Method and device for preventing and removing scales, removing oxygen, cleaning, sterilizing and removing algal by using ultrasonic waves

An ultrasonic and equipment technology, which is applied in the fields of ultrasonic anti-scaling, descaling, oxygen removal, cleaning, sterilization and algae removal, and equipment, can solve problems such as oxygen corrosion, scale corrosion, equipment cleaning, steam cleaning, etc., to increase resistance , Conducive to the effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

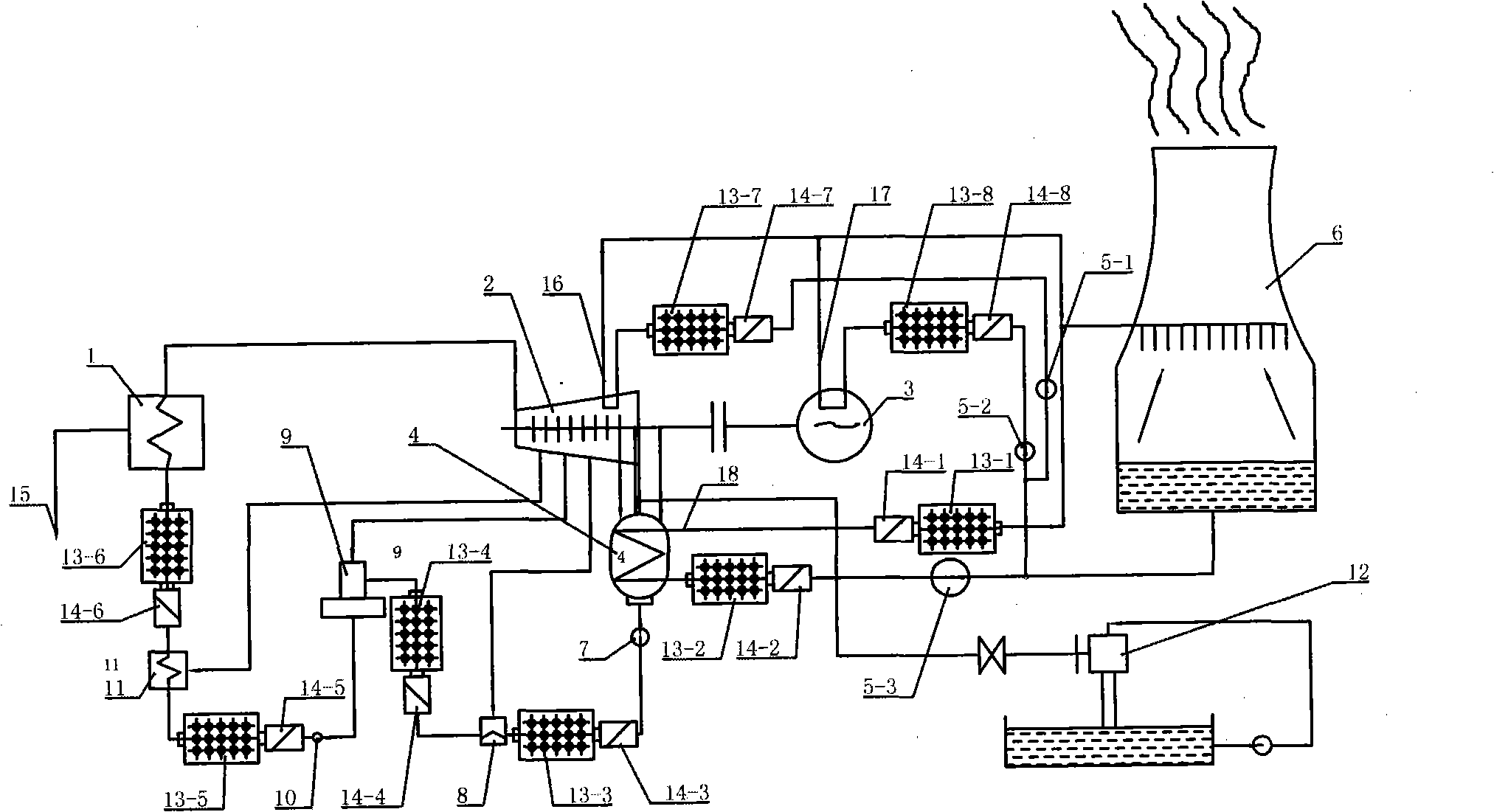

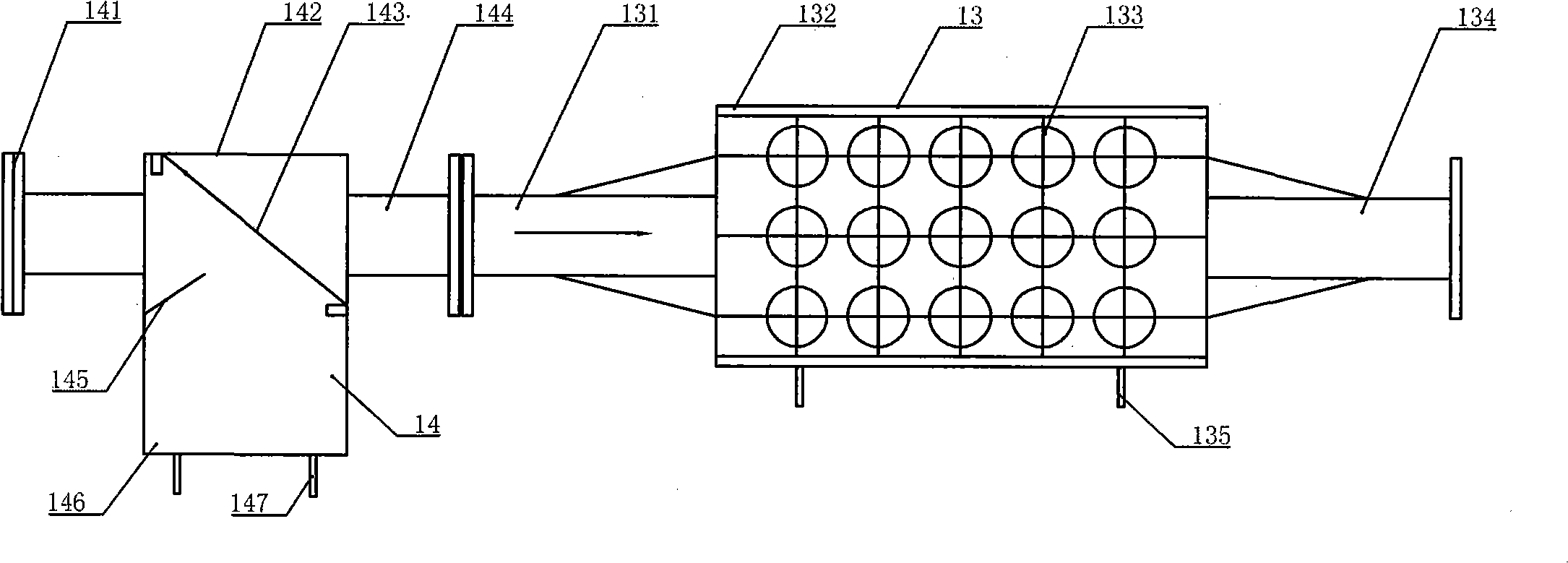

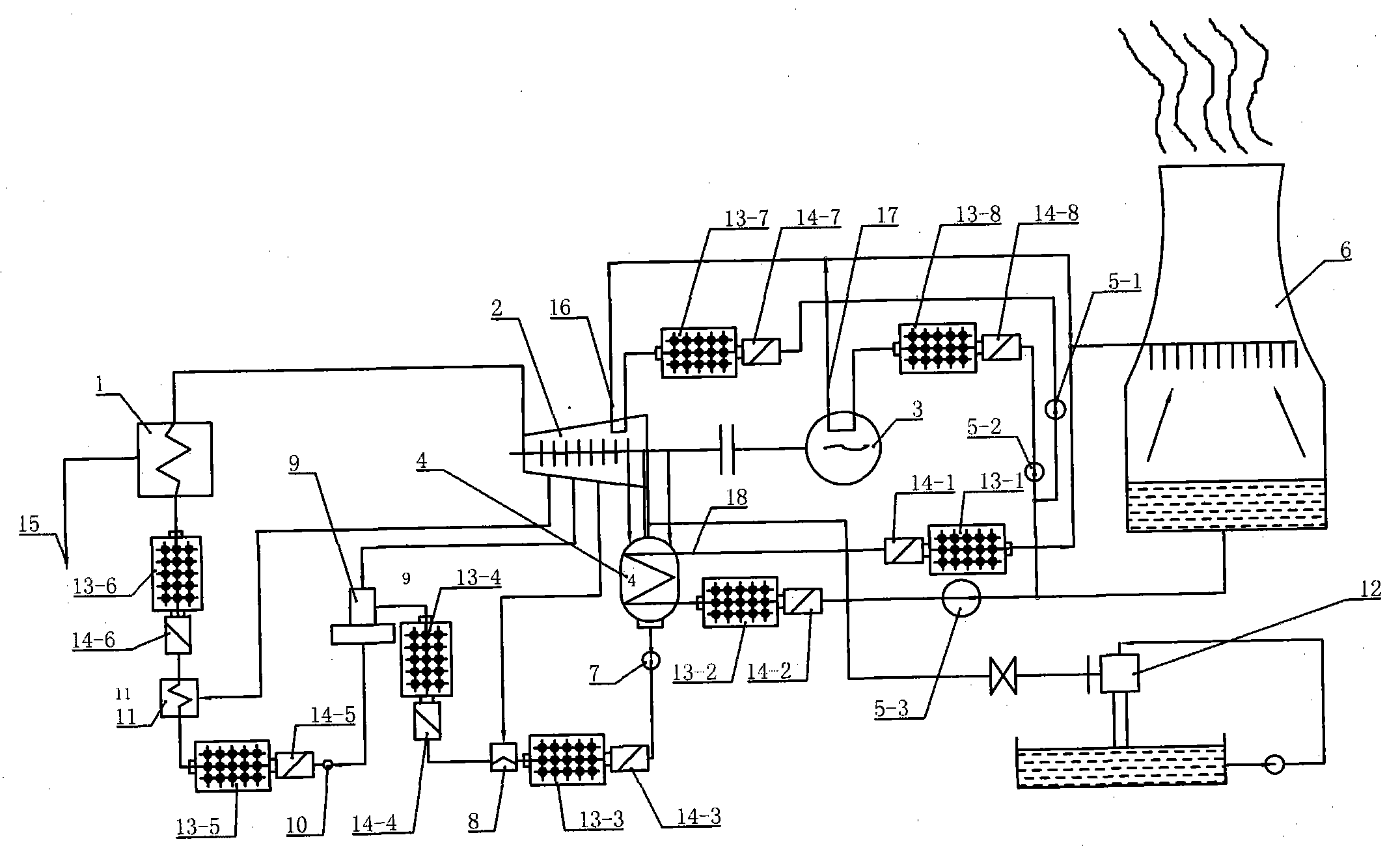

[0019] see figure 1 , a method and equipment for anti-scaling, descaling, deoxygenation, cleaning, sterilization, and algae removal using ultrasonic waves in the present invention are characterized in that: in the working medium circuit and cooling medium circuit of thermal power equipment, firstly, the dirt is passed through The filters 14-1 to 14-8 filter the dirt, and then use the ultrasonic processor 13-1 to 13-8 to prevent scale, remove scale, remove oxygen, clean, sterilize, and remove algae from the filtered water. deal with.

[0020] The working medium circuit includes: boiler 1→steam turbine 2→condenser 4→condensate pump 7→low temperature heater 8→deaerator 9→feed water pump 10→high temperature heater 11→boiler 1.

[0021] The cooling medium circuit includes: the outlet of the cooling tower 6 respectively passes through three parallel circulating water pumps 5-1 to 5-3 and the cooling circuit of the steam turbine 2, the cooling circuit of the generator 3 and the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com