). The chamber 2 comprises an outlet duct 5 through which a pressurized fluid jet 60 is broken into droplets 6 . The outlet tube defines a central axis and around the outlet tube an actuator 7 is formed and substantially symmetrical with respect to the central axis of the outlet tube 5 . The actuator is preferably a piezoelectric element or a magnetostrictive element in the form of an annular disk arranged in the bottom plate 4 . By actuation of the actuator 7 a pressure pulse is formed which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com