High-precision piezoelectric sensor

A piezoelectric sensor, high-precision technology, applied in the field of sensors, can solve the problems of reducing the frequency range of device use, increasing the size and quality of components, and overlapping the center of mass of the central column, so as to avoid mass eccentricity, improve uniformity, reduce small impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

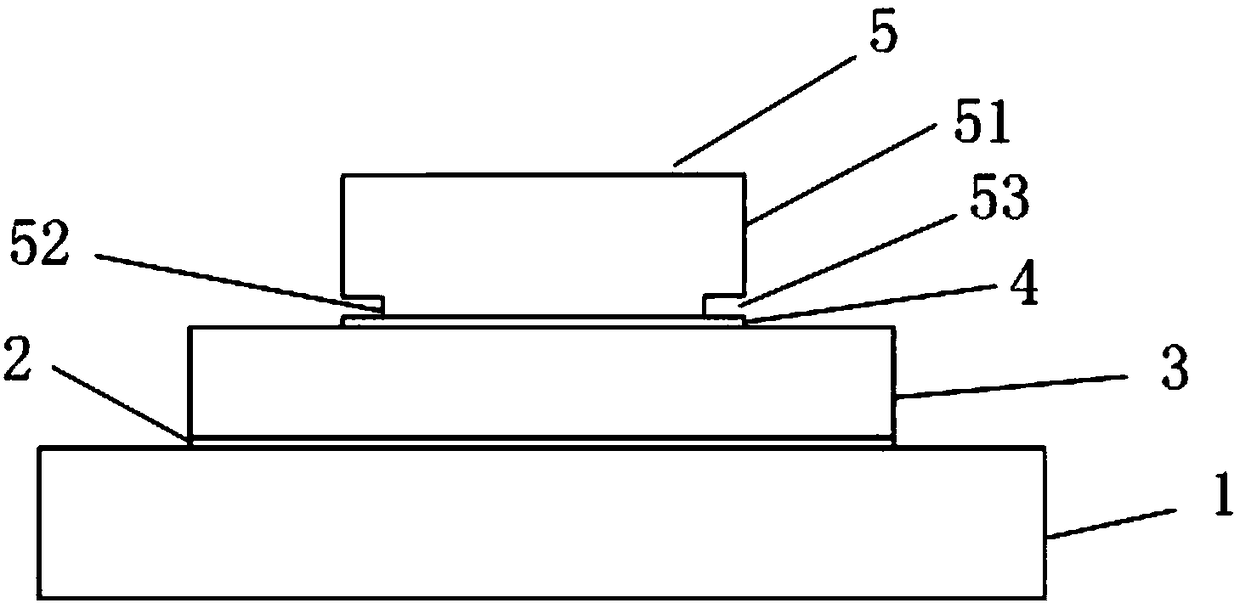

[0058] A high-precision piezoelectric sensor, such as figure 2 As shown, including a base 1, a first adhesive layer 2, a piezoelectric film layer 3, a second adhesive layer 4 and a mass 5 arranged on the base 1 in sequence;

[0059] The mass block 5 includes a body 51, a raised portion 52 at the bottom of the body 51, and a vacant portion 53 at the edge of the raised portion 52, the raised portion 52 is located on the axis of the mass block 5, and the body 51 is Cylindrical, its diameter is 4mm, and its height is 2.8mm, and described protrusion 52 is cylindrical, and its diameter is 2.5mm, and its height is 0.2mm, and described mass block 5 is made of copper, tungsten or tungsten copper, and its The weight is 0.32g;

[0060] The piezoelectric film layer 3 includes a support body, a first electrode, a piezoelectric film and a second electrode arranged on the support body in sequence, wherein the first electrode and the second electrode are both made of Pt, and both Both have...

Embodiment 2

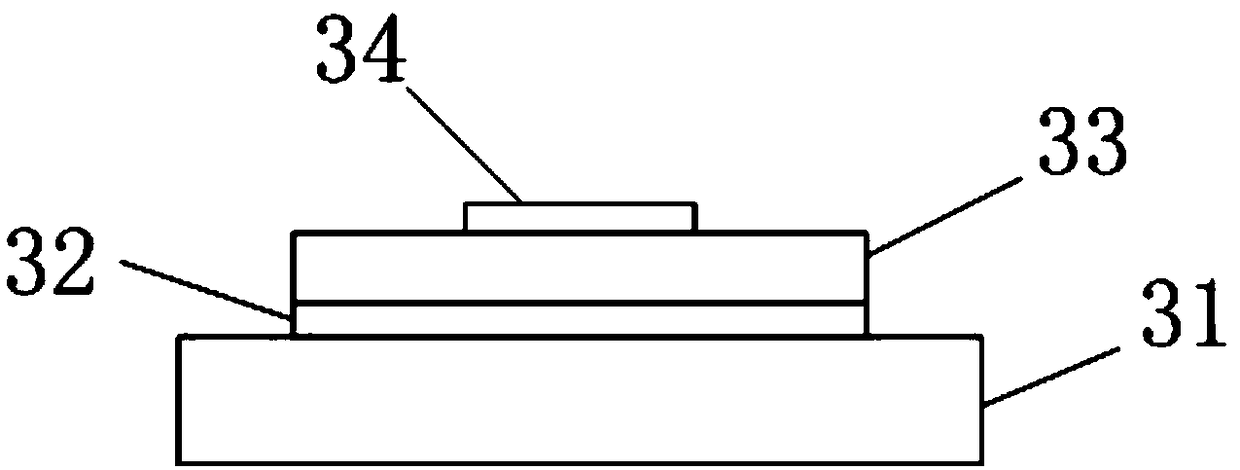

[0064] A high-precision piezoelectric sensor, such as Figure 5 As shown, including a base 1, a first adhesive layer 2, a piezoelectric film layer 3, a second adhesive layer 4 and a mass 5 arranged on the base 1 in sequence;

[0065] The mass block 5 includes a body 51, a raised portion 52 at the bottom of the body 51, and a vacant portion 53 at the edge of the raised portion 52, the raised portion 52 is located on the axis of the mass block 5, and the raised portion 52 includes a first raised portion 521 at the bottom of the body 51 and a second raised portion 522 at the bottom of the first raised portion 521, the body 51, the first raised portion 521 and the second raised portion 522 are all Cylindrical, the diameter of the body 51 is 4mm, the height is 2.8mm, the diameter of the first protrusion 521 is 3mm, the diameter of the second protrusion 522 is 1.5mm, and the mass block 5 is made of copper, tungsten or tungsten copper Made, its weight is 0.5g;

[0066] The piezoele...

Embodiment 3

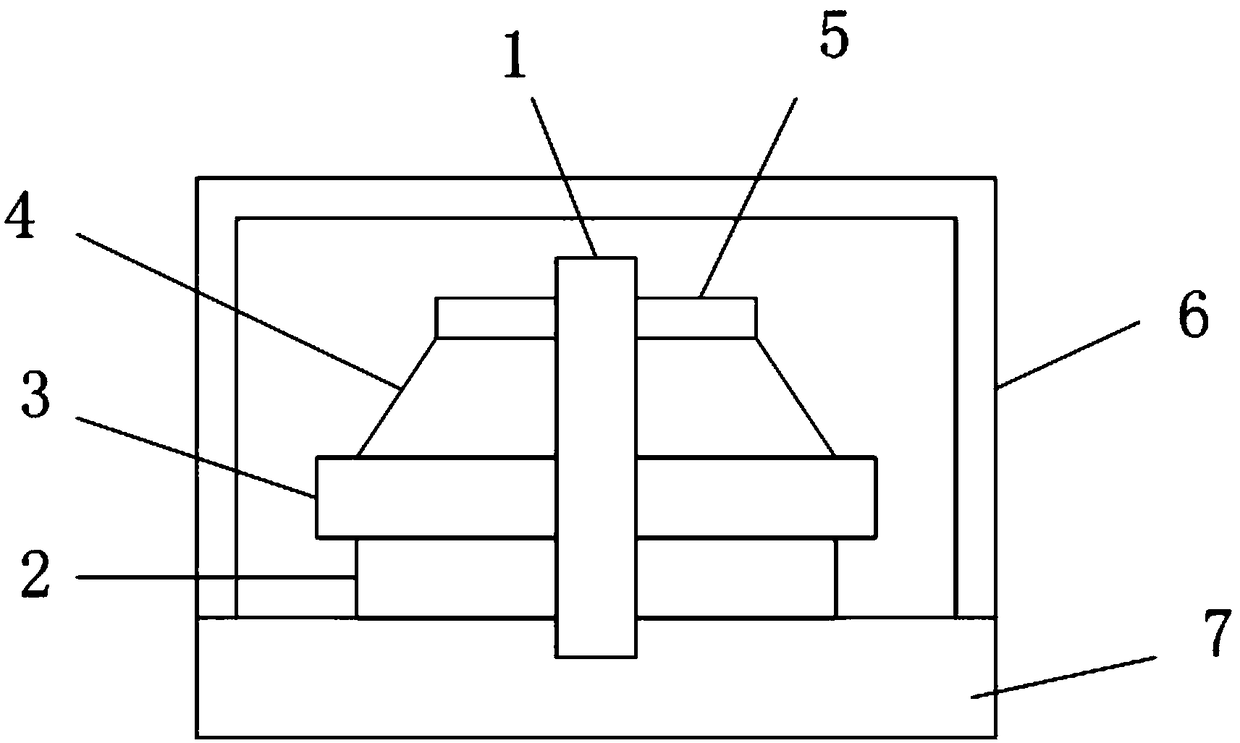

[0070] A high-precision piezoelectric sensor, such as Figure 6 and Figure 7 As shown, including a base 1, a first adhesive layer 2, a piezoelectric film layer 3, a second adhesive layer 4 and a mass 5 arranged on the base 1 in sequence;

[0071] The mass block 5 includes a body 51, a plurality of protrusions 52 located at the bottom of the body 51, and a plurality of vacant parts 53 located at the edge of the protrusions 52, wherein the protrusions 52 and the cavities 53 criss-cross, the The body 51 is cylindrical, with a diameter of 4 mm and a height of 2.8 mm. Both the raised portion 52 and the vacant portion 53 have a width of 0.5 mm and a height of 0.2 mm. The mass 5 is made of copper, tungsten or tungsten copper Made, its weight is 0.4g;

[0072] The piezoelectric film layer 3 includes a support body, a first electrode, a piezoelectric film and a second electrode arranged on the support body in sequence, wherein the first electrode is made of Pt with a thickness of 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com