Omnidirectional wheel with simplified manufacturing technique

An omnidirectional wheel and roller technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., to achieve the effect of smooth movement, compact structure and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

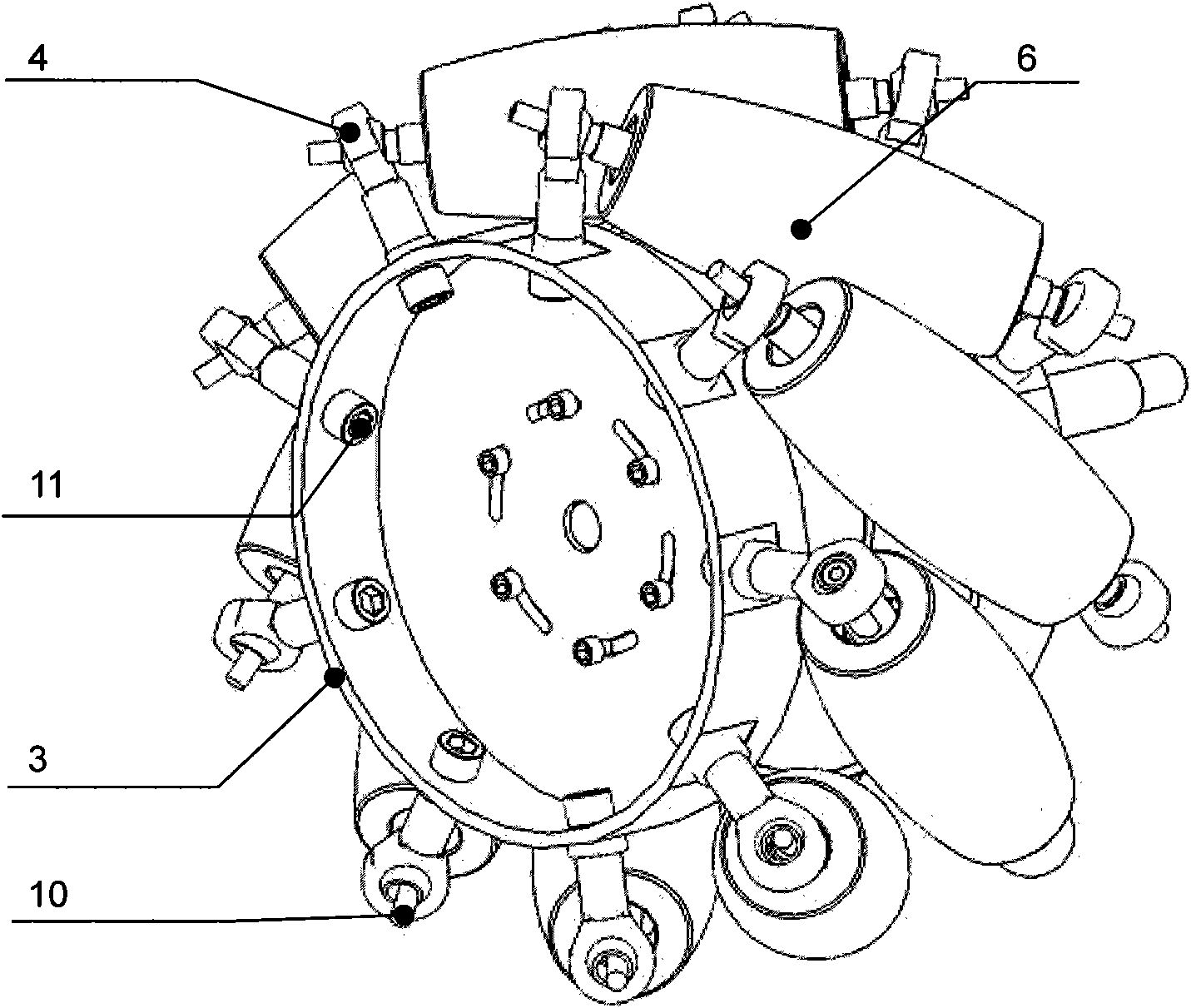

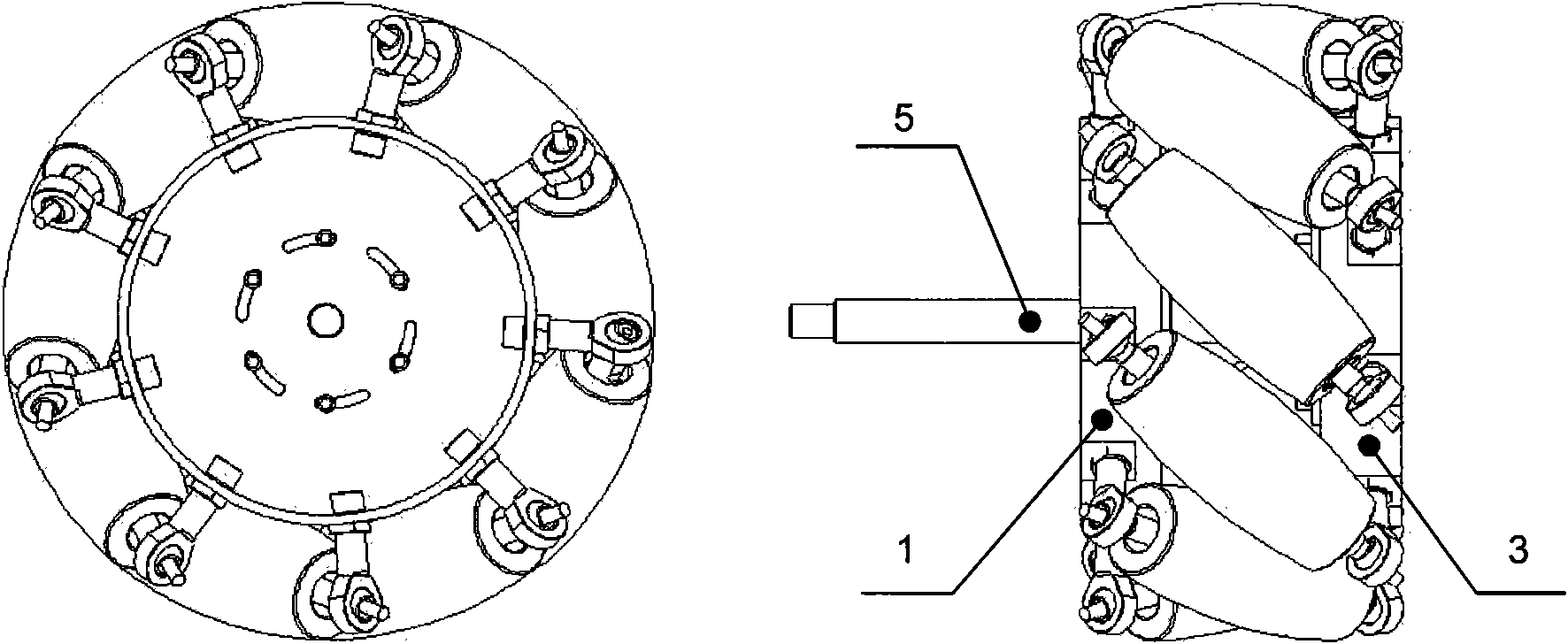

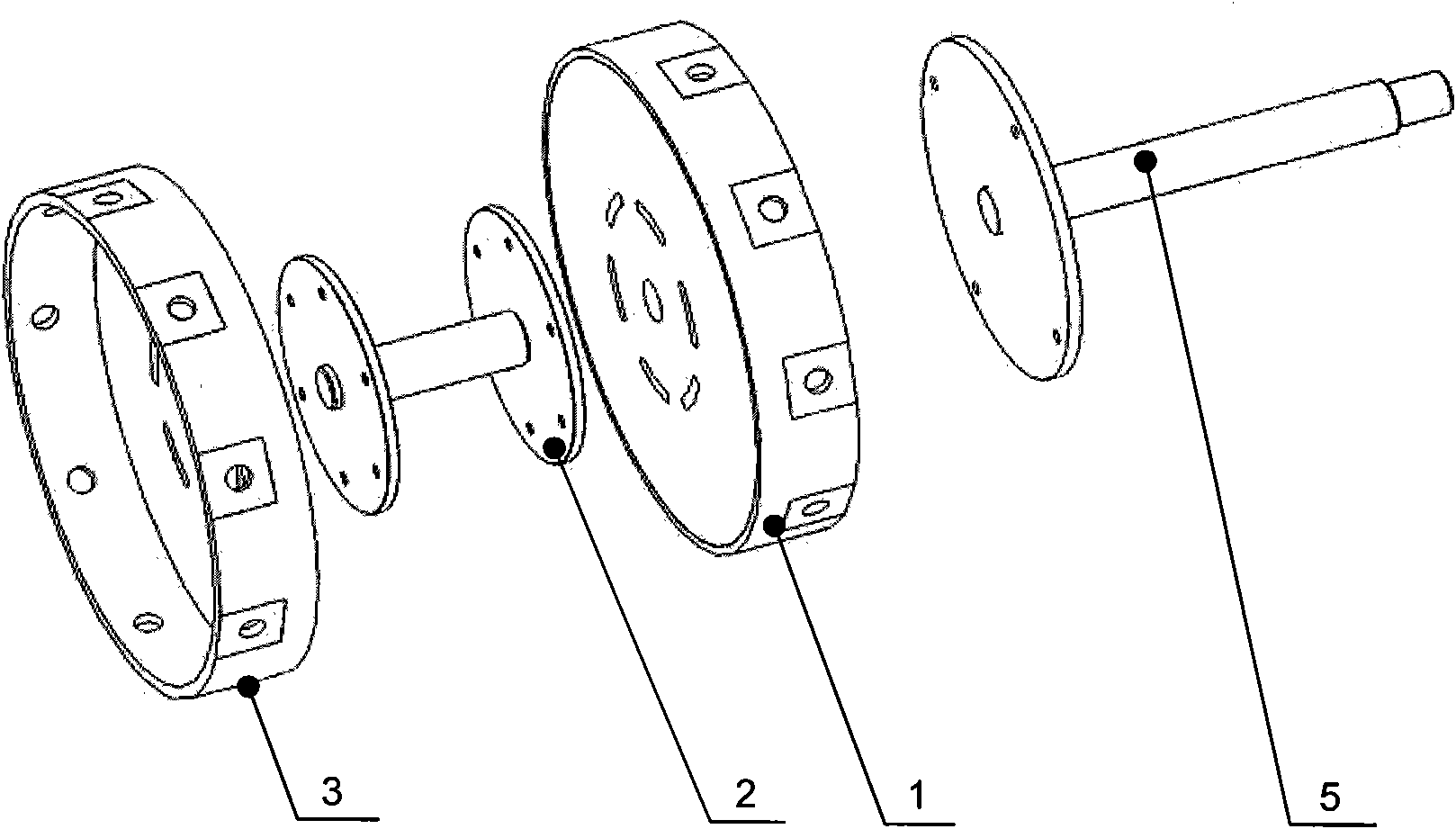

[0016] The omnidirectional wheel implemented in the present invention is mainly composed of the following components: inner hub 1, connecting flange 2, outer hub 3, joint bearing 4, drive shaft flange 5, roller 6, internal thread half shaft 7, external thread Half shaft 8, roller bearing 9, half shaft bolt 10, joint bearing fixing bolt 11.

[0017] The inner hub 1 is connected with the outer hub 3 and the drive shaft flange 5 through the connecting flange 2 to form a coaxial structure; the joint bearing 4 is connected to the inner hub 1 and the outer hub 3 by joint bearing fixing bolts 11 The roller 6 and the roller bearing 9 are connected together by the threads of the internally threaded half shaft 7 and the externally threaded half shaft 8 to form a roller train; The joint bearing 4 on the wheel hub 3 is connected.

[0018] The following components are all taken from the standard parts: joint bearing 4, roller bearing 9, half shaft bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com