80km/h speed class b-type subway vehicle bogie

A technology of speed grade and bogie, which is applied in the direction of bogie, device for lateral relative movement between the chassis and bogie, railway car body parts, etc. Problems such as poor dynamic performance, achieve superior dynamic performance, reduce noise pollution, and reduce mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

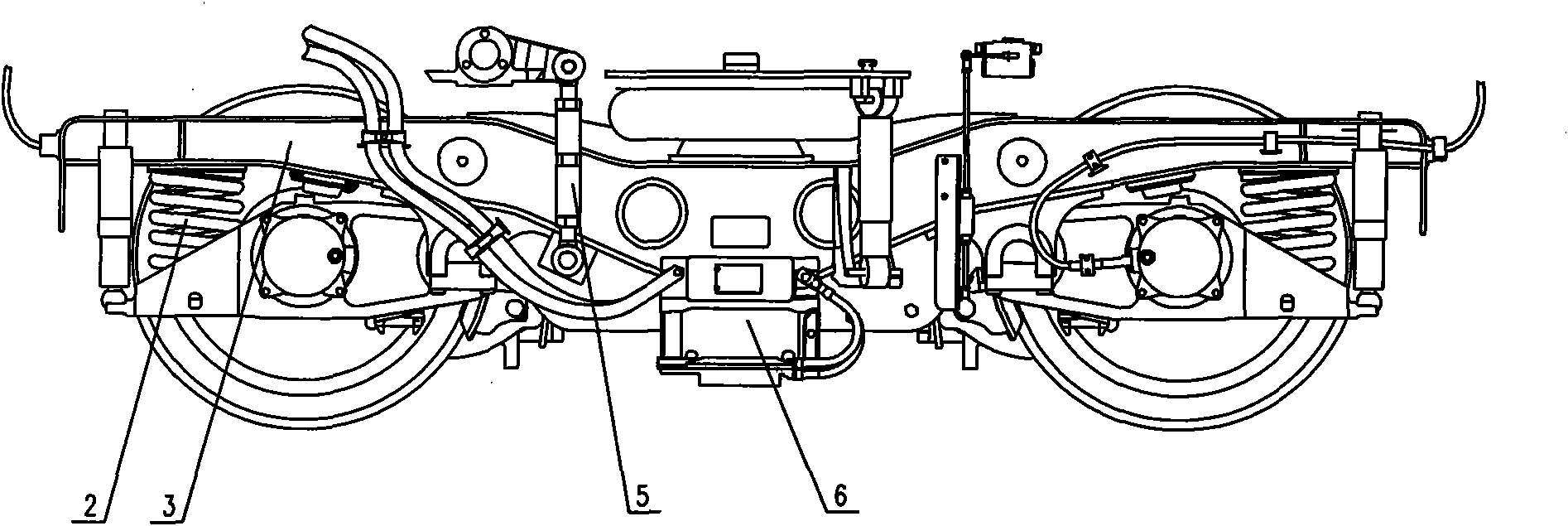

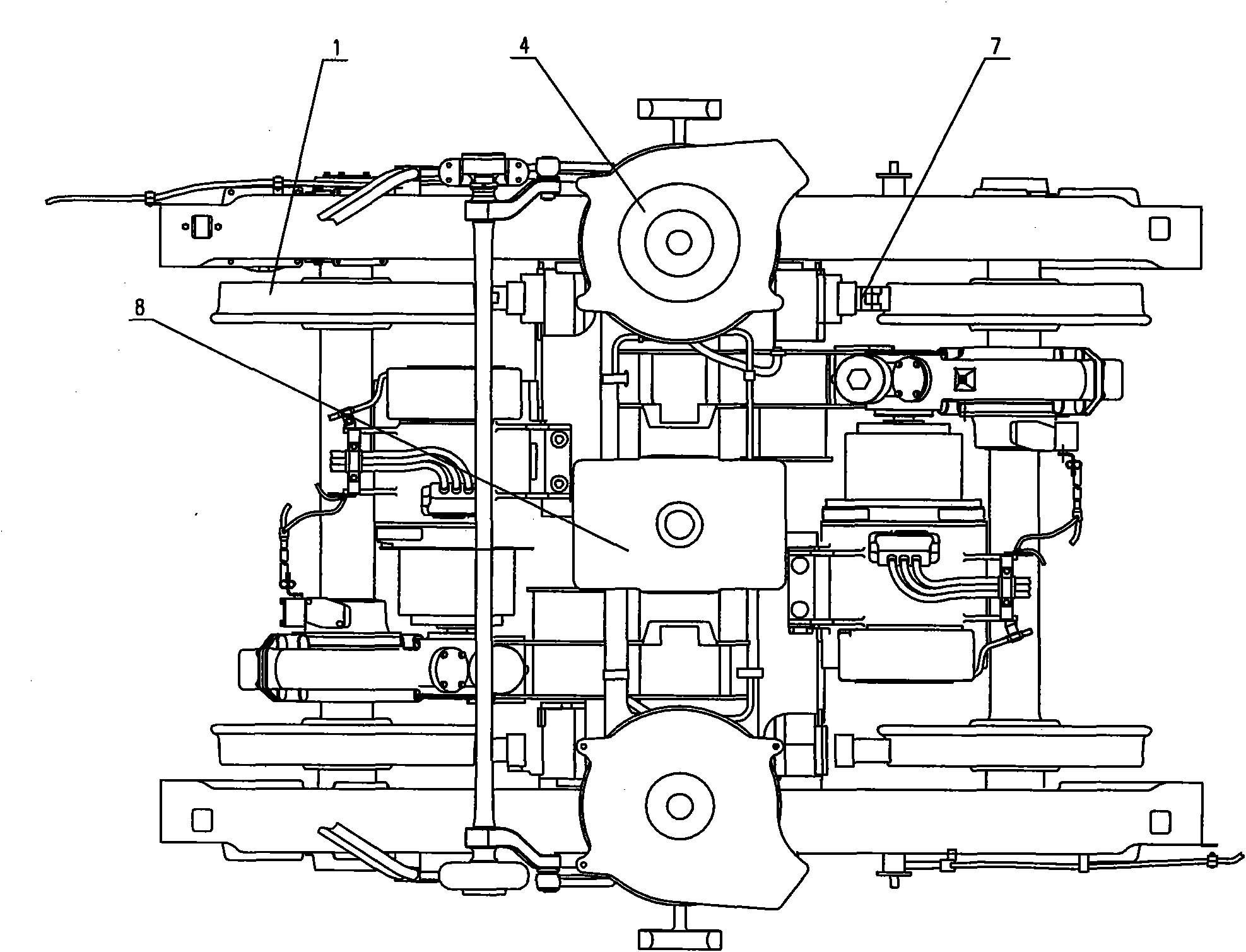

[0048] A kind of 80km / h speed class B type subway car bogie, refer to Figure 1~3 As shown, the frame 3, the driving device 1 mounted on the frame 3 for transmitting driving force, the primary suspension 2, the secondary suspension 4 mounted on the frame 3 for supporting the vehicle body, and the connecting frame 3 and the vehicle body are used together. Traction device 8 for transmitting traction and braking force, anti-rolling device 5 for connecting frame 3 and vehicle body and restraining the rolling tendency of vehicle body, foundation braking device 7 installed on the side beam of frame 3 for transmitting braking force It is composed of the third rail current collector 6 which is installed on the side beam of the frame 3 and acts as a current collector.

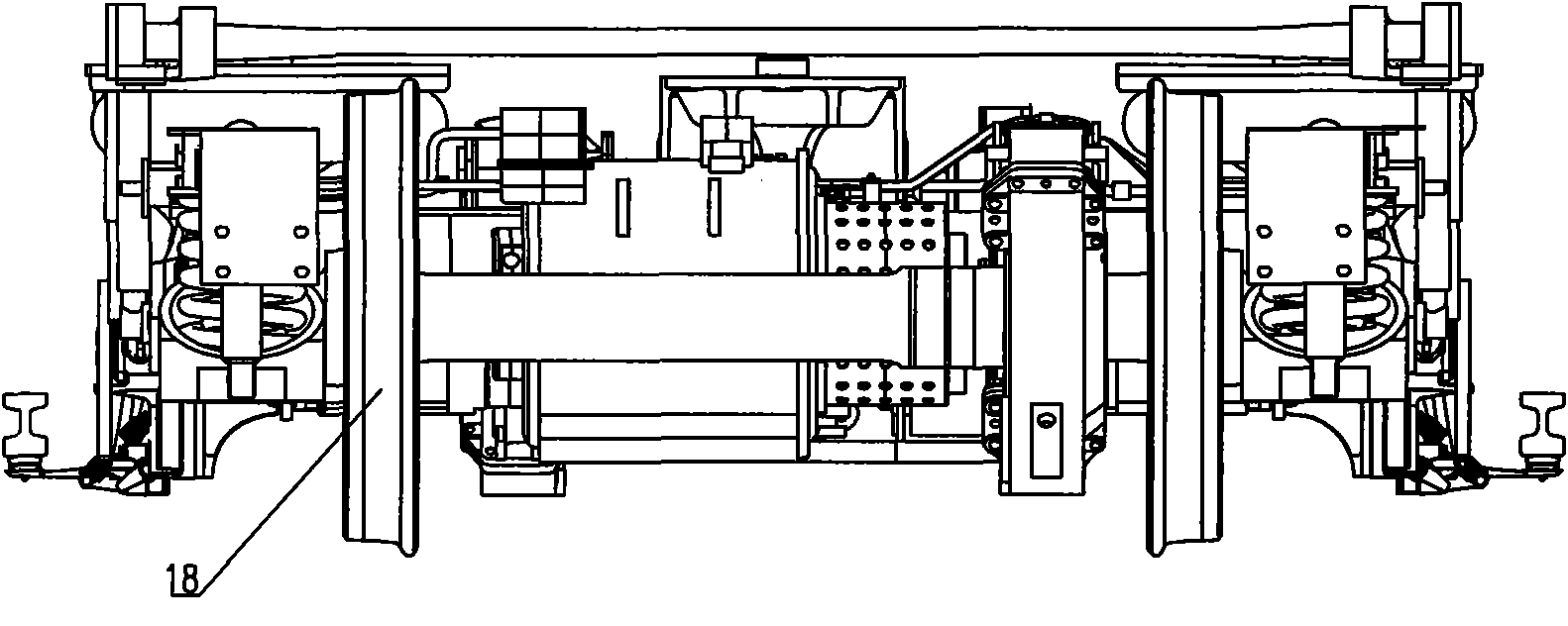

[0049] refer to Figure 4~5 As shown, the frame 3 is an "H"-shaped welded frame composed of a left side beam 9, a right side beam 10 and a cross beam 11, and various mounting seats are also welded on the frame 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com