Novel low-cost high-efficiency heat radiation large-power LED street lamp and production process thereof

A low-cost technology for LED street lamps, applied in lighting and heating equipment, cooling/heating devices for lighting devices, damage prevention measures for lighting devices, etc., can solve problems such as unstable quality, low production efficiency, and high cost, and achieve reduction Phosphor powder attenuation, solving heat dissipation problems, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

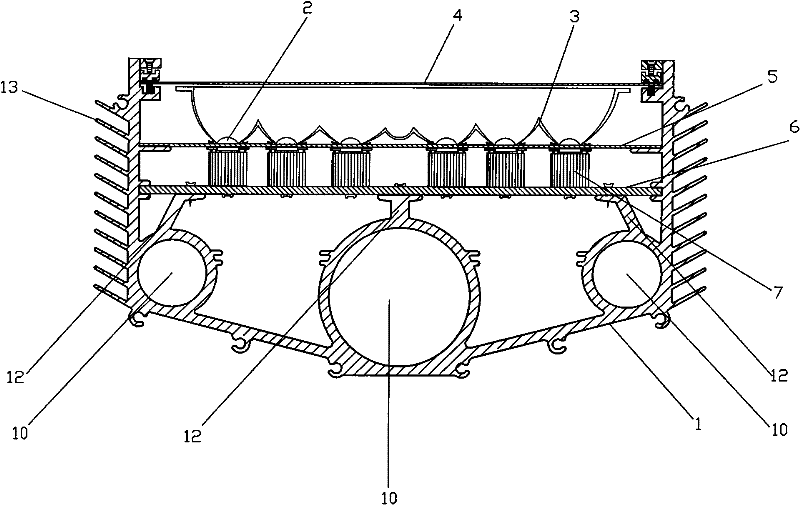

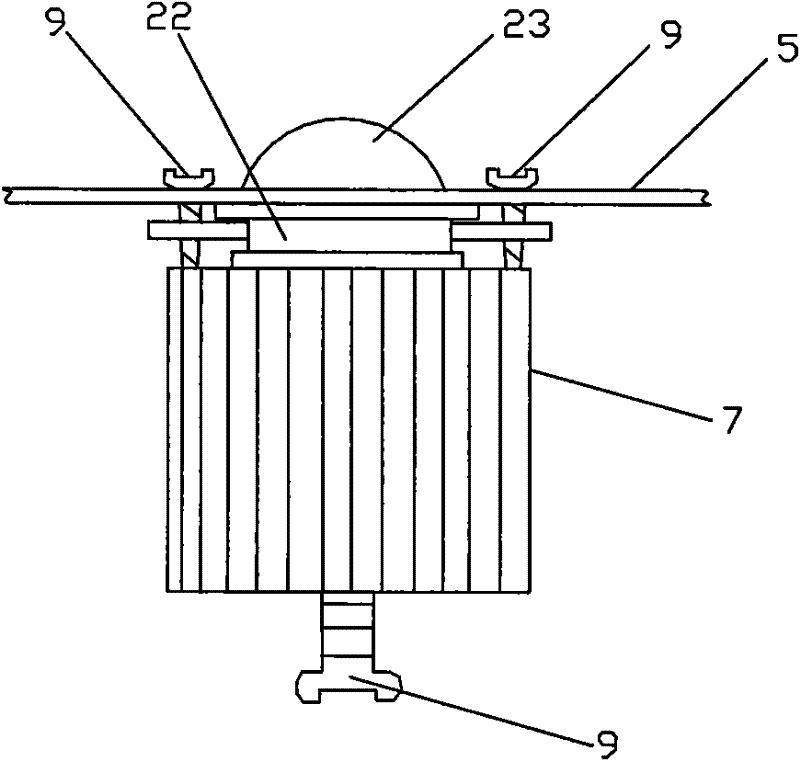

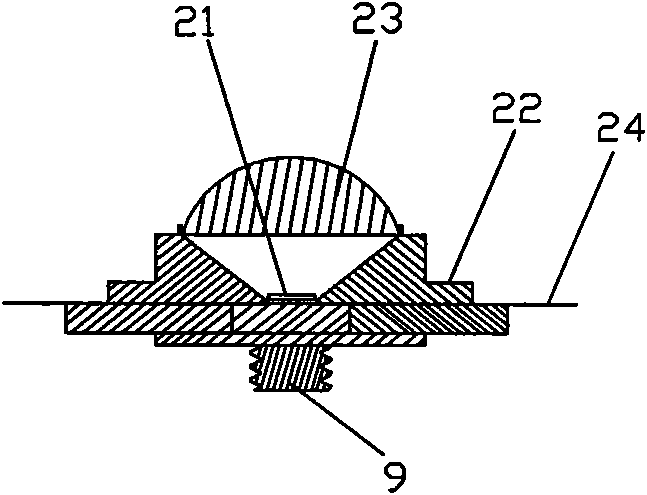

[0032] The specific implementation manner of the novel low-cost high-efficiency heat-dissipating high-power LED street lamp of the present invention is as follows: Figure 1-Figure 6 As shown, it includes a housing 1 and a plurality of LED heat-dissipating and light-emitting integrated tube lamp bead series assemblies 2 arranged in the housing 1. The housing 1 is also provided with a reflector 3 and a light-transmitting body 4. Each LED heat-dissipating and light-emitting integrated tube lamp Bead series assembly 2 includes LED flip-chip 21, all-metal bracket 22 and glass lens 23. The shell 1 and all-metal bracket 22 are made of new materials; the shell 1 is provided with two metal heat-conducting plates 5 and 6 for fixing lamps, and the LED dissipates heat. The light-emitting integrated tube lamp bead series assembly 2 is fixed on one of the fixed lamp metal heat conductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com