Sludge-sucking robot

A robot and silt technology, applied in the direction of earth moving machine/shovel, mechanically driven excavator/dredger, construction, etc. The effect of saving the cost of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

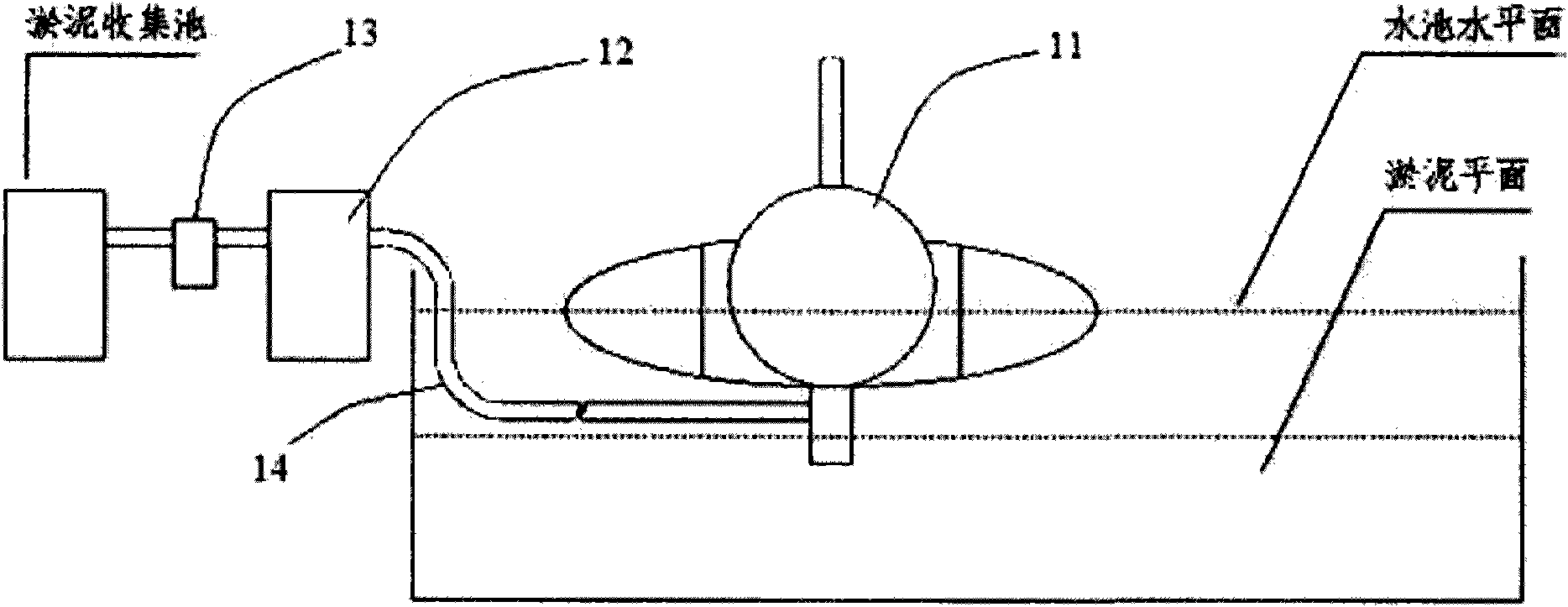

[0017] see Figure 1-3 , The mud suction robot 1 provided by the present invention includes a suction pipe guiding assembly 11 , a suction pipe winding assembly 12 , a mud suction assembly 13 and a suction pipe 14 . The suction pipe guide assembly 11 is the intelligent core of the mud suction robot 1. This assembly can automatically realize forward, backward, left turn and right turn movements in the pool, and can automatically detect the depth of the mud suction and extend the suction pipe 14. into the silt, and send instructions to the silt suction assembly 13 and the suction pipe winding assembly 12 on the bank to control their working modes, so as to automatically suck the silt in the water treatment pond into the designated silt collection pond.

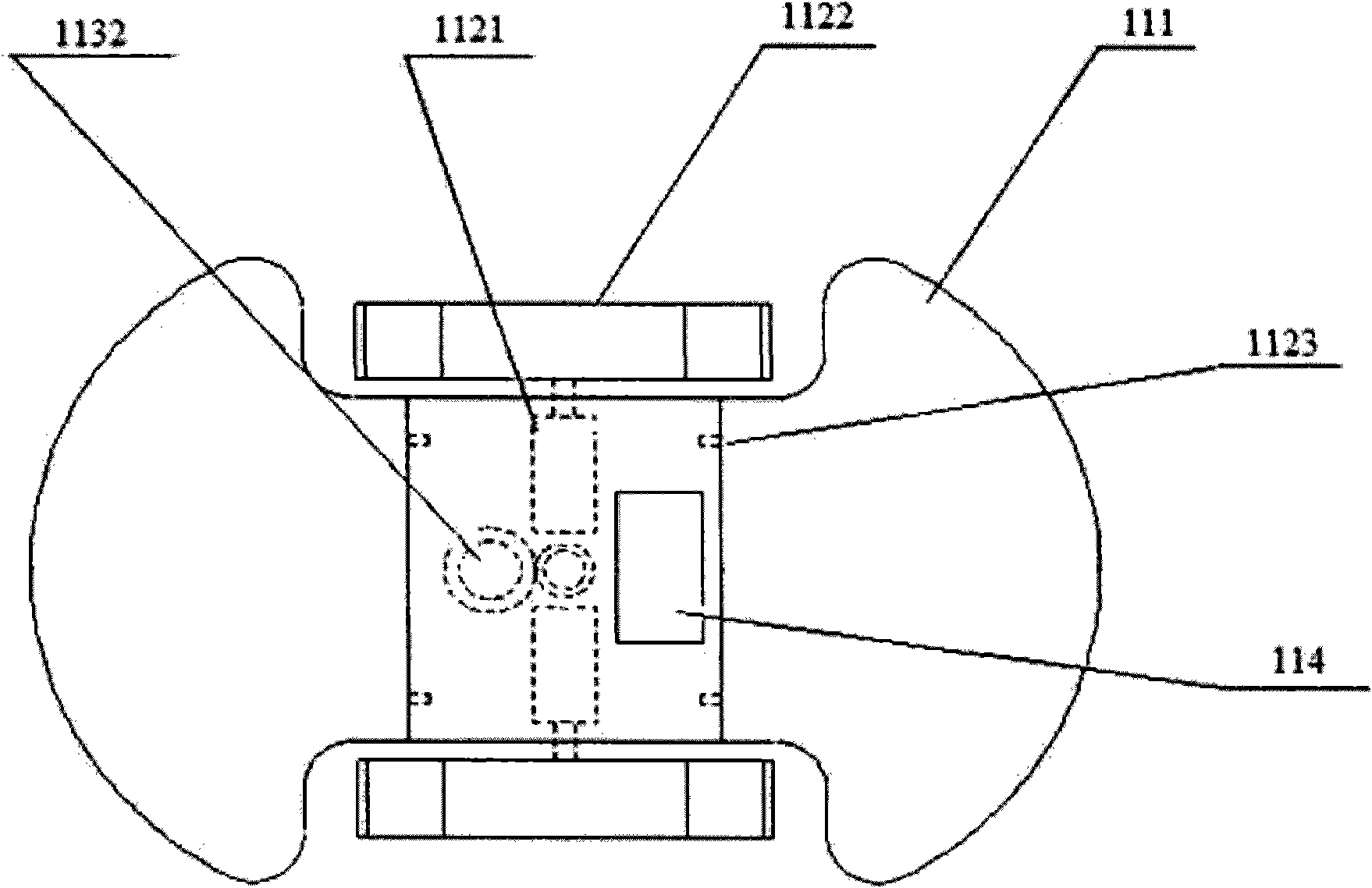

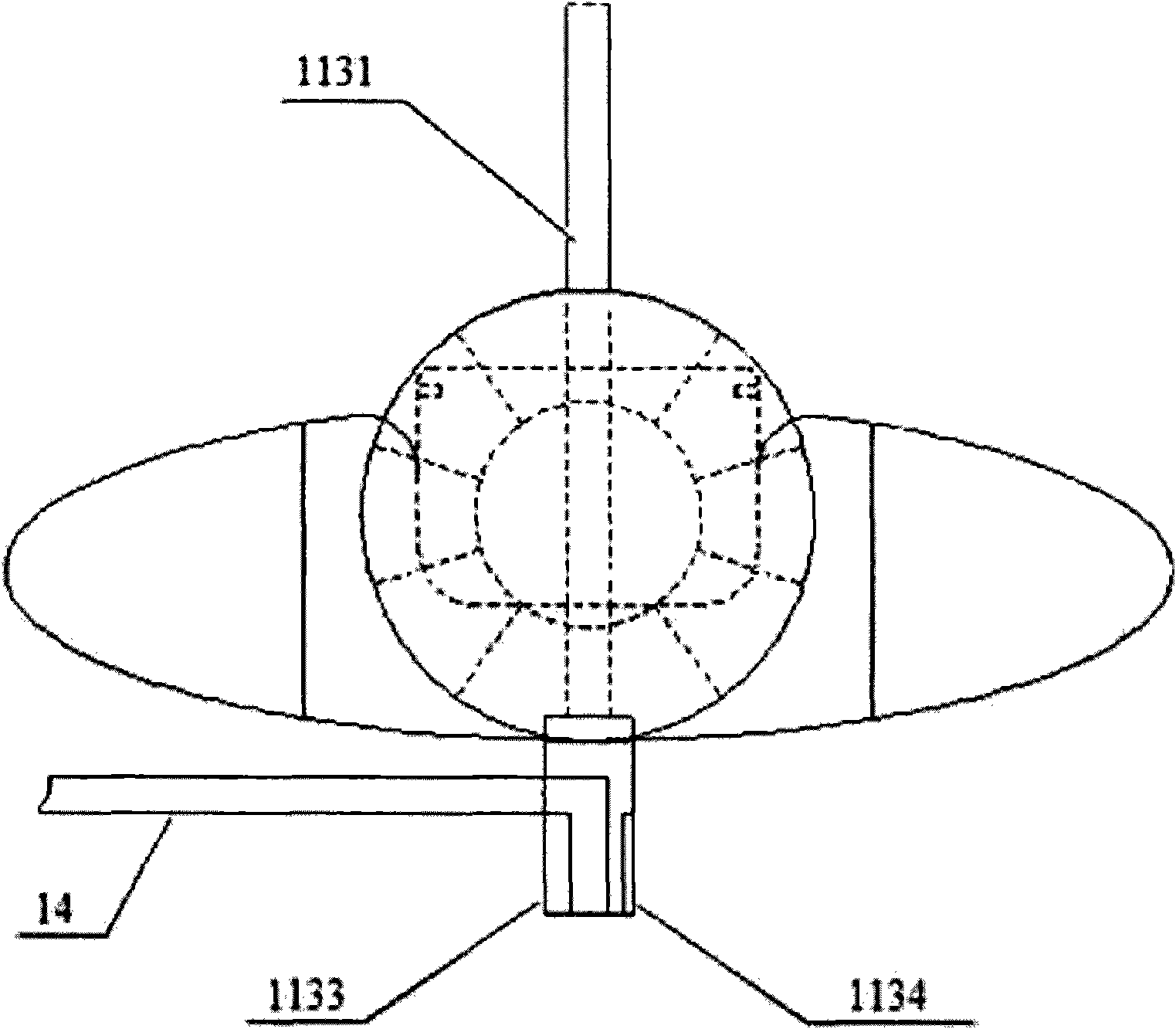

[0018] The straw guiding assembly 11 includes a buoyancy component 111 , an intelligent walking component 112 , a straw depth adjusting component 113 and an intelligent control center 114 .

[0019] The buoyancy component 111 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com