Emergency processing method and device for falling of sliding valve gate plate through catalyst

An emergency treatment and catalyst technology, applied in valve devices, sliding valves, valve details, etc., can solve problems such as large profit loss, safety problems, long maintenance time, etc., and achieve the effect of huge benefits and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

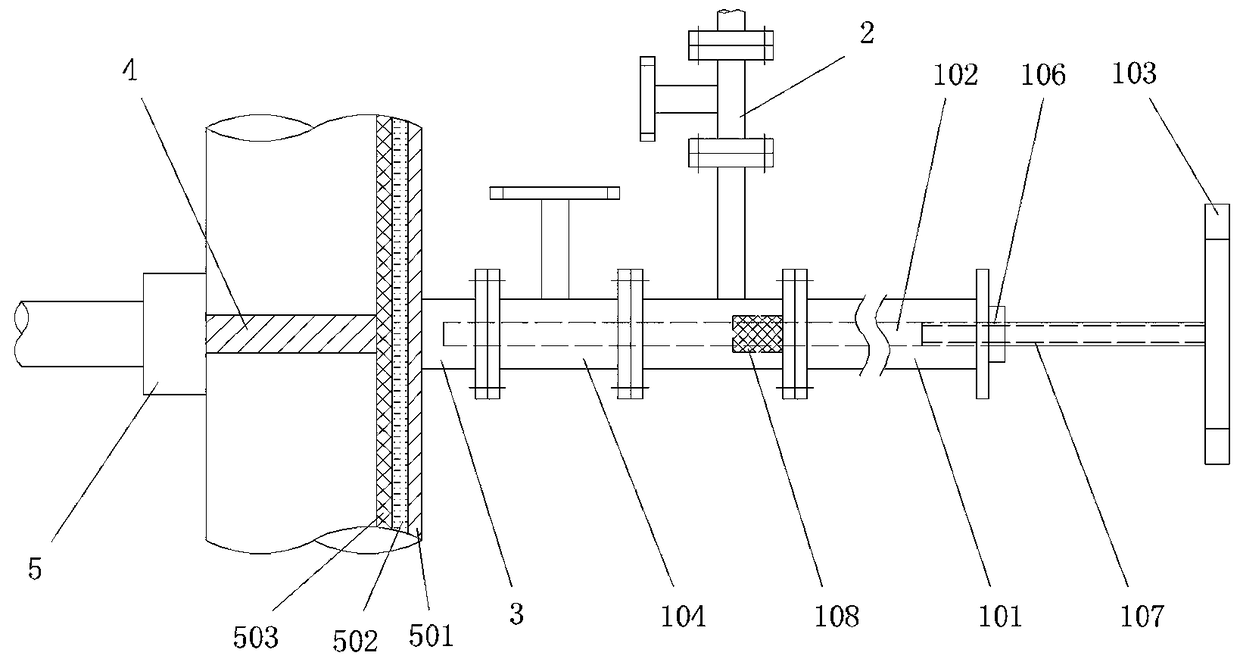

[0019] like figure 1 As shown in the figure, an emergency treatment device for catalyst spool valve gate falling off includes a gate ejection device and a purge bypass 2. The gate ejection device includes a cylinder 101, a lead screw ejector rod 102, and a valve handle 103. One end of the barrel 101 is connected to the flange nipple 3 through a gate valve 104, and the other end is provided with a threaded hole 106. The screw jack 102 passes through the threaded hole 106, and one end penetrates the barrel 101 and extends into the flange nipple. Section 3, the other end is connected to the valve handle 103, and the end connected to the valve handle 103 is provided with a screw thread 107 that matches the threaded hole 106. Rotating the valve handle 103 can make the screw rod 102 move in the cylinder body 101, and the slide valve gate can be moved. When the plate 4 pushes back to 100% opening, it can also withdraw from the internal channel of the slide valve, without hindering th...

Embodiment 2

[0022] A method for disposing of a damaged slide valve using the emergency treatment device for the gate plate falling off of the catalyst slide valve described in Example 1. The valve body 5 of the slide valve includes three layers from the outside to the inside: a shell made of metal material 16Mn and a wall thickness of 20mm Body 501; thermal insulation lining 502 with a thickness of 80mm; silicon cross-network 503 with a thickness of 20mm, and a medium temperature of 650°C, including the following steps:

[0023] S1: Install the flange nipple 3 at the precise position on the back of the spool valve 5 and perform pressure drilling. The effective length of the drilling knife is greater than 140mm, and the length calculation method is 20+80+20+6 (thickness of the bottom of the knife) + 14 ( The invalid length of the tip or drill tip), the material is a high-temperature alloy knife, and the hardness is higher than that of silicon cross-network 503;

[0024] S2: Install the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com