A thermogravimetric analysis system capable of high-precision initial stability measurement

A thermogravimetric analysis, high-precision technology, applied in the direction of measuring devices, material analysis, material analysis by electromagnetic means, etc., can solve the problems of air flow disturbance effect that is difficult to ignore, noise signal reduction, corrosion of electronic balances, etc. Effects of baseline drift, impact reduction, and corrosion suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

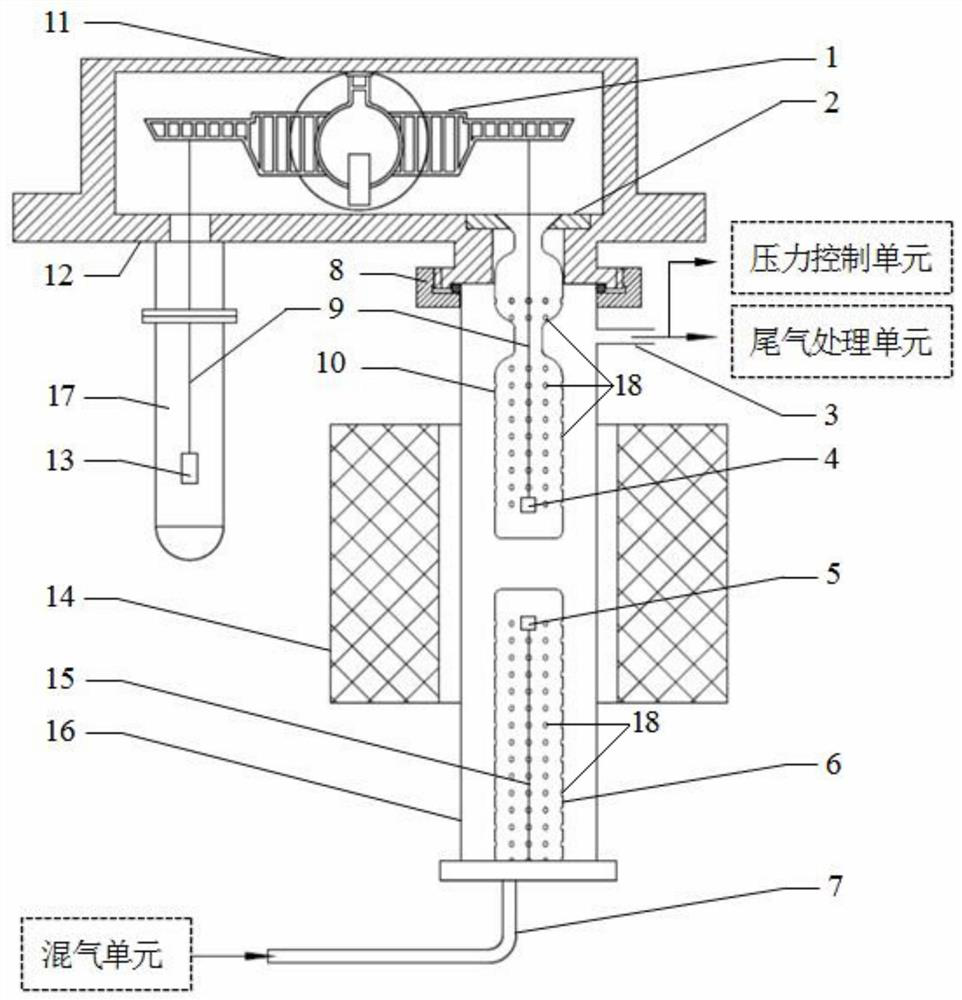

[0032] like figure 1 As shown, in this embodiment, the basic structure of a thermogravimetric analysis system that can realize high-precision initial stable measurement, the system includes a reactor, an electronic balance weighing device, an infrared radiation heating device 14, and a gas control device. The specific structure is as follows:

[0033]The electronic balance weighing device is located above the reactor, and the reactor is passed through the central hole of the annular infrared radiation heating device 14; the electronic balance weighing device includes an electronic balance 1, a sealing cover 11, an electronic balance weighing device base 12, and an electronic balance scale. The top of the base 12 of the measuring device is provided with a sealing cover 11 to form an electronic balance room. The electronic balance 1 is located in the electronic balance room. A balance weight 13 is installed at the lower end of 9, the balance weight 13 is located in the sealing t...

Embodiment 2

[0040] This embodiment further illustrates the beneficial effect of the present invention in reducing the noise signal of thermogravimetric data in combination with the simulation calculation.

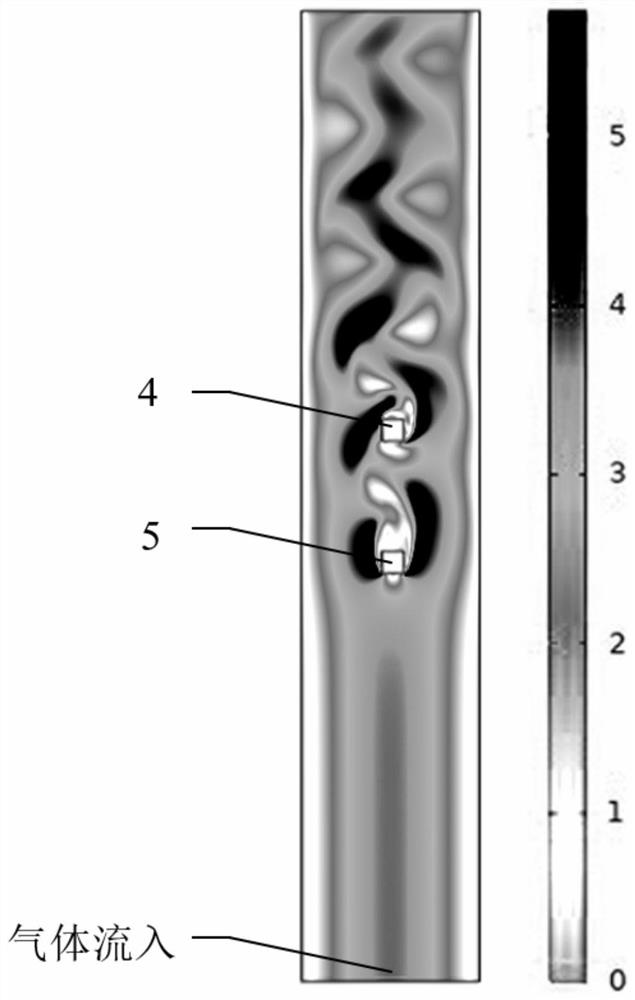

[0041] like figure 2 As shown in the schematic diagram of the simulation of the gas flowing through the sample under the structural condition of the conventional reactor (single-walled quartz tube), it can be seen that without the porous quartz inner tube structure, the gas flowing through the weighing sample will produce a large airflow disturbance. effect, thereby reducing the signal-to-noise ratio of the thermogravimetric data.

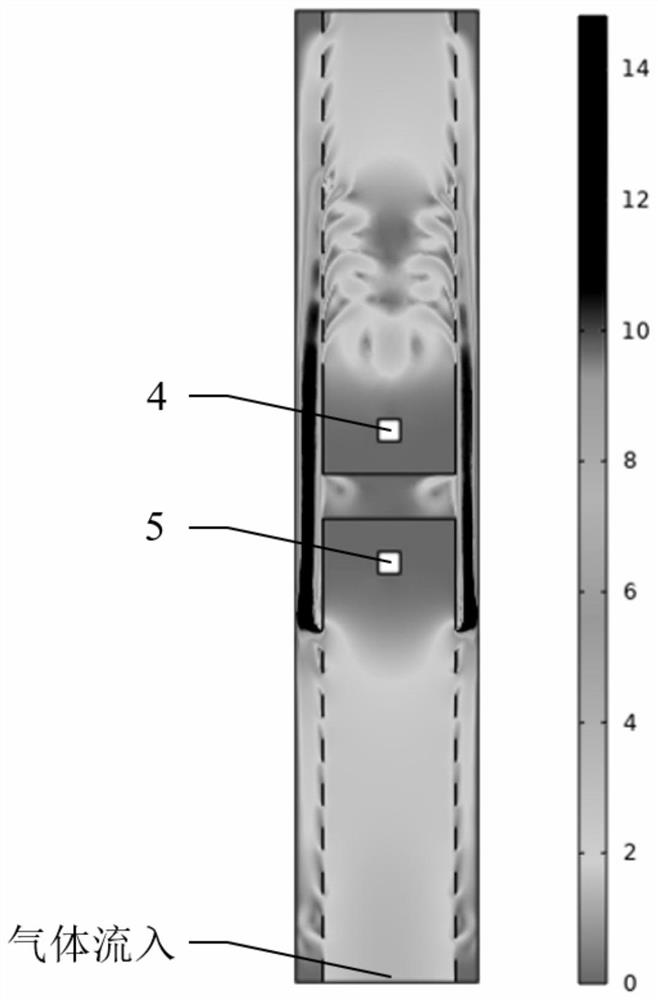

[0042] like image 3 and Figure 4 As shown, in the case of different quartz inner tube opening structures, the simulation is the same as figure 2 The gas parameter settings are exactly the same. It can be seen from the simulation schematic diagram of the gas flowing through the sample under the structural conditions of the reactor according to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com