Device for automatically adjusting pressure of flowing gas

A flow gas, automatic adjustment technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems that cannot be realized, cannot obtain high-order harmonics, and poor adjustment effect, so as to improve real-time accuracy , fast response time, stable air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

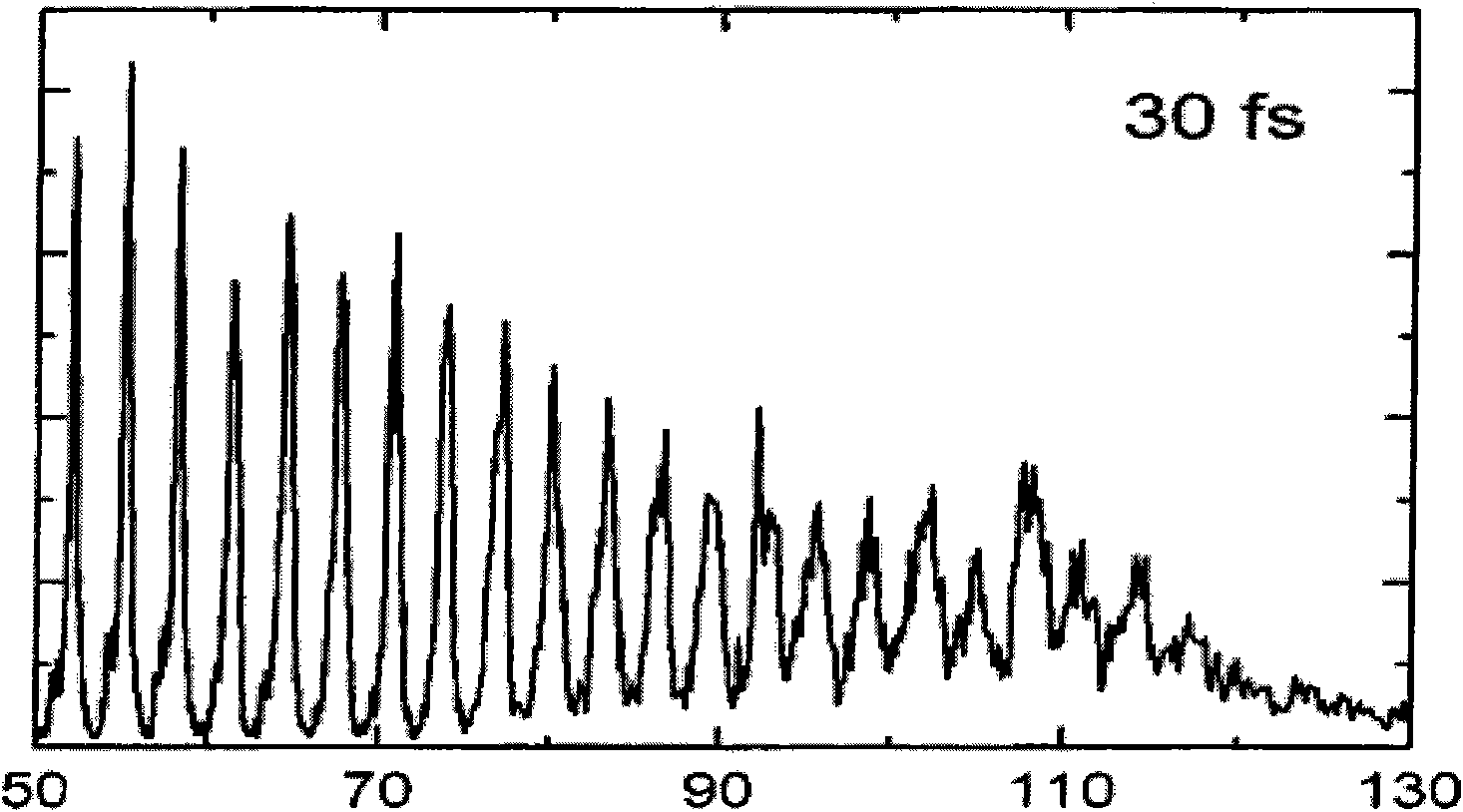

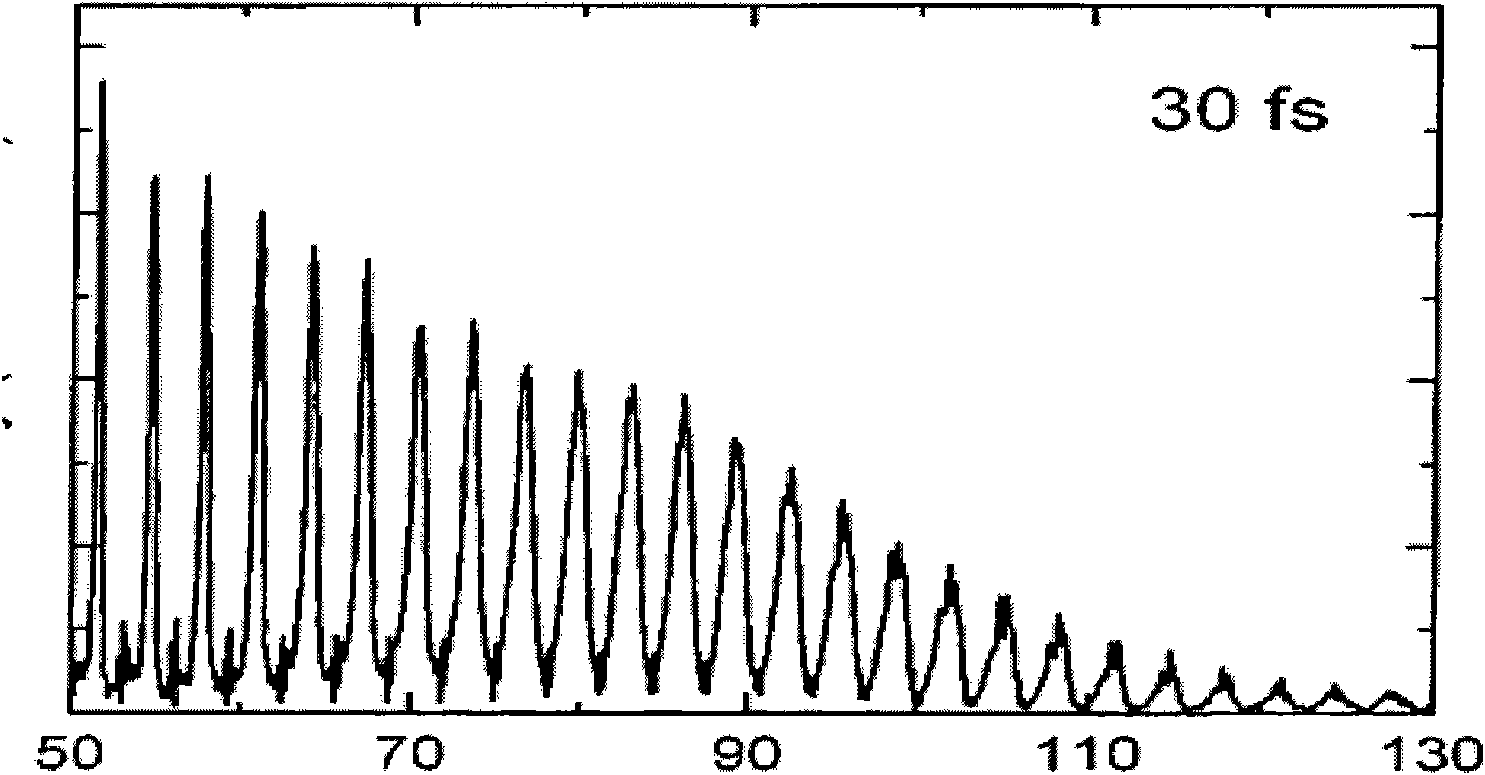

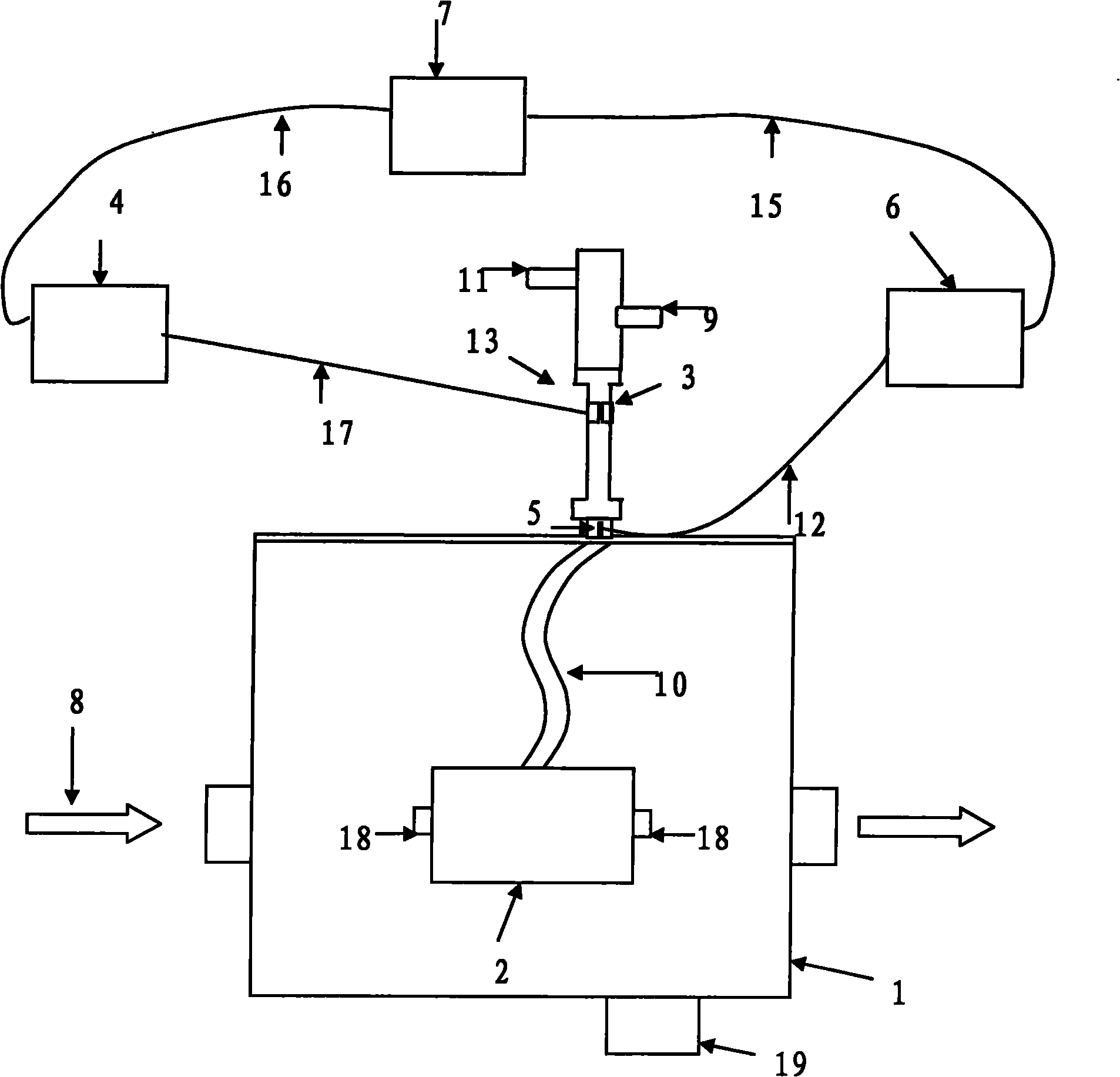

[0021] see first image 3 , Figure 4 , image 3 It is an overall block diagram of the automatic adjustment of the flowing gas pressure in the gas box for the interaction between the supply gas in the target chamber and the femtosecond laser in the embodiment of the automatic adjustment device for the flowing gas pressure of the present invention, Figure 4 It is a structural schematic diagram of an embodiment of the low-pressure flowing gas pressure regulating valve of the present invention. As can be seen from the figure, the automatic regulating device for flowing gas pressure of the present invention includes a vacuum gauge 6 and a valve body. The valve body is a fine-tuning valve body 13. The air valve 9 has a vacuum probe 5 at the air delivery end, and a piezoelectric ceramic valve 3 is also located between the fine-tuning intake valve 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com