A woven artificial blood vessel and the manufacturing method thereof

A technology of artificial blood vessel and manufacturing method, which is applied in the directions of blood vessels, devices of human tubular structures, etc., to achieve the effects of improving the patency rate, improving the uniformity of the structure, and improving the hydrodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

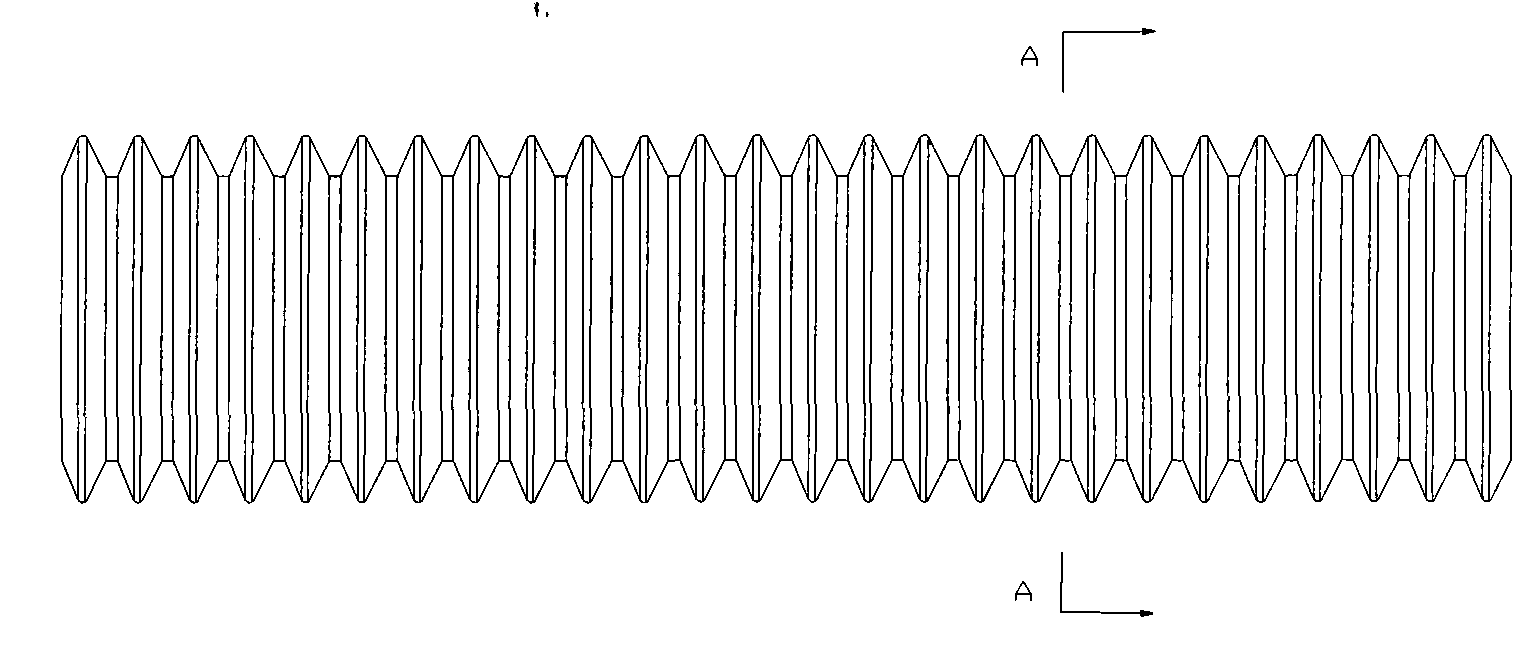

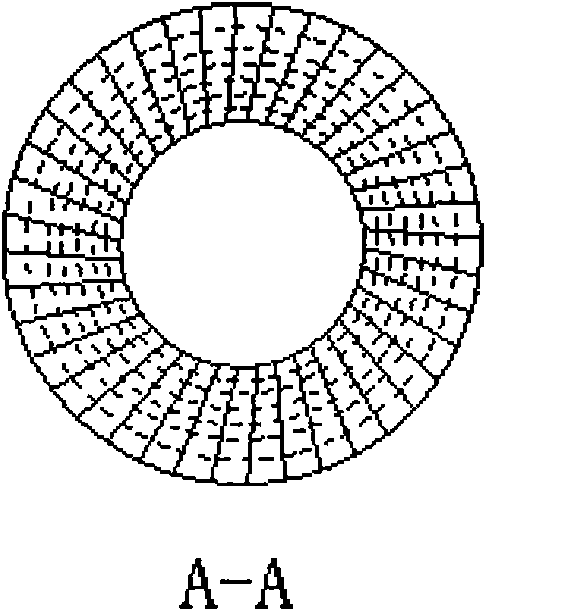

[0032] This embodiment is suitable for woven artificial blood vessels with an inner diameter greater than 10 mm, and the warp and weft yarns used are polyester multifilaments. The basic weave used in the fabric is 2 / 1 twill weave and 6 / 30 variation through heavy flat weave. The two are compounded into oblique convex strip organization a (such as Figure 5 shown). Flip the histogram of oblique strip a according to the film flipping method to obtain the histogram of tissue b (such as Image 6 shown). Finally, the oblique-convex tissue a is used as the surface tissue of the tubular tissue, and the oblique-convex tissue b is used as the inner tissue of the tubular tissue, so that the spiral corrugated tubular tissue diagram is obtained. The artificial blood vessel with helically distributed floating long lines on the inner surface is manufactured by the machine.

[0033] Determine the size and model of the heat-setting thread mold according to the pitch between each formed obl...

Embodiment 2

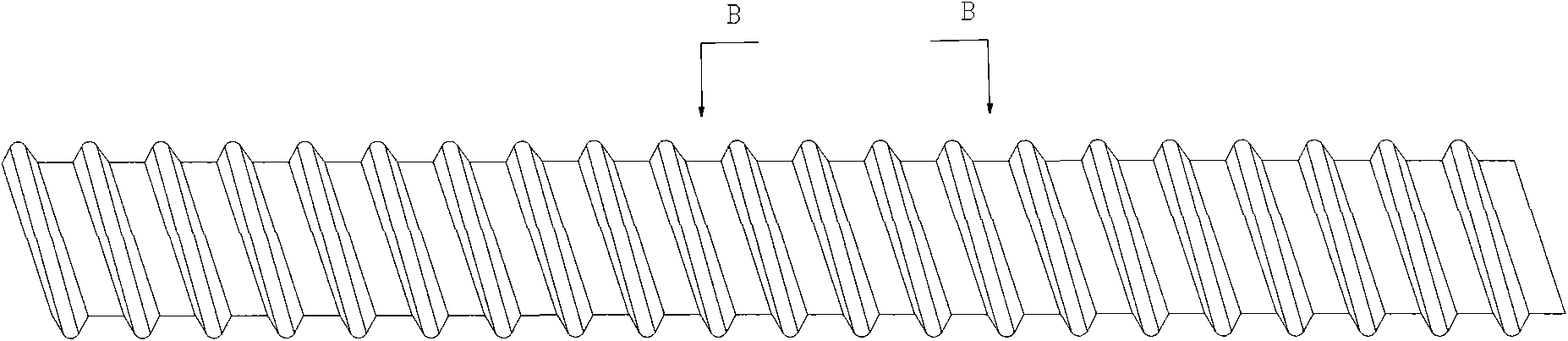

[0036] Choose plain weave and 6 / 30 angle twill weave as the basic weave. The compound composition of the two changes split tissue c (such as Figure 7 Shown), as the surface organization of tubular fabric; change split organization c to get the organization diagram of organization d by negative film flipping method (such as Figure 8 shown), as the inner tissue of the tubular fabric. The artificial blood vessel with helically distributed floating long lines on the inner and outer surfaces is obtained by machine weaving.

[0037] The shaping of the artificial blood vessel requires two molds, one for shaping the floating long lines on the inner surface of the artificial blood vessel, and the other for shaping the floating long lines on the outer surface of the artificial blood vessel. The former is processed into an external thread mold, and the latter is processed into an internal thread mold. Determine the size and model of the heat-setting thread mold according to the pitch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com