Reciprocating grate and working method thereof

A technology of reciprocating grate and grate, which is applied in the combustion method, grate, mobile grate, etc., can solve the problems of reduced combustion efficiency, increased coal seam ventilation resistance, increased coal leakage loss, etc., and achieves increased load capacity. And the effect of service life, reduced floor space, and increased load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

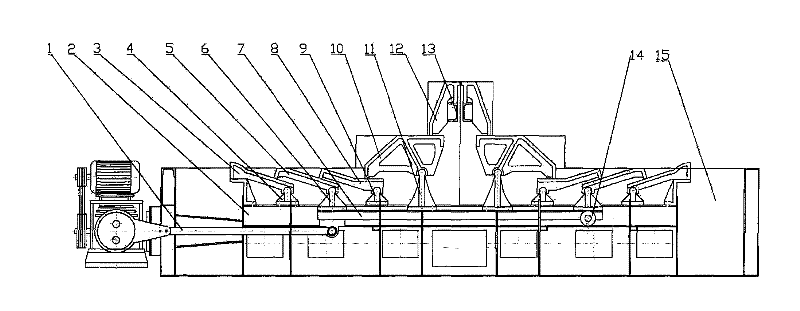

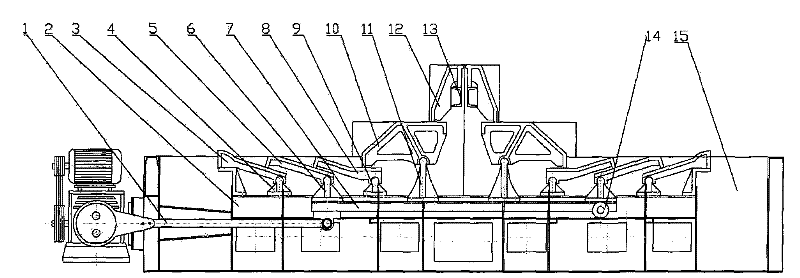

[0015] see figure 1 , The structural composition of the reciprocating grate of the present invention is as follows: the two-way reciprocating mechanical grate is composed of a left-right symmetrical fixed grate assembly, a left-right symmetrical movable grate assembly, a power drive device and a supporting member. In the accompanying drawings, except the power drive device numbered 1 is on the left side of the figure, all other numbered parts are left-right symmetrical arrangement or left-right symmetrical structure. figure 1 The left and right direction of the fire grate is the length direction of the fire grate, that is, the longitudinal direction.

[0016] The fixed grate assembly includes a fixed grate piece and a fixed grate piece support beam, which are arranged symmetrically with respect to the longitudinal center line of the grate support 2 . The fixed grate includes the end fixed grate 3, the middle fixed grate 8 and the middle fixed grate 12; the fixed grate support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com