Condensing well for breathing tube

A technology of condensation traps and hoses, which is applied in the field of condensation traps of breathing hoses, and can solve the problems that condensation traps cannot be installed and condensed water cannot be discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

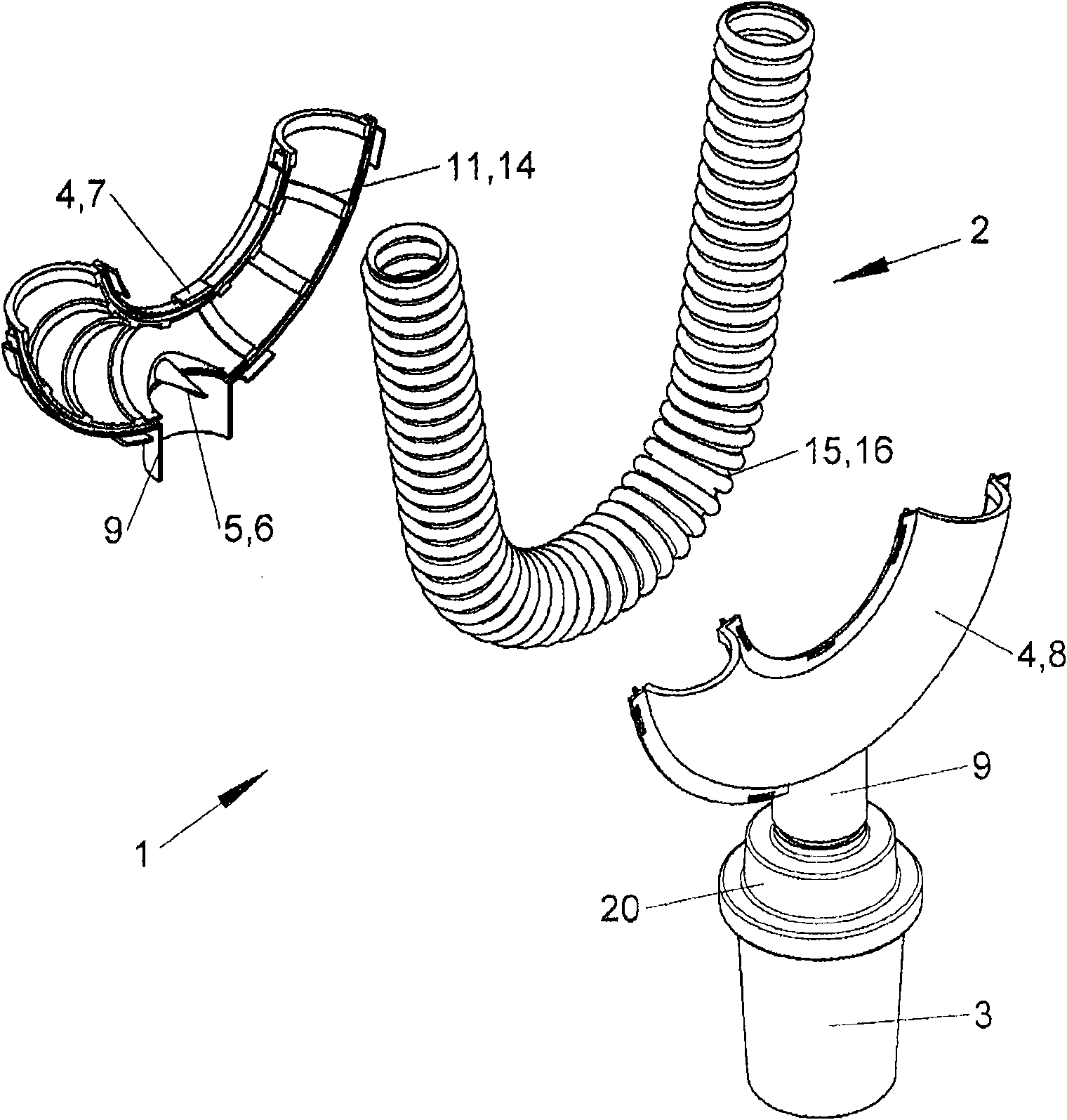

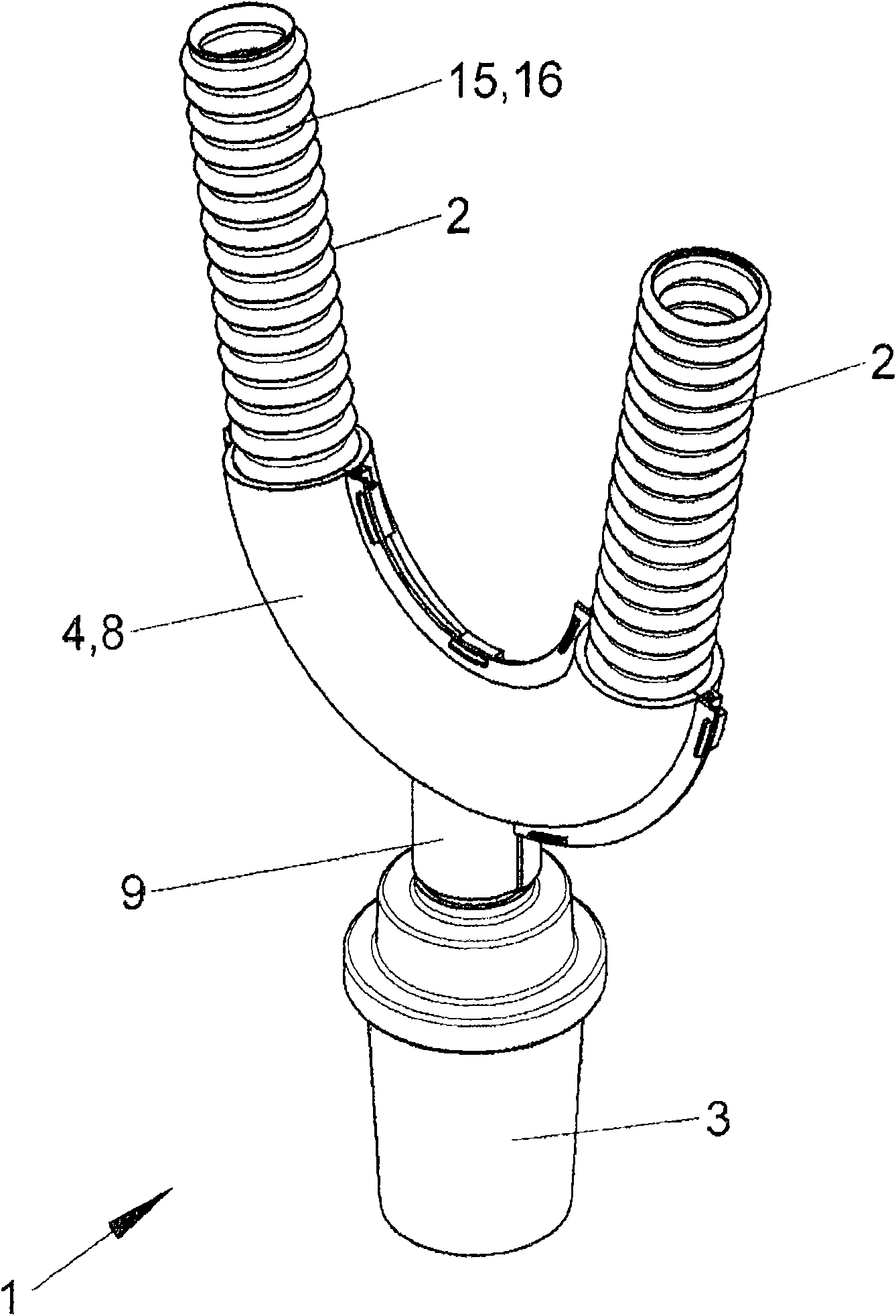

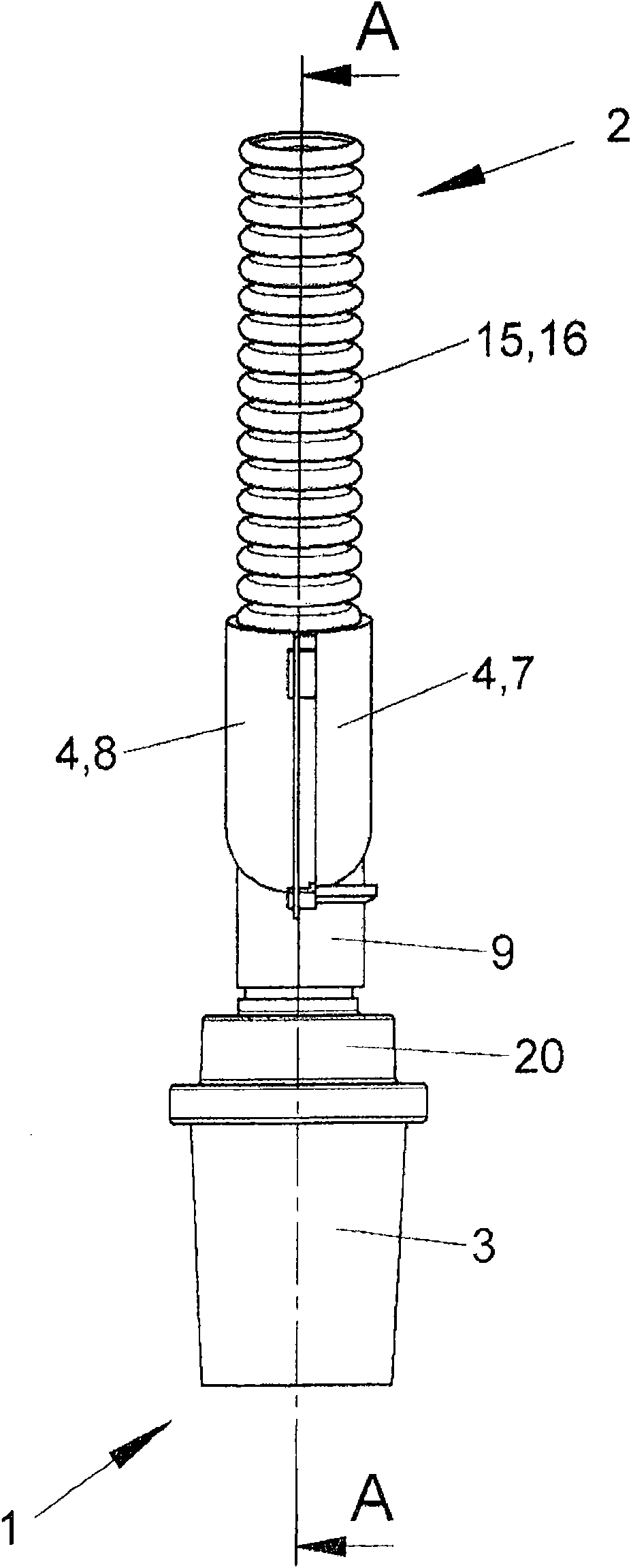

[0035] Figures 1 to 5 The condensation trap 1 shown is used to drain condensation from the breathing hose 2 of the breathing system. The condensation trap 1 thus prevents a large amount of condensed water from accumulating in the breathing tube, thereby preventing an increase in the air resistance in the breathing tube 2 or the penetration of condensed water into the lungs of the breathing patient.

[0036] The condensation trap 1 comprises a collector 3 for collecting condensed water and means 4 for fastening the collector 3 to the breathing hose 2 . The tool 4 consists of a first half shell 7 and a second half shell 8 ( figure 1 , 2 , 3 and 5). On the first half shell 7 there is a tool 5 for processing a hole in the breathing hose 2, which tool is made into a punch 6 ( figure 1 , 6 and 7), the breathing hose 2 made of plastic and flexible has a tangential groove 15 formed as an annular groove 16 ( Figures 1 to 5 ). The first and second half-shells 7, 8 have a U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com