FSC (Formula Student China) formula car carbon fiber suspension and adhesion technology thereof

A formula racing and carbon fiber technology, applied in the field of Formula Student racing suspension, can solve problems such as the large influence on the fuel economy and dynamic performance of the racing car, the poor maintainability of the steel pipe suspension, and the easy occurrence of rust and fatigue, so as to reduce the operating cost. and carbon dioxide emissions, short glue curing time, the effect of reducing repair time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

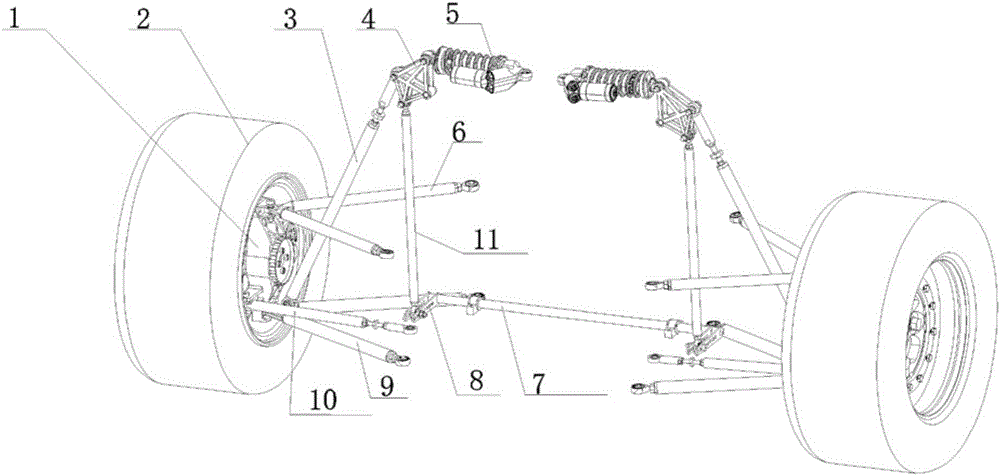

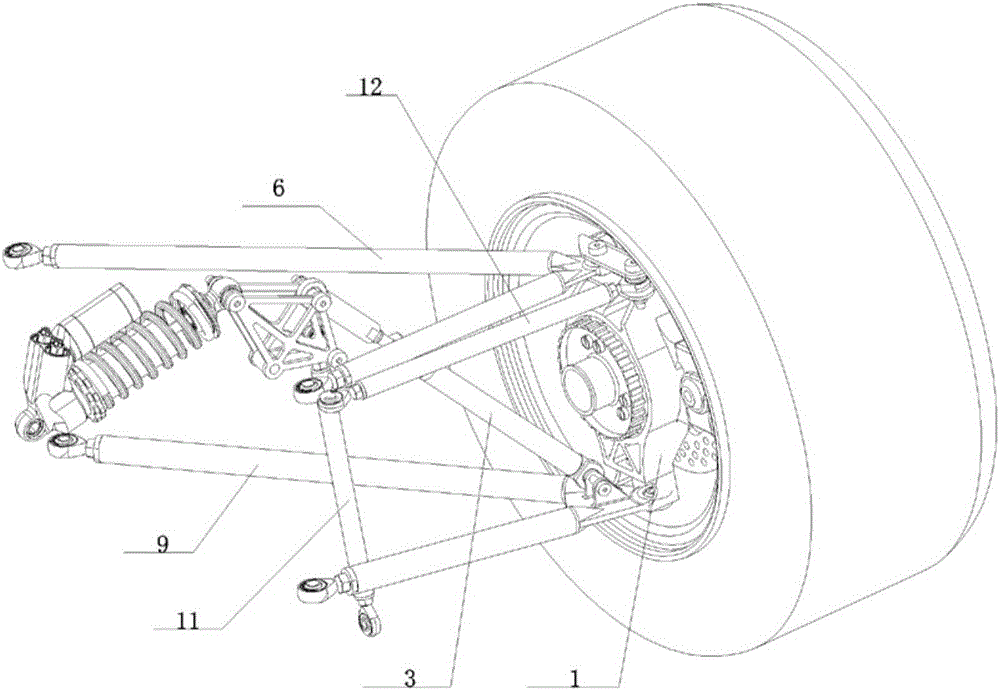

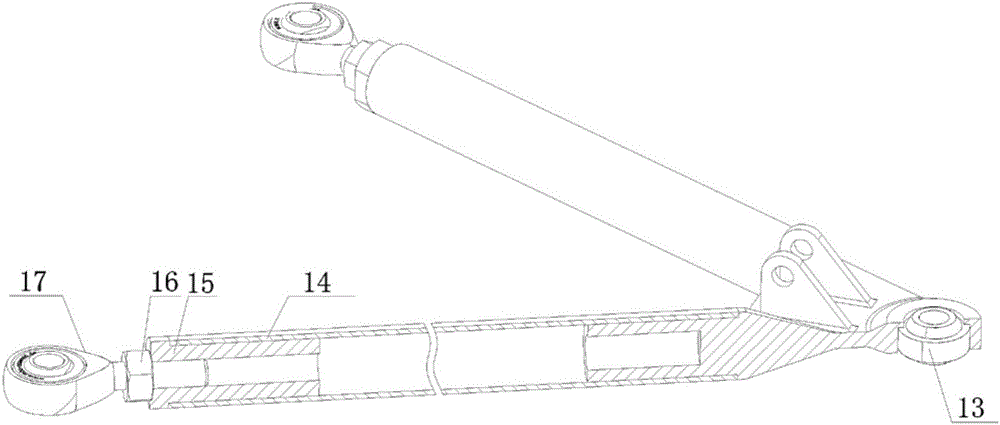

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, a carbon fiber suspension for a FSC formula racing car includes a column 1 for connecting tires 2, and the inner side of the column 1 is connected with the vehicle frame through a guide mechanism. The guide mechanism includes an upper cross arm 6, a lower cross arm 9, a push rod 3 and rocking arm 4; the far-end of upper cross arm 6 and lower cross-arm 9 is hinged on the column 1, and the near-end is used for being connected with vehicle frame; The far-end of push rod 3 is hinged with the far-end of lower cross-arm 9, pushes The proximal end of the rod 3 extends obliquely upwards and is connected to the rocker arm 4; it also includes a stabilizer bar 7, each of which ends of the stabilizer bar 7 is fixedly connected to a swing arm 8, and the two swing arms 8 are respectively connected to the left and right sides through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com