Electrostatic spinning production method of conical corrugated small-caliber artificial blood vessel

A technology of artificial blood vessel and production method, which is applied in the direction of human tubular structure devices, blood vessels, non-woven fabrics, etc., can solve the problems of easy occlusion at the bend of the blood vessel, and the preparation method of spiral corrugations is not mentioned, and achieves the reduction of Thrombosis probability, improved hydrodynamic performance, easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

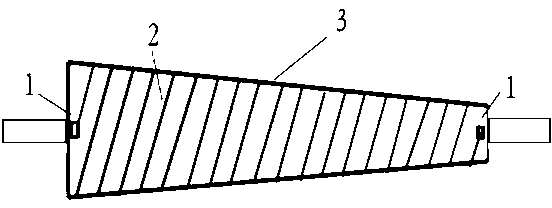

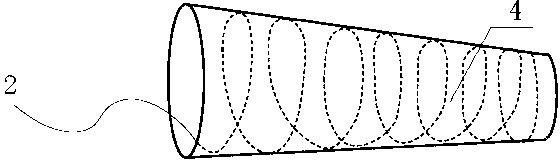

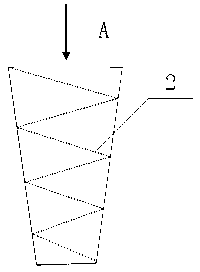

[0023] Such as figure 1 As shown, it is a schematic diagram of the structure of the electrospinning collection device. The electrospinning collection device includes a conical collection roller 3, and the two ends of the conical collection roller 3 are fixed by the fixing device 1. A spiral corrugation processing device 2 is fixed. Described conical collection roller 3 is that the cone angle is 1 °, and the length is the aluminum matter truncated cone collection roller of 20cm. The spiral corrugation processing device 2 is a polyester strand (15D / 130F×3) wound on the outside of the conical collecting roller 3 in a spiral corrugation manner. The maximum angle is 5°, and the thread pitch is 2mm.

[0024] Dissolve polyester chips with an intrinsic viscosity of 0.8 in a mixed solution of trifluoroacetic acid and dichloromethane (volume ratio 4:1) to prepare a spinning solution with a mass fraction of 10%, and suck the spinning solution into the spinning tube , the inner diamete...

Embodiment 2

[0026] Such as figure 1 As shown, it is a schematic diagram of the structure of the electrospinning collection device. The electrospinning collection device includes a conical collection roller 3, and the two ends of the conical collection roller 3 are fixed by the fixing device 1. A spiral corrugation processing device 2 is fixed. Described conical collection roller 3 is that the cone angle is 3 °, and the length is the aluminum matter truncated cone collection roller of 20cm. The spiral corrugation processing device 2 is a polyester strand (15D / 130F×3) wound on the outside of the conical collecting roller 3 in a spiral corrugation manner. The maximum angle is 45°, and the thread pitch is 2mm.

[0027] Dissolve polylactic acid (PLLA) with a molecular weight of 100,000 in a mixed solution of chloroform and acetone (volume ratio 2:1) to prepare a spinning solution with a mass fraction of 5%, and suck the spinning solution into the spinning tube , the inner diameter of the ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com