Automatic intestinal lavage machine for slaughtering animal

A bowel washing machine, automatic technology, applied in the direction of cleaning the bowels, etc., can solve the problems of irregular shape, time-consuming and laborious, low efficiency, etc., and achieve the effect of reasonable structure, convenient use and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

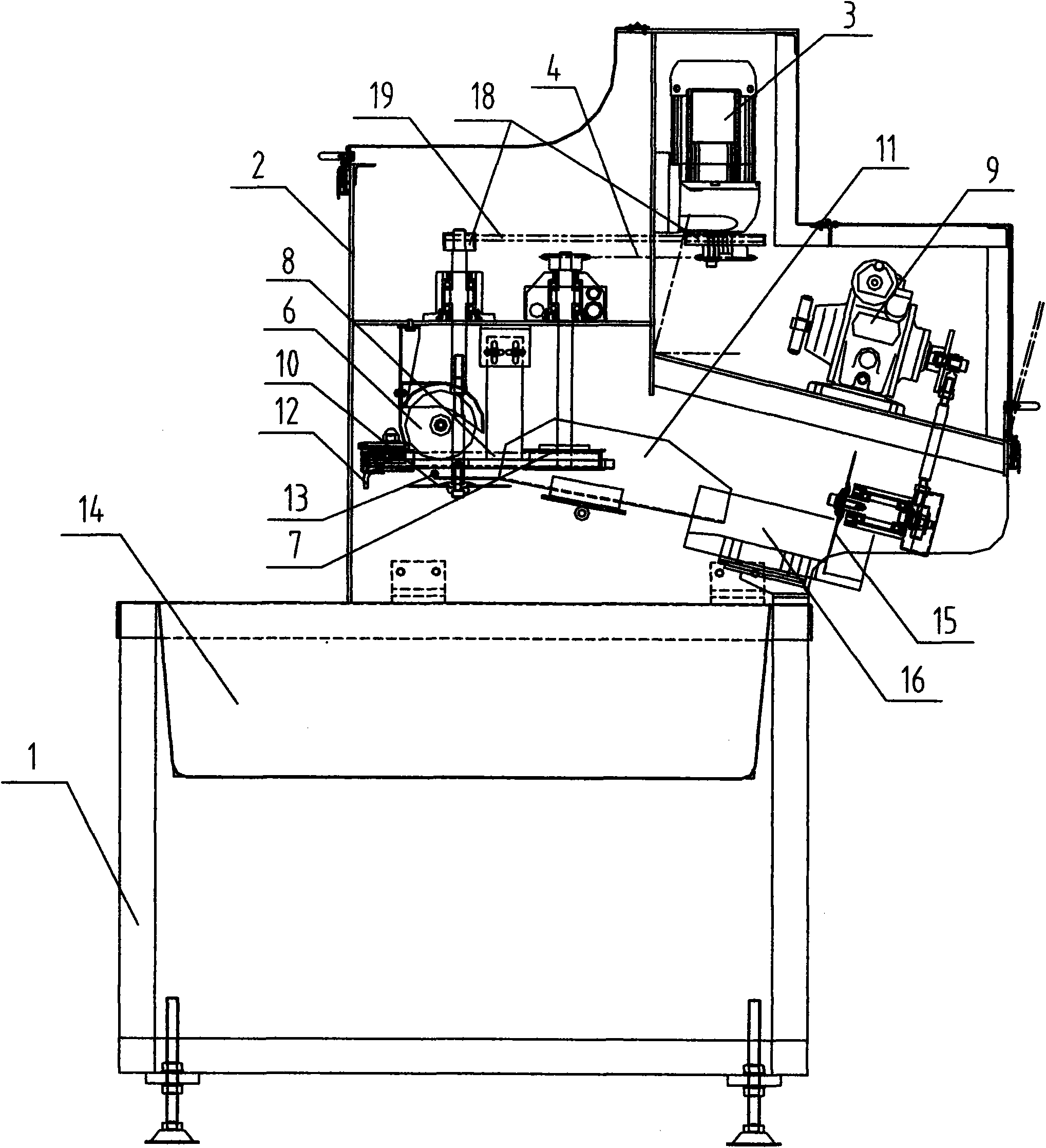

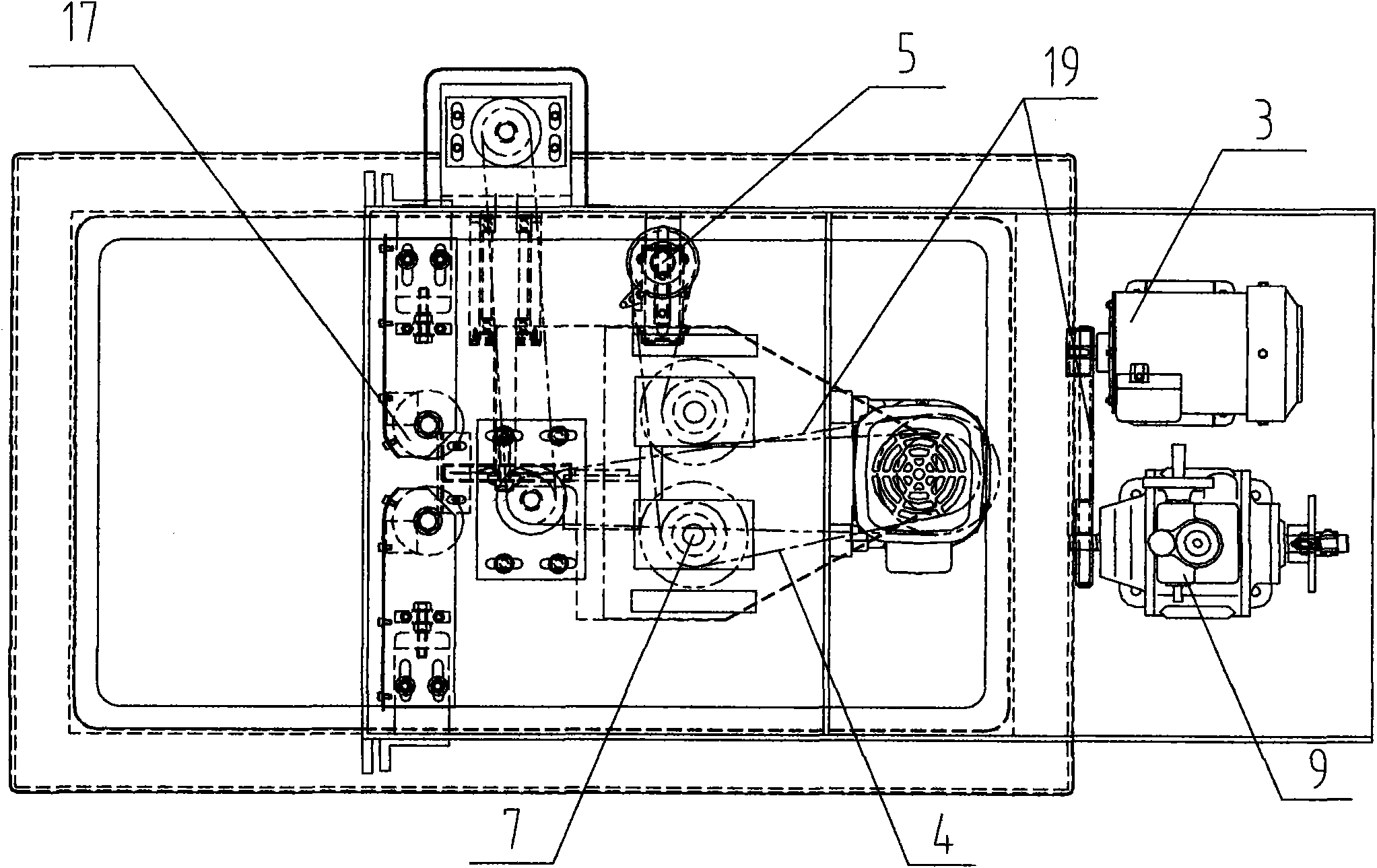

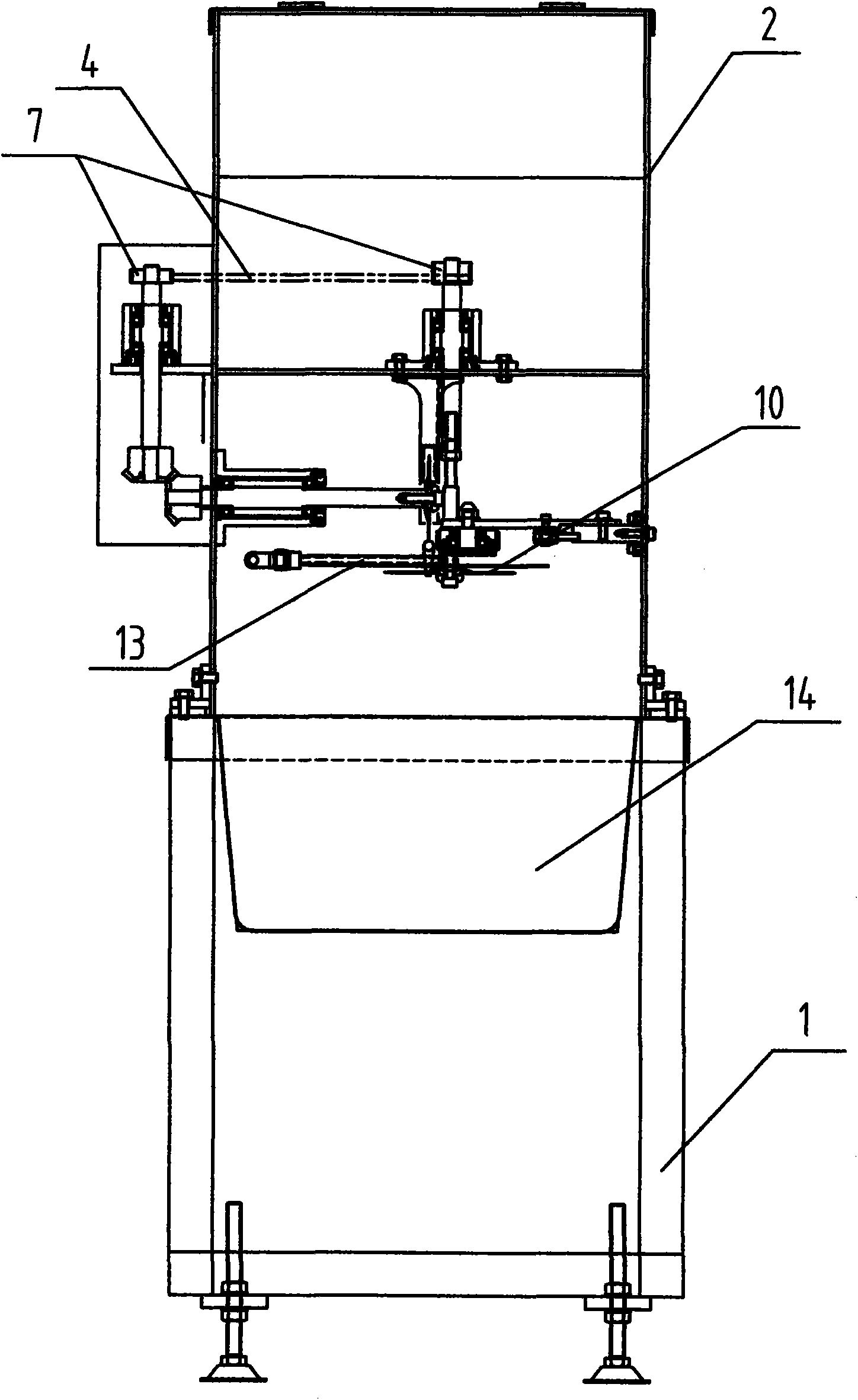

[0015] Specific embodiments of the present invention: such as Figure 1 to 3 As shown, an automatic intestine washing machine for livestock slaughter includes a frame 1, a box 2 is arranged on the upper part of the frame 1, and a motor 3, a conveying and clamping device, a cleaning device and a cutting device are arranged in the box 2 Device, the motor 3 is connected to the conveying and clamping device through the chain 4 and a tensioning mechanism 5. The input end of the conveying and clamping device is connected to a tail-sending device 17, which is a tail-sending pulley, and the cleaning device is set in the conveyor Between the clamping device and the cutting device. A cutting blade 6 is arranged above the conveying device. The conveying clamping device includes two conveying belt wheels 7 and two conveying belts 8. The motor 3 is connected to the conveying belt wheels 7 through a reducer 9; the two conveying belts 8 are respectively It is sleeved on the conveyor belt whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com